Summary of Blog

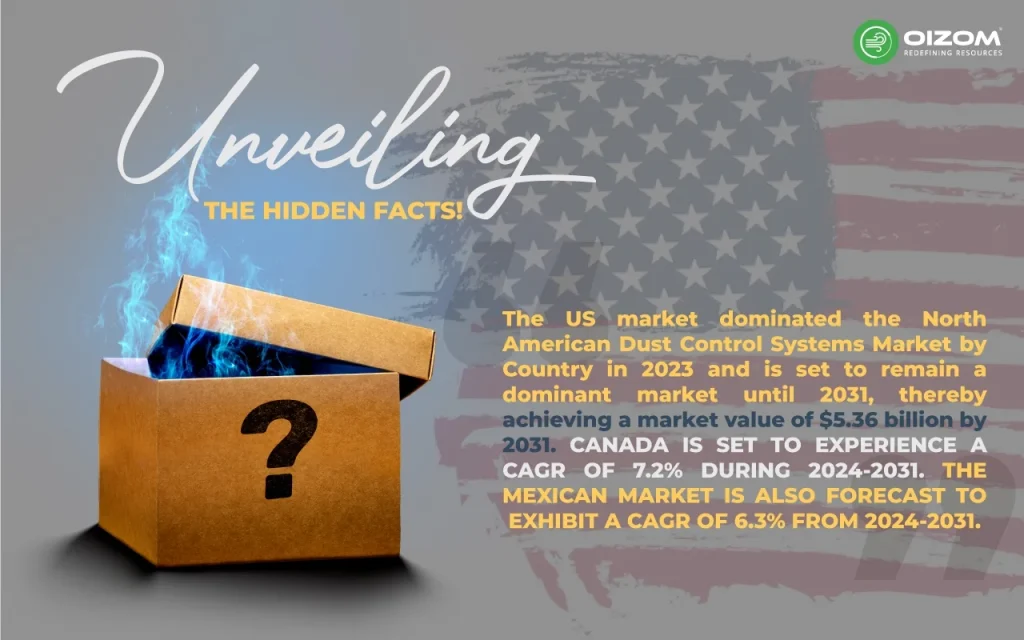

This blog explores the transformative power of AI-powered dust control systems across various industries, from construction sites to mining operations and manufacturing facilities. These innovative systems leverage real-time data collection, AI analysis, and predictive modeling to suppress dust emissions and enhance environmental sustainability effectively. AI optimizes dust control efforts by adjusting ventilation systems, activating water spray systems, and directing mobile dust suppression units while reducing operational costs and ensuring regulatory compliance. With the global dust control systems market projected to soar, embracing AI technologies like Oizom’s dustroids can revolutionize how businesses manage dust, safeguarding worker health and maintaining operational efficiency in the face of airborne particulate challenges.

AI-powered dust control systems

Trying to keep dust out of the air is courageous and hard work. Unfortunately, this is a hard-fought battle. In most cases, dust will be created and released into the atmosphere upon disruption. The demolition business generates large amounts of dust during the destruction of structures for which preventive measures are ineffective, and many other industries suffer from dust-releasing operations.

Let me give you some basic information about dust. It may be everywhere in business, from construction sites to manufacturing plants with vibrating machinery and even in quiet office settings where paper and machines reside together. Dust particles, which range in size from microscopic to visible to the naked eye, are generated by various processes. Stacking components, carving wood, and molding plastic all contribute to the particulate air that characterizes our work environments. Additionally, innovations like Smart Dust Devices are transforming how we monitor and manage air quality in such environments.

Today, I will take you on the journey of how an AI-powered dust control system works and various applications of AI-powered dust control systems. So, let’s get started.

How do they work?

Dust control on industrial and construction sites is critical to modern commercial operations. Fortunately, numerous novel approaches, some more effective than others, exist to contain dust once it becomes airborne. And, no, a fire hose is not among them.

Data Collection

AI-powered dust control systems begin by collecting real-time data from a network of smart sensors and monitoring devices strategically located around the site. These sensors assess various data, including particulate matter levels, weather conditions, air quality indices, and other important environmental elements.

AI Analysis

Once the data has been collected, powerful artificial intelligence algorithms are applied. These algorithms examine the collected data to discover patterns, trends, and likely sources of dust emissions. AI can quickly identify changes in environmental conditions and assess their impact on dust levels since it processes massive volumes of data in real-time.

Predictive Modeling

AI-powered systems can use past data and ongoing studies to build predictive models for future dust emissions. These models allow for proactive decision-making by predicting possible dust hotspots and emission events. By proactively addressing these issues, the system can successfully reduce dust emissions and their environmental impact.

Automated Control

AI-powered dust management systems use insights from data analysis and predictive modeling to change control measures in real-time. This automation enables rapid and precise responses to changing environmental circumstances, increasing the efficacy of dust suppression operations while reducing the need for physical intervention. Whether changing ventilation systems, activating water spray systems, or deploying mobile dust suppression units, automated control ensures that dust control methods are effective and targeted.

Adjusting Ventilation Systems

Ventilation systems are critical for ensuring air quality in places like manufacturing buildings and warehouses. AI-powered dust management systems may dynamically change ventilation systems in response to real-time data analysis.

Ventilation operates on the principle of air exchange to remove enclosed spaces of particulate matter and maintain a dust-free atmosphere.

Types of Ventilation Systems

The choice of ventilation system is critical to its success:

- Natural Ventilation: This leverages the power of nature, using breezes and thermal currents to cycle air within a space. It’s most effective in areas where the natural flow of air can be harnessed.

Mechanical Ventilation: Mechanical systems employ fans or blowers, offering a more controllable and consistently effective solution to dust control across various environments.

Activating Water Spray Systems

AI-powered dust management systems can automatically trigger these water spray systems in reaction to high dust concentrations. The system can precisely target areas with high dust concentrations by combining real-time sensor data with AI algorithms, effectively reducing dust emissions. Using advanced sensors and data analytics, dustroid can accurately measure dust particle concentrations in the air. This real-time monitoring allows for timely and effective responses to dust pollution. Oizom’s data can prompt immediate mitigation measures such as water spraying or adjusting work schedules to reduce dust emissions. The automated activation reduces manual intervention and provides timely dust control actions, improving operating efficiency.

Water can reduce dust in various ways; sprinkler systems can spread a moisturizing net over large regions, such as construction sites, while water trucks give targeted moisture to smaller areas. Drip irrigation systems provide accurate water application in arid places where conservation is critical, ensuring that every drop serves the objective of dust suppression without waste.

Directing Mobile Dust Suppression Units

Mobile dust suppression systems are used in large-scale operations like quarries and recycling factories to control localized dust emissions. AI-powered systems may automatically send these mobile units to specific places with high dust levels. By evaluating real-time data and prediction models, the system can detect hotspots and direct the deployment of mobile dust suppression devices. This focused approach guarantees that resources are used efficiently, increasing the effectiveness of dust control operations while lowering operational expenses.

Applications of AI-powered dust control systems

Dust suppression systems are a requirement for many industries. Some of them are mentioned below.

Construction Sites

Construction and demolition zones are infamous for high amounts of airborne dust, and most construction sites have severe levels of air pollution. Airborne dust particles make it difficult to operate construction equipment properly, let alone breathe, whether your work location is confined to a small space or spreads across a wide area. AI-powered dust control systems offer everything from adjusting water spray systems to controlling ventilation. AI optimizes dust control efforts, ensuring compliance with environmental regulations.

Mining Operations

Mining is undoubtedly a risky business. Active mines are known to cause health problems in personnel exposed to high levels of airborne mine dust over extended periods. AI-powered dust control technologies transform dust management in mining operations by offering intelligent solutions to reduce dust emissions. By dynamically changing control measures based on real-time data, such as activating water spray systems or directing mobile dust suppression units, these systems ensure efficient dust control while minimizing operational disturbances.

Oizom has installed a dustroid to monitor dust in one of the largest coal mines in the world. This helps them monitor air quality alerts and make informed decisions about keeping workers safe.

Manufacturing Facilities

Manufacturing dust is hazardous to your workers, company reputation, and revenue. Dust control in industry means saving lives and livelihoods. Exposure to manufacturing dust causes a variety of respiratory illnesses. Often, there is no solution for severe lung ailments, which might kill your employees.

Cutting, grinding, and material handling are all examples of airborne particle-generating activities in manufacturing plants. AI-powered dust control systems improve air quality in these facilities by continuously monitoring environmental conditions and modifying ventilation systems accordingly. Combining AI algorithms with sensor data allows these systems to maintain ideal airflow and avoid dust particle collection.

Quarries and Recycling Plants

Activities such as blasting, crushing, and filtering at quarries and recycling factories produce considerable amounts of dust. AI-powered dust control solutions help manage dust in these situations by deploying targeted suppression measures. These systems detect increased dust levels in real-time and activate appropriate control measures, such as water spray systems or mobile dust suppression units. By reducing dust emissions at the source, AI-powered technologies enhance environmental sustainability and regulatory compliance, improving the overall operating efficiency of quarries and recycling facilities.

Conclusion

Finally, AI-powered dust control systems are critical for businesses aiming to maintain air quality, assure health and safety compliance, and demonstrate that ‘prevention is better than cure,’ creating a sustainable operational environment. However, AI-powered dust control systems can work well with monitoring devices such as dustroids dust monitoring system , which provide real-time accurate data, help monitor various particulate matter, and make informed decisions about keeping workers safe. Moreover, they can utilize various AI technologies to manage dust.