Hazardous dust, which arises from many sources, from industrial activities to natural events and human endeavours, represents a varied spectrum of airborne particulates. Dust comprises microscopic solid particles suspended or distributed in the air. Different types of dust have varying particle sizes, chemistry, and reactivity. Each has a unique impact on our health and the environment. These minuscule particles, usually invisible to the naked eye, carry harmful substances, including silica, coal dust, asbestos fibres, and various metallic compounds.

As stewards of the environment, we must highlight the often-neglected issue of hazardous dust. Understanding its various forms, pinpointing its sources, and recognising its potential impacts on health and the environment are crucial steps in raising awareness. This knowledge is not just academic; it is a tool for empowerment, enabling individuals and communities to take precautionary actions to protect themselves and their environment.

This comprehensive guide delves deep into the world of hazardous dust, unravelling its classification, examining its different types, and shedding light on the safety measures and compliance strategies essential for safeguarding our health and preserving the environment.

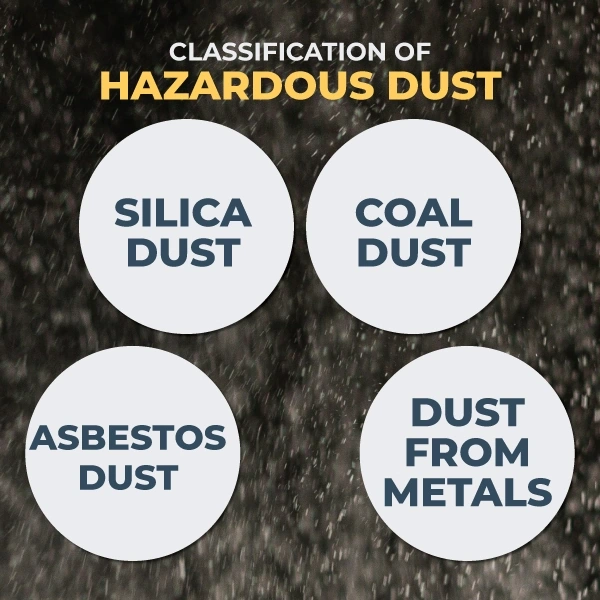

Classification of Hazardous Dust

This dust is not a singular entity but a diverse category comprising various particles, each with unique properties and health implications. In this section, we explore the primary types of hazardous dust – silica, coal, asbestos, and metal dust – and the health risks associated with each.

Silica Dust

Silica dust, the most prevalent form of hazardous dust, is derived from materials like rocks, sand, and human-made products such as glass and ceramics. Its omnipresence in construction and manufacturing makes it a common occupational hazard. Silica particles can deeply penetrate the lungs when inhaled, leading to silicosis, a debilitating lung disease. Silicosis not only impairs lung function but can also be fatal. The microscopic size of silica particles makes them particularly dangerous, as they can evade the body’s natural respiratory defences.

Coal Dust

Coal dust, another prominent hazardous dust, originates from the mining and combustion of coal. It consists of fine coal particles that, when inhaled, can accumulate in the lungs, causing pneumoconiosis, colloquially known as “black lung disease.” This condition is characterised by coughing, shortness of breath, and significant lung damage, impacting the quality of life and leading to severe respiratory distress. The coal industry workers are the most vulnerable to this dust type, necessitating stringent safety measures to mitigate exposure.

Asbestos Dust

Asbestos dust comprises tiny fibres previously used in various products, including building materials and insulation. Its use has significantly declined due to the discovery of its carcinogenic nature. Inhalation of asbestos fibres can lead to mesothelioma, a rare and aggressive form of cancer primarily affecting the lining of the lungs. What does asbestos dust look like is a common concern, as asbestos dust is particularly insidious because of its long latency period; symptoms may appear decades after exposure, making early detection challenging.

The three main types of asbestos are brown asbestos, known as amosite; blue asbestos, known as crocidolite; and white asbestos, known as chrysotile.

Dust from Metals

Metal dust, especially from heavy metals like lead, arsenic, and chromium, poses a grave health risk. When inhaled, these metallic particles can cause an array of health issues, including cancer, neurological disorders, and respiratory problems. Workers in metal processing and manufacturing industries are most at risk. The toxicity of metal dust varies depending on the metal type, with some metals having cumulative effects that manifest over prolonged exposure.

Health Risks of Hazardous Dust

Exposure to hazardous dust can result in a spectrum of health problems, including severe lung diseases (silicosis, pneumoconiosis, mesothelioma), various forms of cancer, neurological issues, and general respiratory complications. The severity of these conditions often depends on the duration and intensity of exposure.

Understanding the classification of hazardous dust and its health implications is essential for effective risk management. Awareness and adherence to safety protocols are vital in protecting individuals from these insidious environmental hazards.

As per HSE (Health and Safety Executive UK), Silica dust is the second most significant cause of lung disease in workers after asbestos, killing over 500 construction workers in the UK every year. Even with such high fatalities, many construction workers are unaware of when harmful silica particles are released.

As per the Study, The outlook for mesothelioma is poor. Unfortunately, only 50% live beyond a year, and only one in 10 people live beyond 5 years after diagnosis.

Metalliferous ores such as silver, uranium and nickel contain toxic dust that adversely impacts the respiratory system. Compounds can also be absorbed into the bloodstream via the alveolar walls.

Poisonous to body tissue and several organs, it can cause severe inflammation of the lungs. The toxic elements can be released mainly through mining activities – copper and zinc also have a powerful impact.

Safety Measures and Compliance

In dealing with hazardous dust, safety measures and compliance are not just best practices but are essential to protect human health and the environment. This comprehensive approach includes engineering controls, personal protective equipment (PPE), respiratory protection, and adherence to regulatory standards.

Engineering Controls:

Engineering controls form the backbone of hazardous dust management. These methods focus on either removing the hazard at the source or isolating it to prevent widespread exposure. In industrial settings, these controls are implemented through various techniques:

- Local Exhaust Ventilation: This system captures dust particles at the source through exhaust hoods and ducts, effectively preventing their spread into the workplace. It’s particularly effective when dust generation is high in sanding, grinding, or cutting operations.

- Enclosure and Isolation: Enclosing processes that generate dust or isolate them in dedicated areas can significantly reduce the spread of dust into more expansive working spaces.

- Wet Methods: Applying water or other liquids during operations like drilling or demolition suppresses dust generation. This method effectively reduces the airborne dust concentration, thereby minimising inhalation risks.

Personal Protective Equipment (PPE):

When engineering controls alone are insufficient, PPE acts as a critical line of defence against hazardous dust:

- Respirators: These are crucial in environments with high dust concentrations. Different filters or cartridges target specific dust types, ensuring adequate protection.

- Eye Protection: Safety goggles or glasses shield the eyes from dust particles, preventing irritation or damage.

- Skin Protection: Protective clothing like gloves and coveralls prevent direct skin contact with dust, reducing the risk of irritation or allergic reactions.

Respiratory Protection:

In environments where dust levels are exceptionally high and other controls are not fully adequate, respiratory protection becomes vital:

- Respirator Selection: Choosing a suitable respirator is critical. Per occupational safety and health guidelines, it should match the specific dust hazard and its concentration.

- Fit Testing and Training: Proper fit testing and training in respirator use are essential to ensure that they provide the intended level of protection.

Compliance:

Compliance with safety regulations is not optional but a legal and ethical necessity. This involves:

- Regular Monitoring and Risk Assessments: Regularly assessing the workplace for dust hazards and monitoring dust levels helps maintain compliance with occupational safety standards.

- Training and Education: Employees should be trained on the risks associated with hazardous dust, proper use of PPE, and emergency procedures.

- Documentation and Reporting: Maintaining records of safety measures, incidents, and compliance efforts is crucial for regulatory purposes.

- Continuous Improvement: Safety protocols should be regularly reviewed and updated based on new research, technology, and regulatory changes.

Conclusion

As we conclude this comprehensive guide on hazardous dust, it’s clear that the silent threat posed by these minute particles is a complex and far-reaching issue that significantly impacts human health and the environment. This pervasive danger, often overshadowed by more visible environmental challenges, calls for our collective awareness and proactive action.

With solutions like Oizom’s real-time air quality monitors, you don’t have to worry about classifying different types of particulate matter. The advanced dust monitor will give you data of all types of dust present in the air promoting you to take smart mitigation actions.