The last couple of centuries have shown unprecedented records of technological advancements. Post-industrial revolution, development has soared high into the sky. Population, unemployment, and poverty have rapidly increased. Industries prove to be a lifeline for them, generating employment opportunities. According to the World Bank database industries account for 23.083% of the total employment around the world. However, global issues like climate change and global warming are worsening due to industrial emissions. The increase in industries has caused the ambient air to degenerate drastically. Industries emit pollutants such as sulfur dioxide, nitrogen oxides, dust/particulate matter, etc. Industries are major sources of dust pollution. Industrial dust monitor helps in the real-time monitoring and reduction of dust concentration.

According to India’s National Ambient Air Monitoring Programme (NAMP) particulate matter monitoring PM10 and PM2.5 are the major challenges in air pollution. The report explained that particulate matter was majorly responsible in breaching National Ambient Air Quality Standards. These particulate matters ranging from the size of 1 micrometre to 100 micrometres collectively can be classified as dust. The dust particles are also alternatively coined as Suspended Particulate Matter(SPM) and Respirable Suspended Particulate Matter (RSPM). The National Clean Air Programme NCAP identifies industries as one of the major sources of dust pollution. It further aims to increase the number of dust monitors across the country. An increase in the number of Industrial dust monitor helps in better compliance and regulation. It further aids in a better understanding of source contribution, identifying hotspots, and carry out health exposure studies.

CONTRIBUTION OF INDUSTRIES IN DUST POLLUTION

The majority of the industries are responsible for overall poor ambient air quality. The dust intensive industries are construction and mining, thermal power plants, and cement industries. In addition, Other secondary contributors to particulate emissions are chemical industries, stone crushing, and refining industries, petroleum refineries, etc.

Construction and mining sites are chief fugitive dust pollution sources. Constant excavation activities, loading, and unloading of the waste cause spikes in the dust concentration. Hence, a network of outdoor dust monitors helps to monitor the sources of dust generation. A detailed explanation of dust monitoring at construction sites can be found here.

The raw materials used in stone crushing, refining, and cement industries are inclined towards generating dust particles. For instance, activities like open crushing, drilling, sand filtering, etc cause dust generation. Hence, the dust particles remain in suspension at human breathing levels causing severe pulmonary diseases.

Coal is the most commonly used fuel in boilers and incinerators. Industries that use coal as a raw material are responsible for higher particulate pollution. Industrial dust monitoring becomes mandatory for Industries like thermal power plants, chemical industries, petroleum refineries, etc.

Thermal power plants heavily consume coal as their primary fuel.

OTHER INDUSTRIES

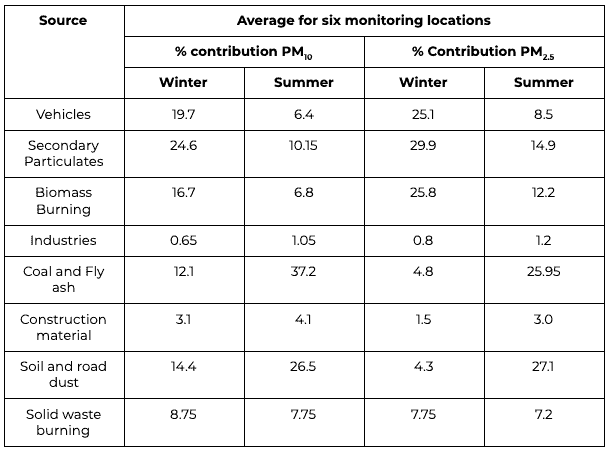

Other industries such as chemical industries, petroleum refineries, steel refineries, foundries, etc cause particulate pollution. Inefficient boilers generate a higher amount of fly ash. This coal fly ash accounts for 37.2% of total PM10 and 25.95% of PM2.5 concentration in summer. Industrial dust monitors help in validating these findings and planning the mitigative strategies.

‘Black Carbon’ is emitted from the thermal power plant, petroleum refineries, and chemical industries. It has huge global warming potential and climate change implications. It is also highly dangerous for human health. Industrial dust monitor helps to keep track of black carbon and design its counter control measures.

NEED OF INDUSTRIAL DUST MONITOR

As established earlier, all industries combined contribute to nearly 40% of the dust pollution. There are huge health implications due to increased dust concentration. According to the report of WHO, finer dust is responsible for the death of nearly 7 million each year. Dust particles can easily penetrate into the respiratory system causing fatal diseases. As a result, people suffer from stroke, heart disease, lung cancer, respiratory infections, asthma, and pneumonia.

Such gruesome negative health effects draw attention towards developing a robust dust monitor system. In humid areas, this dust quickly transforms into smog and fog which reduces visibility. Such reduced visibility increases the threat of major accidents in the city.

Industrial dust monitoring helps in generating a generalized idea of the PM concentration in the study area. It helps in identifying the major pollutant as PM2.5 and PM10. Additionally, placing PM10 monitors and PM2.5 monitors can save monitoring costs. Dust also gets easily dispersed due to wind. It is a good thing as dispersion decreases the dust concentrations. On the contrary, in the presence of a heavy dust source like a construction site or an industry the dust gets carried away to the nearby proximity.

People living in such areas near to industries are highly affected due to it. According to a study in Delhi, industrial emission dispersion affects more people in the summer and winter seasons. In such cases, it is necessary to deploy the industrial dust monitor in the upwind and downwind locations of the industries. In case of the presence of a community or society near the industry, it is beneficial to put an outdoor dust monitor.

ROLE OF INDUSTRIAL DUST MONITOR IN REGULATION AND COMPLIANCE

Increased dust pollution endangers human lives and the surrounding environment. Regulatory authorities frame guidelines and standards for industries to comply with. This results in reduced dust pollution. Dust monitoring acts as the first step to curb dust pollution and plan mitigative strategies. However, there is an inadequate number of dust monitor systems in India and in several other countries.

Industrial dust monitor helps in quantifying the dust concentration in the industries and the surrounding receptors. An industry is liable to monitor the ambient air quality at the industry site and nearby areas under the Environmental Protection Act, 1986, India. It is also mandatory for the industry under EIA notification, 2006 to submit a half-yearly compliance report to the government authorities. The compliance report includes monitoring air quality in the industry and in the nearby vicinity. Industrial dust monitor deployed at such locations helps in preparing the compliance report and improve the ambient air quality. Industries have to prepare an Environmental Management Plan (EMP) to decrease the overall air pollution and avoid any major mishaps. Monitoring air pollution is an integral part of the plan. Industrial dust monitors generate real-time data that helps in generating alerts in case of emergencies.

For the health and safety of the workers in the industry, it is necessary to satisfy the OSHA’s standards of pollution exposure limits. Dust pollution is capable of causing serious diseases. Therefore, industrial dust monitor within the premises helps in regulating the exposure of the workers to dust pollution.

Data collected from the industrial dust monitors help the regulators and policymakers to draft new policies. Therefore, location-specific ambient air standards can be prescribed in certain sensitive areas.

Automated Environmental Dust Solutions

Real-time data monitoring through a robust network of industrial dust monitors helps in dust suppression. Since the dust monitoring systems continuously monitor dust concentration (PM1, PM2.5, PM10, PM100), the system red flags the breach in National Ambient Air Quality Standards. The red flags turn on the automated dust suppressors integrated with the monitoring device. As soon as the ambient air is within the standards, the suppression system stops automatically. Dust suppressors such as mist cannons, water sprinklers, etc. can be easily automated. It takes timely actions and preserves resources and energy. It significantly reduces outdoor dust pollution which poses a threat to the workers and the people living in nearby areas.

The exposure limits prescribed by OSHA is used to set the threshold limits. One can design an efficient automated system using low-cost sensor-based industrial dust monitors. The monitoring data also helps in better process control, fuel conservation, and efficient fuel consumption. The system helps the industry achieve its committed goals to curb dust pollution. Additionally, you can find more on data-driven environmental automation in OIZOM’s Whitepaper.

OIZOM’S OFFERING FOR DUST MONITORING SYSTEM

OIZOM’s industrial dust monitoring device Dustroid measures PM1, PM2.5, PM10, and PM100 along with the weather data to study dust dispersion. Dustroid can also serve as an independent PM10 monitor and PM2.5 monitor. More on the importance of particulate monitoring can be found here.

OIZOM’s devices provide high-quality monitoring data at an economical cost. Further data integration with various platforms results in the generation of dynamic pollution maps.

Moreover, OIZOM’s industrial dust monitors integrated with automated dust suppression systems at thermal power plants, mechanical workshops, construction and mining sites, etc. provide a holistic solution.

OIZOM’s PM monitors are a perfect choice for monitoring PM2.5 and PM10 concentrations in real-time. You can read more about our solution in the related products section below.

For any dust monitoring requirement, you can contact us.