State of Art Technology in Environmental Monitoring

PATENT PENDING - PROPRIETARY

Oizom has years of experience in stimulating innovation by creating groundbreaking technology for environmental monitoring. With IoT-based development approach, Oizom has been able to successfully unlock multiple solutions, catering to various industries.

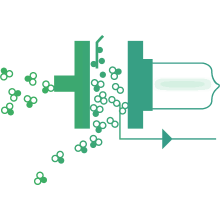

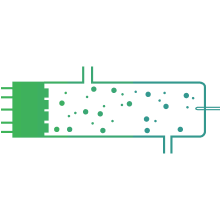

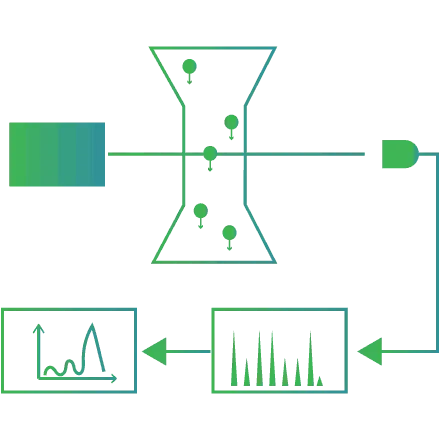

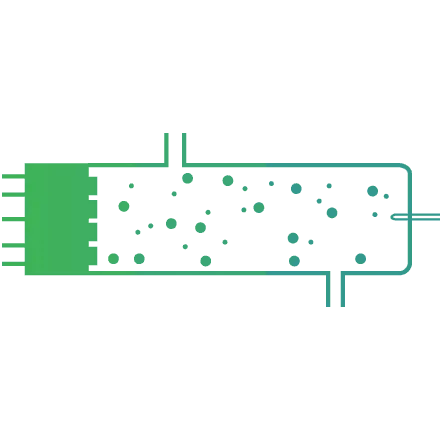

Our sensing technology works on proven working principles like NDIR, Electrochemical Analysis, Semiconductor, Optical Measurement, and Laser-Scattering. As a part of our proprietary ‘Micro Active Sampling’ (e-breathing technology), we have a smartly-designed sample intake and monitoring system inside a controlled environment. This isolates the effect of external environment on measurement to achieve 13% higher accuracy than the industry standards.

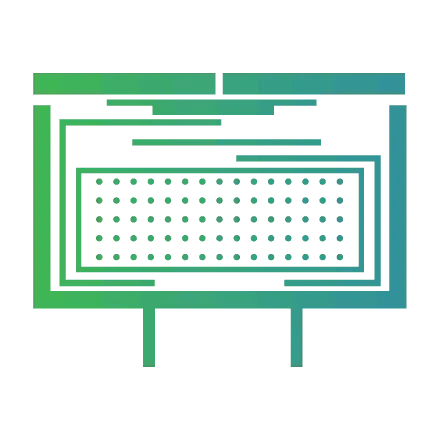

Communication Protocols

GSM / GPRS

Second-generation digital cellular network for global coverage

LoRA

Long Range-Low Power transmission in 433 MHz, 868 MHz, 915 MHz sub-gigahertz bands

NB-IoT

High connection density capability with single Narrow-Band of 200kHz and enhanced Machine-Type communication

MODBUS

MODBUS RTU / TCP & RS485 based industrial grade communication.

WiFi

Wireless Local Area network based on IEEE 802.11 standard

Ethernet

Wired local area network deployment capability for secure data transfer

Sigfox

Wide-reach & ultra-narrowband transmission with upto 140 uplink messages a day, 12 octet payload and 100 bytes/second data rate

LTE

Standard wireless broadband communication for mobile devices and data terminals

Accuracy through Multi-level Calibration

Factory Calibration

All the sensors are calibrated at Oizom factory before dispatching the equipment to check their functioning. It is basically a Bump Test performed to verify that the sensor is working properly for each parameter. All the parameters which the equipment is capable of monitoring like particulate concentration gaseous contaminants, noise, odour, temperature, humidity, pressure, light intensity, etc. are tested here.

Lab Calibration

Oizom equipment are calibrated in the National Accreditation Board for Testing and Calibration Laboratories to ensure data accuracy and eliminate cross sensitivity among the sensors. Calibration is carried out for all the parameters like PM, noise, temperature, humidity, pressure, odour, UV radiations, etc. Gas calibration is done with pure air and calibration gas, at a high concentration range of 1-10 PPM and flow rate of 0.5L/min.

Spot Calibration

Through spot calibration, the equipment is calibrated over the cloud, reducing onsite manpower and maintenance cost. It is a periodic calibration performed quarterly or bi-annually depending on the air quality. Oizom uses a recently calibrated sensor-based system or a third-party system trusted by the client as a reference. The reference system should be a continuous monitoring system. Around 150 data points are collected at the same time-interval to re-calibrate a system on the spot.

Field Calibration (Co-Location)

The sensors are calibrated against a reference station before installation to test their performance in the ambient condition. These reference stations are generally situated near the target locations to calibrate under the required ambient conditions. Around 1000 data points collected at the same time interval is sufficient to calibrate the system. This is an optional calibration and depends on the customer’s requirement.

Low Power Electronics

All the sensors integrated within our equipment have a voltage usage of just 3.3-5V, thus achieving negligible consumption. The average power consumption is 0.6-2.4W (including all the accessories), meaning that the average electricity cost is less than 0.99$/month even if the device is online 24×7 all year round.

Working Principles

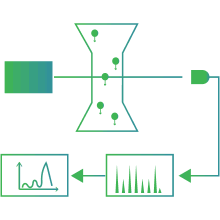

Light Scattering

The sensor emits a laser beam to diffract through the air sample collected in the equipment. The intensity of the beam scattered from the particles provides particle size distribution and concentration.

Electro Chemical

The gaseous emission is treated electrochemically by applying an external potential. Each gaseous molecule like CO2, H2S, CH4 etc. is identified depending on their oxidation or reduction potential.

PID

Photoionization detection method is used to quantify TVOCs. Highly energized UV photons bombard the molecules and make them positively charged. These ionized molecules produce electricity which gives their volumetric concentration.

NDIR

The gases emitted undergo Nondispersive Infrared Radiation where the sample air is subjected to infrared radiation. Different gaseous molecules absorb IR at different frequencies. The amount of IR absorbed gives the volumetric concentration.

Light Scattering

The sensor emits a laser beam to diffract through the air sample collected in the equipment. The intensity of the beam scattered from the particles provides particle size distribution and concentration.

Electro Chemical

The gaseous emission is treated electrochemically by applying an external potential. Each gaseous molecule like CO2, H2S, CH4 etc. is identified depending on their oxidation or reduction potential.

PID

Photoionization detection method is used to quantify TVOCs. Highly energized UV photons bombard the molecules and make them positively charged. These ionized molecules produce electricity which gives their volumetric concentration.

NDIR

The gases emitted undergo Nondispersive Infrared Radiation where the sample air is subjected to infrared radiation. Different gaseous molecules absorb IR at different frequencies. The amount of IR absorbed gives the volumetric concentration.

Data Encryption for Security

We have a very stringent data security policy. MQTT Protocol , REST APIs & OAuth 2.0 token-based encryption is implemented throughout the system. Oizom offers impenetrable data security by deploying SSL Encryption for Web Application.

Software Capability

Cloud Software

Data acquired onsite is transmitted to the Oizom Terminal for analysis through our cloud platform. The results are then reverted to the users in desirable formats.

On-premise

Data can also be stored in the local server as per the customer’s requirements. Data is locally transferred using FTP to Terminal and final output is provided to the user.

Cloud Software

Data acquired onsite is transmitted to the Oizom Terminal for analysis through our cloud platform. The results are then reverted to the users in desirable formats.

On-premise

Data can also be stored in the local server as per the customer’s requirements. Data is locally transferred using FTP to Terminal and final output is provided to the user.