10 Key Takeaway Points:

- Data-Driven Decisions: Analyzing dust emissions with real-time data allows industries to identify issues early and take corrective action before they escalate.

- Diverse Data Sources: Dust monitoring systems use sensors like OPCs, BAMs, and Gravimetric Dust Samplers to capture accurate real-time dust concentration data.

- Real-Time Monitoring: Unlike manual methods, sensor technology provides continuous, real-time dust monitoring, helping industries meet regulatory requirements.

- Data Cleansing for Accuracy: Cleaning and processing data ensures reliable insights, minimizing errors caused by sensor faults or environmental factors.

- Handling Missing Data: Oizom’s Dustroid stores up to 90 days of data, ensuring accuracy and continuity, even during power or transmission failures.

- Integrated Data Analysis: Combining data from multiple sensors and historical records offers a comprehensive view of air quality trends and patterns.

- Time-Series & Trend Analysis: Historical and time-series analysis helps detect long-term patterns and seasonal variations, providing insights for future planning.

- Predictive Insights: Through machine learning and forecasting models, predictive analysis helps anticipate dust level spikes and proactively address potential air quality issues.

- Machine Learning Advantage: Using AI and machine learning enables smarter air quality management, leading to more precise mitigation strategies.

- Impact on Health and Compliance: Data analysis helps industries comply with environmental regulations and protect public health by identifying pollution hotspots and reducing harmful dust particulates.

Why Data Analysis Matters in Dust Monitoring? Read More to Learn

Data is everywhere! With humans and our machines generating more real-time data than ever, it’s no surprise. Whether it’s through our mobile devices, industrial equipment, or business systems, we’re constantly creating more and more data.

However, in this blog, we will discuss data analysis in dust monitoring systems. Using data analytics to understand your factory’s dust emission is similar to having a smart devices or tool to make smarter decisions. It allows you to analyze Particulate matter data and identify patterns and trends. This way, you can quickly spot any issues with the dust and take action before things get worse.

Data Sources

In a dust monitoring system, the data source refers to the sensors and devices that detect and measure airborne particulate matter, such as PM1, PM2.5, PM10, and PM100. These sensors collect real-time data on dust concentrations in the air. Common data sources in such systems include:

- Optical Particle Counters (OPCs)

- Beta Attenuation Monitors (BAMs)

- Gravimetric Dust Samplers

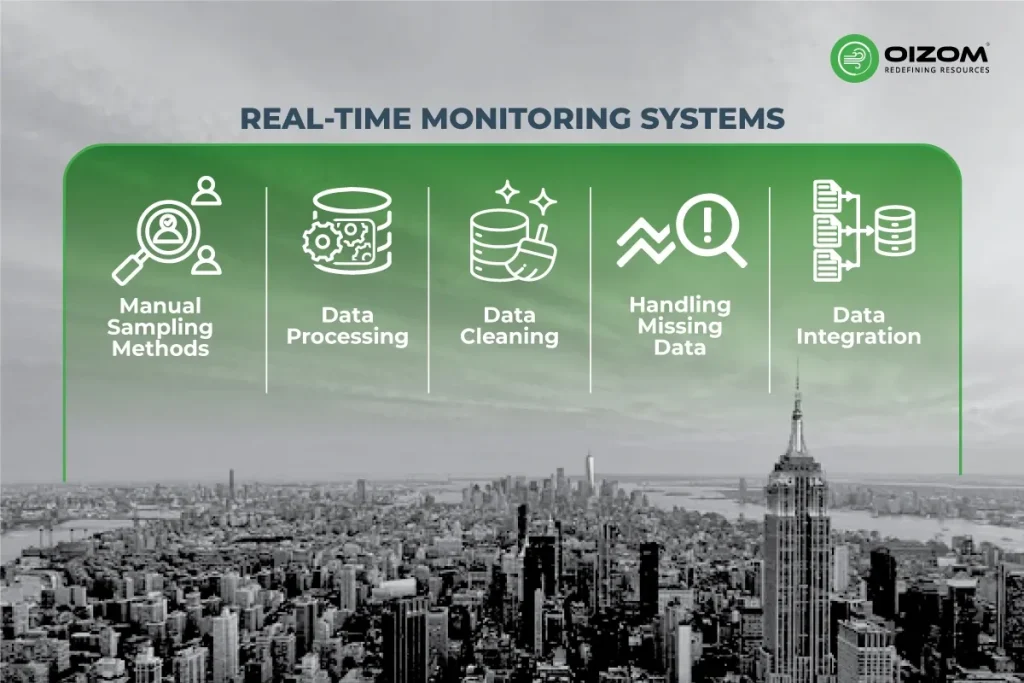

Real-time Monitoring Systems

Dust emissions can have significant environmental and health consequences. To prevent these consequences while adhering to tight regulatory requirements, dust emissions must be continuously monitored and managed. Real-time dust monitoring offers a comprehensive solution.

Manual Sampling Methods

The gravimetric sampling method was the best way to measure the dust in manual sampling methods. Below, we will discuss how it is measured.

- Gravimetric sampling measures the amount of dust collected on a filter, either by allowing dust to settle naturally or by using a pump to draw large volumes of air across the filter. In both cases, the filters are sent to a laboratory for analysis, where the dust concentration for the sample period is determined.

- While these monitor measurements are highly accurate, they only offer historical data, typically covering a period of 24 hours or up to a month. To obtain real-time dust concentration data, sensor technology is essential.

Data Processing

The data processing unit, which consists of the collection host, is the core of the dust monitoring system. It collects and stores the data monitored by the sensor. Then, it performs analysis and processing according to statistical criteria, uploads the processed data to the cloud platform, and manages the localized display of parameters to achieve a combination of environmental parameters and video surveillance images.

Data Cleaning

Data cleansing is an important step in dust monitoring systems to ensure the correctness and dependability of the gathered data. It involves detecting and correcting errors, inconsistencies, or abnormalities caused by various factors, including sensor faults, ambient conditions, or data transmission challenges.

Handling Missing Data

Missing data can be a real headache in dust monitoring systems, often caused by sensor malfunctions, power outages, or transmission glitches. However, tackling these gaps is essential to keeping the system accurate and reliable. So, how can we stay on top of it?

If you’re tired of dealing with the hassle of missing data, relax. Oizom’s Dustroid has you covered! With its internal data storage of 8GB memory, Dustroid can store up to 90 days of data, ensuring you don’t lose a thing. Plus, it’s designed for accuracy. The monitors are placed alongside a custom-built reference station, including a Beta Attenuation Monitor (BAM), which uses U.S. EPA-designated Federal Equivalent Method (FEM) calibration for 72 hours to guarantee top-notch data quality. And the best part? Dustroid runs on solar power, delivering continuous, accurate data no matter the conditions. So, say goodbye to data interruptions!

Data Integration

Data integration is a critical component of dust monitoring systems because it allows for collecting, processing, and analyzing data from several sources, resulting in a comprehensive understanding of air quality.

Combining Data from Multiple Sensors

Combining data from various sensors is an important step in dust monitoring systems for obtaining a comprehensive and accurate picture of air quality. This procedure requires gathering and evaluating data from various sources to create a comprehensive picture of dust distribution and trends.

Integrating Historical Data

Integrating historical data into dust monitoring systems adds context to current observations and helps identify long-term patterns. By merging real-time data with historical records, companies can better know dust patterns, identify potential causes, and design more effective mitigation plans.

Data Analysis Techniques

The data acquired by the dust monitor is analyzed, processed, and displayed in real time. Users can often access this information via a user interface, including numerical statistics, graphical representations, and alerts that sound when dust levels exceed specified limits.

Trend Analysis

Historical data enables the identification of seasonal variations, long-term trends, and recurring dust-level patterns. This information can help to anticipate future trends and plan accordingly.

Time-Series Analysis

Time-series analysis is a statistical technique for analyzing data points accumulated over time. It is especially useful for analyzing trends and patterns in time-varying data sets and anticipating future values.

Seasonal Variations

These are recurring data patterns that appear regularly, usually once a year. Factors that can alter these trends in the context of dust monitoring include:

- Seasonal variations in temperature, humidity, wind patterns, and precipitation can all have a substantial impact on dust levels. For example, dry seasons with strong winds may result in higher dust emissions.

- Human activities: Seasonal variations in agricultural operations, construction activities, and transportation patterns can all contribute to changes in dust levels.

Predictive Analysis

Historical data can be utilized to create prediction models that project future dust levels using historical trends and patterns. These models can assist companies in anticipating possible air quality issues and taking proactive steps to address them.

Forecasting Models

Forecasting models are critical tools in dust monitoring systems because they allow for the prediction of future dust levels based on past data and present conditions. These models can assist organizations in predicting air quality issues, developing mitigation methods, and protecting public health.

Machine Learning Techniques

Machine learning approaches provide effective tools for assessing and forecasting dust levels in monitoring systems. Using these strategies, enterprises can gather useful insights, improve air quality management, and protect public health.

Conclusion

In conclusion, data analysis in dust monitoring plays a pivotal role in ensuring healthier environments by providing actionable insights. AI, machine learning, and the growth of IoT platforms all point to a data-centric future in which sensor data analytics will become an indispensable business practice. By consistently tracking dust levels, we can identify pollution hotspots, assess long-term trends, and implement targeted measures to reduce harmful particulates. This helps industries stay compliant with environmental regulations and protects ecosystems and public health.

With advanced sensors and real-time data, dust monitoring enables swift action to mitigate risks, whether for safeguarding air quality near construction sites, mining areas, or industrial zones. Leveraging this data-driven approach is essential for better understanding and mitigating the impact of dust on our health and environment.