key Takeaway Points

- The blog discusses improving air quality in factories for the environment and worker health.

- It offers strategies such as tackling pollutants at the source and implementing energy-saving technologies.

- Regular air quality monitoring is essential to track emissions and ensure compliance with regulations.

- Controlling dust generated by manufacturing operations is critical for good indoor air quality.

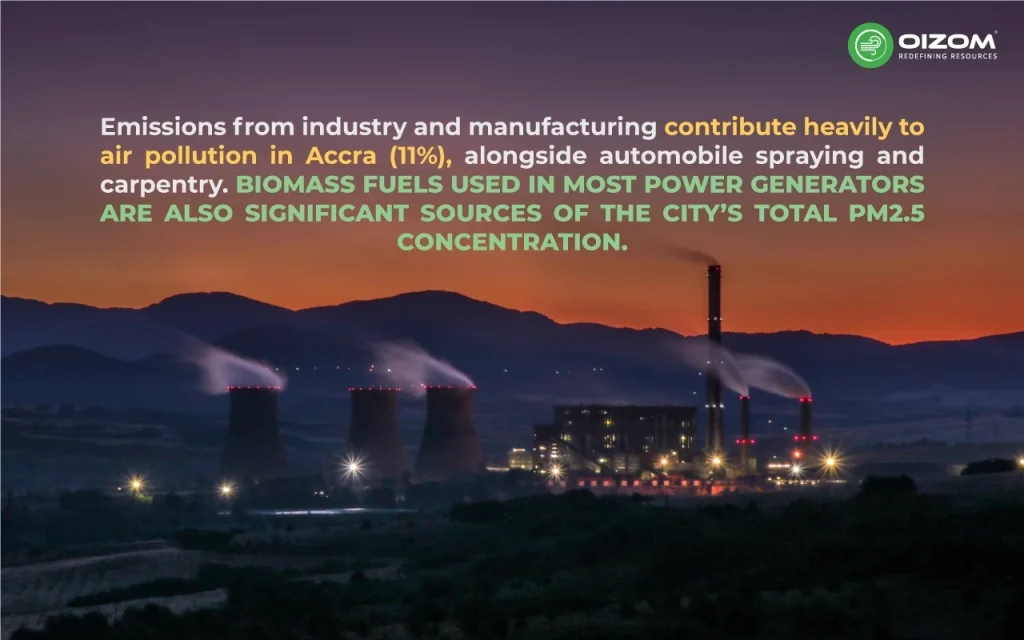

- A real-world example of industrial emissions contributing to air pollution in Accra, Ghana is provided.

- Following these strategies helps reduce environmental impact and improve worker health and safety.

How to improve air quality in factories

Have you ever imagined how workers or employees in factories are impacted by air quality?

Let me give you one fact about how much it affects the workers:

When working on or managing an industrial project, air quality is critical. Poor workplace air quality can induce sickness and disease and severely affect workplace productivity, human health, and safety.

This is why factories, workplaces, and industrial facilities must always proactively improve and preserve air quality and safety. In this guide, you will explore how to improve industrial air quality with various strategies to reduce pollutants at the source, implement air filtration systems, and monitor air quality regularly in factories with oizom devices.

Strategies to Reduce Pollutants at the Source

Reducing pollutants at the source is an important step toward creating a more sustainable environment. Here are three main ways to consider:

Energy Efficiency

Improving energy efficiency is one of the most efficient strategies to cut pollution. This technique optimizes energy use in buildings, manufacturing processes, and transportation to reduce energy consumption and emissions. Implementing energy-efficient technology such as LED lighting, high-efficiency heating and cooling systems, and energy management systems can considerably reduce energy consumption and, as a result, pollution emissions. Encouraging energy-saving behaviors such as shutting off unused electronics and properly maintaining equipment is also important.

Renewable Energy

Transitioning to renewable energy sources is crucial for reducing our dependence on fossil fuels, which are major drivers of air and water pollution. Solar, wind, hydro, and geothermal power are clean options that emit little to no pollutants. Communities and countries may minimize their carbon footprints and encourage a cleaner, healthier environment by investing in these technologies and promoting laws that encourage renewable energy markets. This move not only helps to reduce air pollutants but also reduces the environmental impact of energy generation.

Sustainable Materials

Using sustainable materials is another important strategy for lowering pollution at the source. This requires selecting renewable materials that have low environmental effects during manufacture and are recyclable or biodegradable. For example, choosing bamboo or recycled materials over virgin plastic lessens the environmental impact of manufacturing processes and the volume of waste and pollutants produced. Furthermore, implementing circular economy principles in which materials are reused and recycled indefinitely can significantly reduce waste and emissions related to material extraction, manufacture, and disposal.

Implementing Air Filtration Systems

Industrial air filtration systems improve air quality by filtering airstreams in or out of a facility. Whatever the contaminant particulate, odour, VOCs, nitrogen oxides, sulfur dioxide, oil mists, or metal fumes. Air filtration systems in industrial environments are an important part of industrial manufacturing for various reasons, including improving air quality and reducing environmental impact, improving plant worker health and safety, and ensuring proper equipment and machinery operation. Whether tackling the release of pollutants from a towering system or maintaining the quality of an interior plant environment.

Dust & Fume Collection Systems

Dust and fume collection systems are critical in many sectors, including procedures that include exhaust fumes from welding, sanding, grinding, and spraying. A dust collecting system removes particle contaminants from the air in manufacturing facilities, workshops, and industrial complexes. The device cleans the air by passing it through an array of sealed filters. Once the air has been cleaned, it is either released outdoors or recirculated after meeting the required emission limits.

As environmental concerns have developed, dust collection devices have become essential for companies that generate huge amounts of dust particles and ambient gasses. Manufacturers of dust collecting systems must comply with tight government criteria and ensure their customers of the efficiency of their systems as well as compliance with EPA, NFPA, and MSHA standards.

Industrial Air Filtration

Air quality is an important factor in many industrial applications. These applications require good air quality to maintain product integrity, reduce pollution, and maximize product safety. Manufacturers achieve this high air quality by introducing air filtration devices into their production operations. Industrial air cleaning eliminates solid particles and molecular pollutants from industrial operations, improving air quality within a system or environment.

The significant demand for clean and dry compressed air in industries such as pharmaceuticals, research and development, defense, and food processing has led to a growth in the use of industrial air filters. The general working principle of industrial air filters includes the flow of air from the compressor to the dryer and then to the particulate filter, which traps debris, oil, dirt, and other contaminants. Another dryer further dehumidifies the resultant air and sends it to a coalescing filter, eliminating aerosols, oil, and water impurities and continuing to another particulate filter for final air purification.

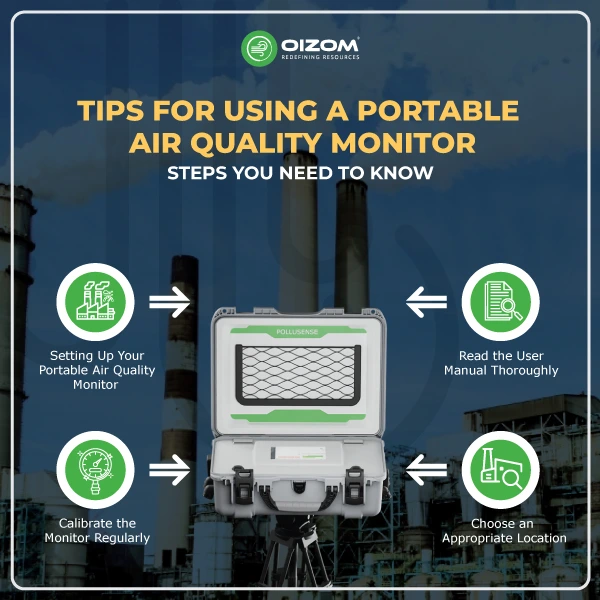

Monitoring Air Quality regularly

You and your coworkers may be so used to poor indoor air quality that you are unaware of the issue unless you seek evidence. Improving air quality in high-emission industrial environments with possibly harmful pollutants is critical for establishing a healthier workplace environment.

- Monitor regulatory compliance: Air quality sensors and other devices allow you to track emissions from industrial sources such as power plants and industries to ensure they satisfy government guidelines. Monitoring Air Quality with Oizom devices such as AQbot, an industrial-grade single parameter with a buzzer feature, on-device display, and memory for six months of in-device data backup, provides real-time data on the Envizom software module. The alarm sounds, ensuring workers’ safety.

AQBot allows industries to tailor their monitoring to what’s crucial for them. Whether it’s Methane (CH4), PM2.5, or any other toxic gas, industries can now invest in monitoring just that specific parameter, thereby making significant savings. But the beauty of AQBot goes beyond just cost savings. It promises real-time, accurate data. Imagine a sudden surge in Carbon Monoxide (CO) levels in an industrial site. With AQBot, there’s no lag, and industries will receive immediate alerts, enabling them to act promptly and ensure safety.

Conclusion

Finally, Controlling the dust generated by manufacturing operations is essential for maintaining appropriate IAQ. A deeper understanding of how factories cause air pollution highlights the importance of adopting sustainable practices to reduce emissions. Additionally, the Device Measures Air Quality Outdoors, providing a comprehensive approach to monitoring and improving both indoor and outdoor air quality. Implementing and maintaining effective methods and equipment appropriate for your industry can improve air quality and working conditions for all parties concerned.

Moreover, let me share with you a fact:

Next, you may protect yourself from factories causing air pollution by monitoring it regularly with oizom devices, which provide real-time and accurate data on the air quality. With this information, you can determine whether or not specific safety precautions, such as breathing masks and PPE, are necessary. With this knowledge, you can live a healthy life with a reduced risk from industrial air pollution.

Factories release pollutants like particulate matter and sulfur dioxide, degrading air quality and harming health and the environment.

To reduce factory pollution, we can use cleaner technologies, install pollution control devices, ensure regulatory compliance, improve energy efficiency, and invest in R&D.

The amount varies by industry and technology used. Factories significantly contribute to global emissions of pollutants like sulfur dioxide and particulate matter.