Summary of Blog

This article examines how industries use Oizom devices to monitor air quality, highlighting the air quality monitor’s role in providing accurate data to State Pollution Control Boards (SPCBs). It discusses the effects of industrial air pollution on employees’ health and the environment, highlighting the importance of advanced sensor-based monitoring systems. The blog details how Oizom’s devices use Modbus or API integration to send data to SPCB via authorized partners, helping authorities visualize AQI data and plan effective mitigation strategies. It also discusses the significance of air quality monitoring systems in ensuring worker health, regulatory compliance, and environmental protection. Examples from Adani Power and other sectors demonstrate the practical application and advantages of Oizom’s technology. Finally, the blog underlines the significance of continuous real-time monitoring and proactive steps to manage industrial emissions and protect air quality.

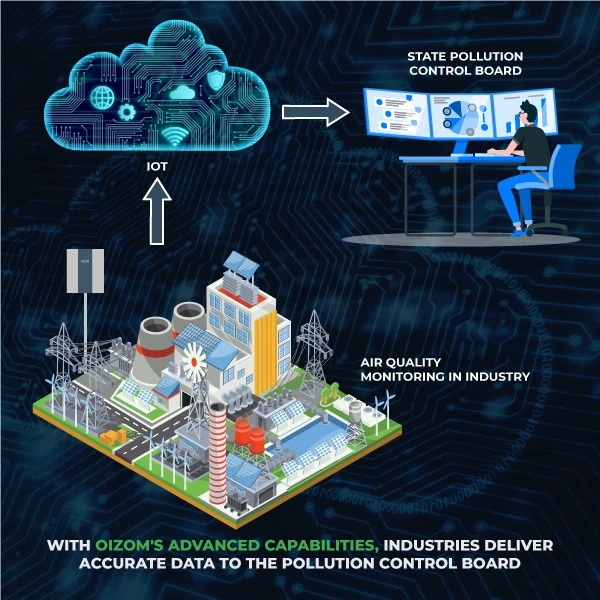

With Oizom's Advanced Capabilities, Industries Deliver Accurate Data to the Pollution Control Board.

Have you ever heard of how industries contribute to poor air quality? If so, it may be because we live in the 21st century, and many people know about industry air pollution and its impact on the environment and human health. Let me ask you a simple question: What comes to mind when you hear the term “industry air pollution”? Here is the basic answer to the above question: Industrial air pollution occurs when dangerous compounds are released into the atmosphere from factories, mining, and transportation. These contaminants can lead to respiratory illnesses, cancers, impaired lung function, and asthma. They can also impact the ecosystem, causing acid rain and climate change.

In this article, I will provide information on how small and large-scale industries monitor air quality with Oizom devices and how air quality data can help the State Pollution Control Board (SPCB) analyze the impact of pollution in real-time and take appropriate actions on industries, or authorities can prepare mitigation strategies to improve air quality in industry.

Importance of monitoring Air Quality in Industries

Industrial air pollution is a major issue that affects individual health and the environment. India’s development has accelerated recently, resulting in increased air pollution and declining air quality. The problem is especially significant in developing nations such as India, where rapid industrialization has increased the number of factories and power plants. Not only do industries cause air pollution, but there are other various sources from which air pollution occurs. Let me share some insights about other sources, too!

Air pollution, which ranges from smoke over cities to smoke inside the home, is a severe danger to global health. Almost all of the world’s population (99%) is exposed to air pollution, which increases their risk of diseases such as heart disease, stroke, chronic obstructive pulmonary disease, cancer, and pneumonia. This is where government bodies come into effect to protect their citizens’ best interests. Ensuring a safe environment is critical for urban residents.

Industrial operations generate a variety of pollutants into the atmosphere, including particulate matter, sulfur dioxide, nitrogen oxides, and other harmful substances. The effects of industrial air pollution on residents of an industrial township can be severe. Long-term exposure to these contaminants can result in respiratory and cardiovascular problems, as well as cancer. It can also cause impaired lung function, increased frequency of asthma attacks, and other respiratory problems. Furthermore, industrial air pollution can contribute to environmental degradation, such as acid rain and climate change, which can have long-term consequences for human health and the ecosystem.

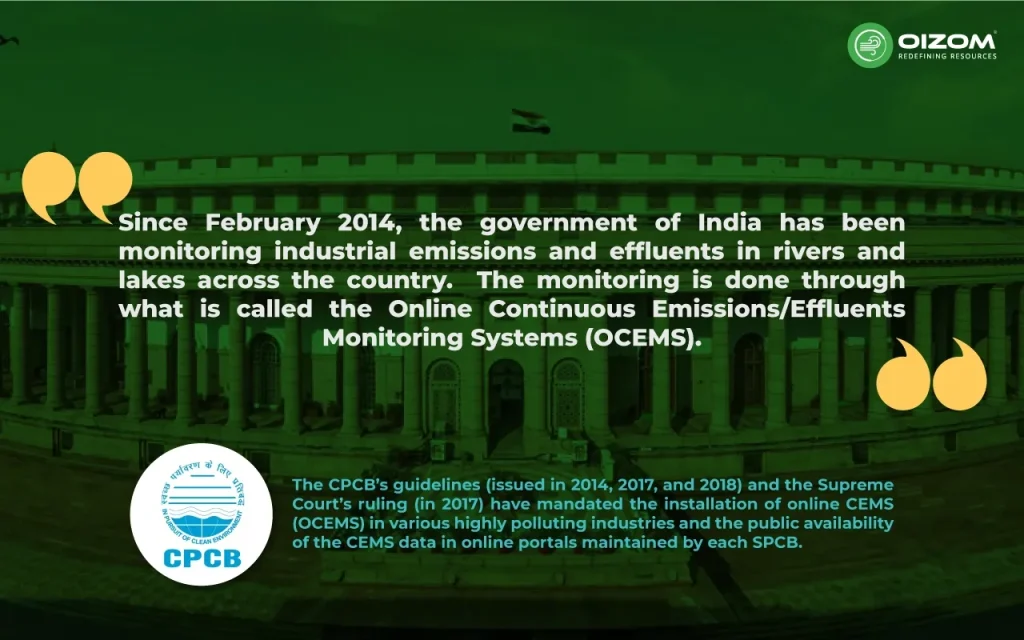

17 categories of industrial units are required to have OCEMS. These include power plants, aluminum, zinc, and copper plants; cement plants; distilleries; fertilizers, iron and steel plants; oil refineries; petrochemicals; and tanneries. The emissions monitored under the OCEMS regulations include particulate matter (PM), CO (carbon monoxide), NOx (nitrogen oxide), SO2 (sulfur dioxide), and fluoride.

In mid-March 2020, talks in Parliament revealed that there were approximately 3,700 OCEMS deployed in various industrial areas throughout the country. A month earlier, the Union administration informed Parliament that the total number of targeted units was 4,245. Meanwhile, as of October 2020, the country had just 234 continuous air pollution sensors (also known as CAAQMS – Continuous Ambient Air Quality Monitoring Systems); the data from these monitors is used to calculate the AQI or National Air Quality Index.

Let me tell you one fact: A new report by Greenpeace has identified the fossil fuel industry as the biggest source of air pollution across Africa. The report found that Africa is home to some of the world’s worst nitrogen dioxide and sulfur dioxide hotspots, all of which are primarily linked to thermal power plants.

Significance of Air Quality Monitoring System in Industries

Air Quality (AQ) Monitoring Systems are critical in industries to maintain worker health and safety, regulatory compliance, and environmental protection. These devices are crucial for detecting dangerous pollutants and giving real-time data to manage air quality successfully. Here are the following reasons why it is important to have Air Quality Monitors:

- Health & Safety: Industrial processes often release pollutants such as particulate matter, volatile organic compounds (VOCs), and gasses like sulfur dioxide (SO2) and nitrogen oxides (NOx). Continuous exposure to these pollutants can cause respiratory problems, cardiovascular diseases, and other health issues among workers. Air Quality Monitoring Systems help identify and control these pollutants, safeguarding employees’ health.

- Monitor Regulatory Compliance: Air quality sensors and other devices allow you to track emissions from industrial sources such as power plants and industries to ensure they follow government guidelines and alter your outdoor activities accordingly. One of the primary advantages of air quality monitoring is that it allows us to ensure that the air we breathe is safe.

- Environmental Protection: Industries are major sources of air pollution, which harms ecosystems and contributes to climate change. Monitoring emissions allows enterprises to discover sources of pollution and implement strategies to lessen their environmental impact. Air Quality Monitoring Systems provide the data required to create and assess the success of pollution-control programs.

- Monitor Climate Change: Changes in weather patterns, such as increased heat waves and wildfires, can impact air pollution levels. By tracking these changes, air quality monitoring can help identify the influence of climate change on air quality and take steps to mitigate it.

- Support Research and Development: Continuous monitoring of air quality helps record pollution and changes in air quality for a long time. Gathered data on air quality is a unique source of inspiration for the research and development of innovative pollution control systems that have the potential to minimize industrial emissions.

In addition, Air quality monitoring systems help industries achieve their sustainability goals. These systems provide feedback for improving strategies and promoting sustainable habits by tracking pollution trends and policy efficacy. This contributes to improved air quality and serves broader environmental goals, such as lowering greenhouse gas emissions and fostering green urban areas.

Challenges in Industries

Pollution-related difficulties affect industrial operations, regulatory compliance, and public perception. Addressing these difficulties is crucial for long-term industrial growth and environmental sustainability. These are some of the following challenges in industries:

- Industrial Pollution: Activity within or close to city limits contributes significantly to air and water pollution. While the city’s development strives to boost economic growth, controlling industrial emissions remains difficult. Implementing stringent regulatory frameworks and introducing cleaner technologies in companies are critical steps toward minimizing this form of pollution.

- Data Management: To effectively control pollution in industries, huge amounts of environmental data must be collected for air quality, analyzed, and managed. Ensuring this data’s accuracy, security, and efficiency pose technological and administrative issues.

- Higher cost of FRM/FEM: You all might be aware of traditional reference grade monitors FRM/FEM. How does it work? And what are the pros of it? Let me share with you what are the cons of FRM/FEM: Traditional FRM and FEM monitoring equipment is expensive, typically costing between $15,000 to $40,000 per monitor. Properly running the instrumentation sometimes necessitates a temperature-controlled environment, and routine calibration and maintenance necessitate specialized experts, resulting in even higher operating costs; the annual cost to maintain a FRM can frequently exceed the significant purchase cost.

How Oizom is helping Industries to monitor air quality accurately and sending the data to SPCB?

The United Nations has created several programs to assist countries throughout the world in reducing air pollution levels. One example is the Global Monitoring System for Air (GEMS/Air), which helped nations develop strategic goals. Their model uses Consortium for Better Air Quality (CBAQd) data. It collaborates with a variety of businesses and public organizations to address pollution. They primarily collect data on air pollution levels. Secondly, they also help raise public awareness about city air pollution levels. The first step is to have an air quality monitoring system; without it, no data can be collected.

However, Traditional air quality monitoring methods, such as manual systems and reference stations, have limitations. IoT air pollution monitoring systems offer a modern solution with various components like sensors, communication modules, microcontrollers, and cloud platforms. These systems provide real-time monitoring, data analysis, and cost-effective deployment.

Oizom is a Smart Air Quality Monitoring Solutions company that offers data-driven environmental solutions for better decision-making. Its various Air Quality Monitoring systems are customizable according to the needs of each environment. Oizom has successfully installed several AQMs in various industries across the globe.

You can read more about Monitoring air quality for the largest Steel Manufacturing Industry, TATA Steel.

Below, you can read more about how Oizom significantly monitors air quality in various industries. Monitoring Air Quality in the Industry with Oizom Devices. The data is pushed to state pollution control boards via authorized vendors or partners through Modbus or API integration. Authorities from the pollution control board can visualize the AQI data on their server. With this data the authorities or agencies can plan mitigation strategies for improving air quality.

Let me tell you a quick fact: The Central Pollution Control Board (CPCB) and CSIR-NCP have launched an NCAP program to certify AQMS sensor-based systems. CPCB validated the sensor-based technologies.

Industry projects by Oizom

Oizom has significantly contributed to many industries. It has been monitoring the air pollution in major industries across India and the globe, including monitoring real-time dust generation within the JCB manufacturing plant, monitoring the air pollution levels in and around the Hazira Power Plant by installing Polludrone Smart, PT Kawasan Berikat Nusantara combat Air Pollution in the Industrial Zones, as there is a need to monitor emissions and air quality from different industry surroundings. Here’s how the industries are monitoring air with Oizom:

Read how Oizom is empowering various industries to tackle air pollution

Reliance Chemical Products Ltd- RCPL faced significant challenges with poor air quality in its facilities, impacting worker health and operational efficiency. The harmful air in the environment risks employee health and reduces productivity. The company urgently needed a solution to monitor harmful gasses, particularly sulfur dioxide (SO2) and methane (CH4), to ensure a safer working environment. The introduction of the Polludrone Pro significantly enhanced RCPL’s ability to manage air quality effectively. By accurately monitoring harmful gas levels, RCPL is complying with environmental regulations and taking proactive steps to ensure the safety and well-being of its workforce.

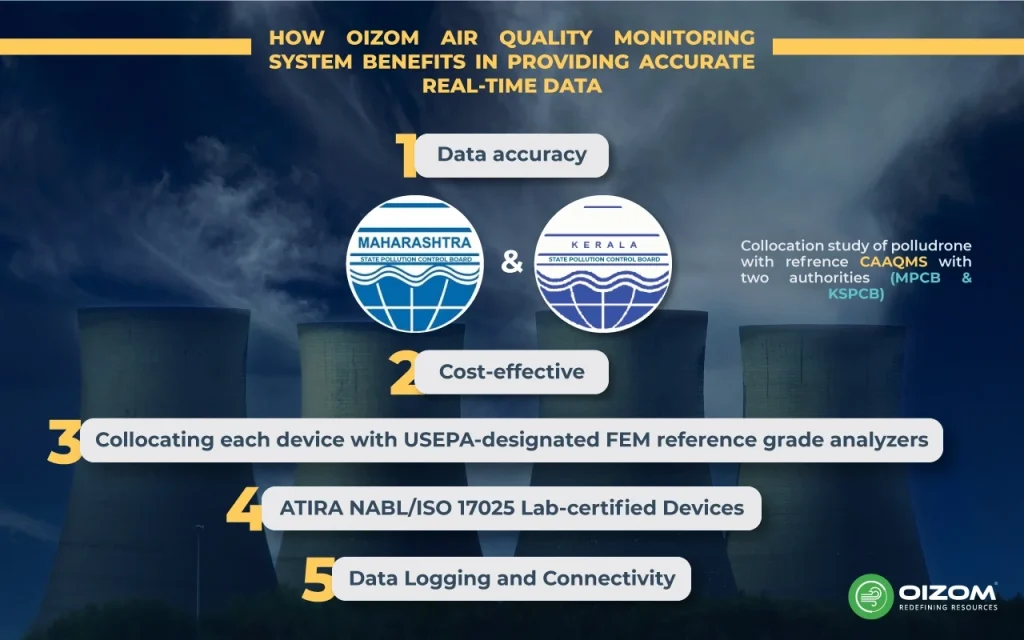

How Oizom Air Quality Monitoring System Benefits in Providing Accurate Real-time Data

One of the most significant measures in reducing air pollution in an industry is to install an AQM, which can correctly detect multiple air pollutants in real-time. With effective AQMs in place, there is no need for guesswork about dust levels, smoke, and hazardous particles in the air. Oizom offers an end-to-end, scalable solution for real-time air quality monitoring and advanced data analytics to help industries pinpoint emission sources. It has numerous benefits, which I’ll discuss in the blog and also discuss how Oizom achieved its data accuracy in air quality monitoring.

Data accuracy (MSPCB, KSPCB)

One of the most critical stages in mitigating/reducing air pollution is having an AQM capable of reliably detecting numerous factors. Instead of guessing the smoke and dust levels, it can provide governmental bodies with an objective estimate of air pollution levels. This article will share how Oizom achieved data accuracy via collocating research studies.

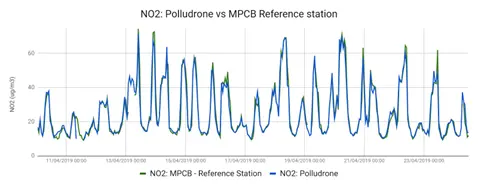

Collocation study of Polludrone & a reference CAAQMS (Maharashtra Pollution Control Board)

- The collocation study was conducted between Oizom’s Polludrone and the Continuous Ambient Air Quality Monitoring (CAAQM) Station of Maharashtra Pollution Control Board (MPCB) at Bandra, Mumbai. This study aimed to validate the sensor-based air-quality monitoring system with internationally approved FRM (Federal Reference Methods) systems.

- With an impressive R2 of more than 0.9 with CAAQM’s FRM, Polludrone proves its reliability in Mumbai’s tropical/coastal climate and can accurately monitor air pollution, even at lower concentrations.

- This performance meets the recommended precision and accuracy error metrics from the US EPA Air Sensor Guidebook for personal exposure (Tier III: Supplemental monitoring and Tier IV: Personal Exposure) monitoring.

Polludrone data with (CAAQM) Station

| Parameter | R2 | RMSE* | Parameter | R2 | RMSE* |

|---|---|---|---|---|---|

| PM2.5 | 0.75 | 4.96 (μg/m3) | NO2 | 0.94 | 3.68 (μg/m3) |

| PM10 | 0.77 | 15.95 (μg/m3) | SO2 | 0.92 | 0.64 (μg/m3) |

| CO | 0.97 | 0.039 (mg/m3) | O3 | 0.94 | 4.84 (μg/m3) |

| NO | 0.93 | 10.85 (μg/m3) | -- | -- | -- |

Collocation study of Polludrone & a reference CAAQMS (Kerala State Pollution Control Board’s)

- Oizom conducted a collocation study to evaluate the performance of Polludrone against the Continuous Ambient Air Quality Monitoring (CAAQM) Station of Kerala State Pollution Control Board (KSPCB) at Thiruvananthapuram. This study aimed to validate the sensor-based air-quality monitoring system and its accuracy in measuring pollutants like PM2.5, PM10, and various gases with reference grade analyzer systems.

- Air-quality data monitored by both systems were compared for 25 days. During this study, polludrone was greatly correlated with the reference station for most pollutants in Kerela’s tropical/coastal climate. The average RMSE (Root Mean Square Error) was around 5.68 units for 24-hour measurements and 11.43 for 1-hour measurements (taken with reference as a base). The study suggests that Polludrone can be a reliable and potentially cost-effective alternative for air quality monitoring. With careful data management and calibration using advanced machine learning models, sensor-based monitoring systems can significantly improve the ability to resolve spatial heterogeneity in air pollutant concentrations.

Polludrone data with CAAQMS

| Parameter | RMSE (24 hr avg) |

|---|---|

| PM2.5 | 12.53 µg/m3 |

| PM10 | 5.35 µg/m3 |

| NO | 3.64 µg/m3 |

| NO2 | 7.19 µg/m3 |

| O3 | 8.12 µg/m3 |

| SO2 | 2.83 µg/m3 |

| CO | 0.10 mg/m |

Cost-effective

- While safety should never be compromised, budgetary constraints are real. Balancing the necessity for accuracy, responsiveness, and other qualities against available funds might help to guide the decision. However, always favor critical features over price.

- Low-cost sensors are valuable for establishing sensor networks because they are more affordable in buying and operations costs, flexible in deployment, and scalable. They also can potentially complement reference-grade monitors in the region with more data points.

- Oizom’s air quality monitoring devices are reliable and accurate, providing a more cost-effective alternative to existing reference stations. Unlike expensive reference stations, which can hinder implementation due to their high cost and occupancy. Oizom’s technology offers a financially practical solution while maintaining performance. This low cost enables more deployment, resulting in more thorough air quality data collecting and proactive environmental management. With Oizom, communities can now afford to monitor air quality effectively, achieving the goals of a healthier environment in smart cities, industries, construction sites, and so on.

Collocating each device with USEPA-designated FEM reference grade analyzers

To get optimum data accuracy and empower Industries with accurate air quality monitoring, each Oizom device is calibrated as per the international guidelines. It is followed by a collocation calibration against reference stations with analyzers to account for the impact of outside environmental factors and validate the devices’ reproducibility. Oizom has a custom-built reference station with USEPA-designated FEM reference grade analyzers. The reference station can accommodate up to 40 Oizom units simultaneously, enabling further assessment of intra-model variability using statistical measures like mean, median, and standard deviation. This ensures our device provides dependable real-time air quality data and safeguards the system’s accuracy.

ATIRA NABL/ISO 17025 Lab-certified Devices

Each Oizom device gets a third-party calibration certificate. We have established an advanced calibration facility in collaboration with ATIRA, an esteemed research association based in Ahmedabad, with a NABL / ISO 17025-certified environment laboratory. ATIRA was founded by Vikram Sarabhai (the founder of ISRO) in 1947 with Ahmedabad’s textile leaders and co-founder Kasturbhai Lalbhai. Through this collaboration, every Oizom device undergoes extensive calibration, and ATIRA issues each device a calibration certificate.

Data Logging and Connectivity:

- Modern monitors often come with features that allow for data logging and connectivity. These features can benefit long-term trend analysis, remote monitoring, and integration with other safety systems.

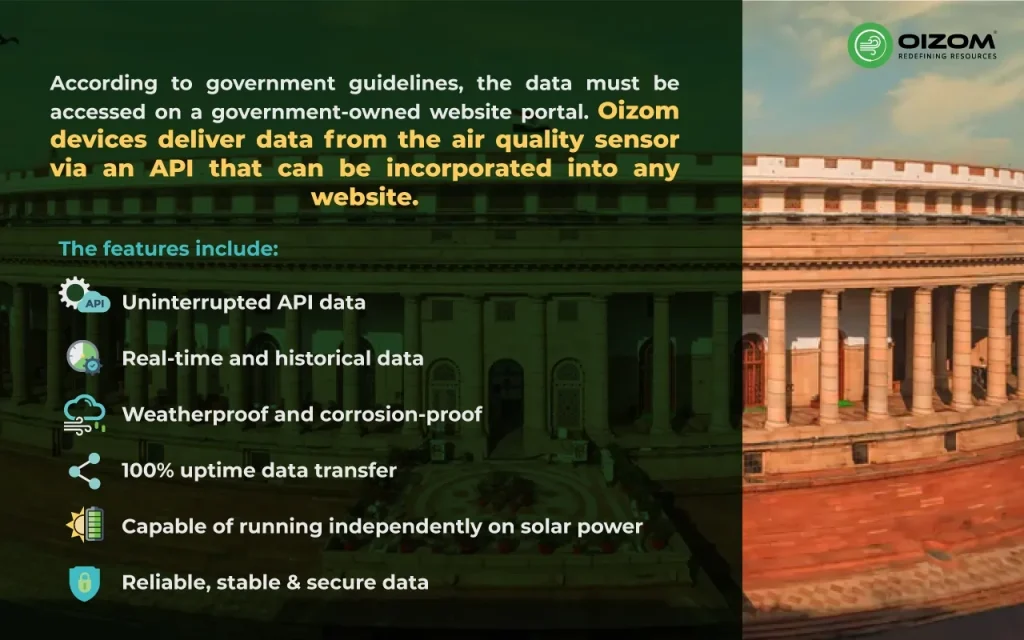

- Regarding data transmission, our devices exhibit remarkable flexibility, supporting a wide array of Wired and Wireless channels. They are equipped to communicate wirelessly using GSM, GPRS, 3G, 4G, WiFi, LORA, LTE, and SIGFOX technologies. For wired connectivity, they offer reliable Ethernet, Modbus, RS-485, and RS-283 options.

- The crucial data on ambient air particulates collected by our devices are efficiently transmitted to the Oizom Cloud, which can operate on either Shared or Private Infrastructure. This data is instrumental in powering diverse data solutions tailored to specific end applications.

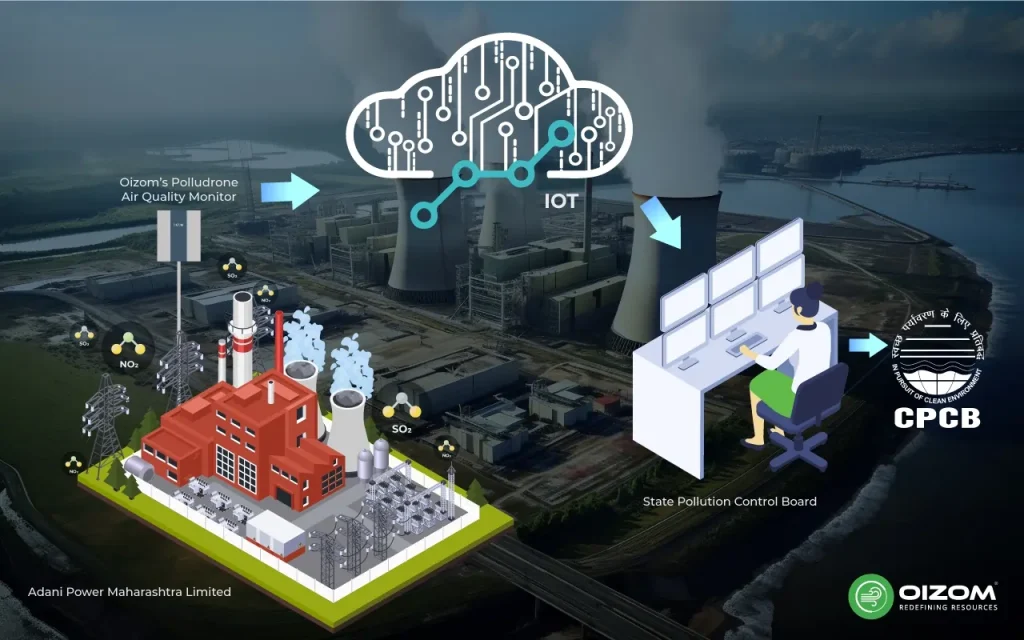

How Oizom devices’ data is pushed to CPCB

Regulatory bodies such as the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) are pivotal in setting guidelines to monitor and control emissions. The government of India has recognized the problem and has come up with a solution for air pollution. For a better understanding, refer to this press release.

Here’s an example of how Oizom devices push data to the CPCB: Imagine an industry monitoring air quality, and they use Oizom devices to collect data. Data is sent to state pollution control boards via authorized vendors or partners of SPCB using Modbus or API integration. The data is transferred to the pollution control board authorities from the Oizom devices’ hardware. It can monitor real-time air quality data, and no data manipulation can be done. Let me walk you through this process to clarify how it all works.

Our client, Adani Power Maharashtra Limited, is the largest coal-based Thermal Power Plant which is located in the state of Maharashtra, India. The plant has a capacity to generate 3300 MW power through its 5 units of 660 MW capacity. Thermal power plants often have high levels of suspended particles and hazardous gasses, such as SO2, NO2, etc. Because the thermal power plant is close to the community, it was critical for the company to monitor suspended PM2.5, PM10, SO2, and other gasses. It was also in their interest to reduce pollutants as per CPCB recommendations. To achieve this, they required an accurate air quality monitoring system.

Oizom offered Polludrone Smart to the Adani Thermal Power plant unit in the Tiroda to monitor the dust and toxic gasses emitting from the plant to the surrounding city. Polludrone also comes equipped with data analyzing and visualization software that can keep track of the historical data and trends of the air pollutants emitted from the steel plants. Moreover, the polludrone can generate a report, which helps send reports in a timely manner to authorities like the State Pollution Control Board; further from SPCB, the data is pushed to the Central Pollution Control Board.

Oizom’s environmental monitoring devices used modern data loggers to collect and transmit essential data to the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCB). These data recorders are critical for correctly recording air quality and other environmental indicators, assuring regulatory compliance. Integrating Oizom’s technology with the CPCB and SPCB platforms allows real-time data access, resulting in fast and effective environmental management decisions. This facilitated data transfer not only aids monitoring efforts but also improves the accuracy of pollution control methods, resulting in a healthier environment.

Conclusion

Finally, my discussion on industrial emissions revealed how they significantly impact climate change. Industries are the top contributors to air pollutants, and various industries contribute various types of toxic gases into the atmosphere. In this regard, an air quality monitoring system has proven effective because this IoT-enabled smart device can detect pollutants and toxic components in industries and neighborhood areas. I hope this article clarifies how small and large-scale industries use Oizom devices to monitor air quality accurately and provide reliable data and how the data is sent to state pollution control boards, enabling officials and decision-makers to identify pollution hotspots and implement targeted interventions. To summarize, AQMs are the ultimate resources for combating air pollution and assisting authorities in implementing data-driven interventions to maintain ideal air quality levels in industry zones. Finally, this will help to achieve Sustainable Development Goals 3, 9, 11, 13.

A sensor-based air quality monitor uses sensors to detect and measure air pollutants like particulate matter and gasses, providing real-time air quality data.

Air quality monitors measure air pollutants effectively, helping individuals and authorities make health and safety decisions. Their accuracy depends on the monitor's quality.

Industry air pollution refers to releasing harmful substances into the atmosphere by manufacturing and production processes. These pollutants include glass, particulate matter, and chemicals that can harm human health and the environment.

Yes, national and international regulations set limits on industrial emissions. Compliance with these regulations is mandatory to minimize the impact on air quality and public health.

The main function of a State Pollution Control Board (SPCB) is to enforce environmental regulations, control pollution, and ensure air and water quality within the state.

Air quality is monitored using instruments like gas analyzers, particulate counters, and sensor-based monitors.

Air quality is measured using infrared spectroscopy, gas chromatography technologies, and various sensor technologies, such as laser scattering, electrochemical analysis, Nondispersive Infrared Radiation, and Photoionization detection.

CPCB (Central Pollution Control Board) is India's national body enforcing environmental standards, while SPCBs (State Pollution Control Boards) enforce these standards at the state level.