Aetreum RMC Plant Installed Oizom AQBot PM for Better Air Quality Compliance

Aetreum RMC Plant in Gujarat takes a proactive approach to air quality monitoring with Oizom AQBot PM devices, achieving regulatory compliance and optimizing operational safety.

Gujarat, India

March 2024

Industrial EHS

Aetreum RMC Plant

AQBot PM

Industrial Particulate Monitoring

Gujarat, India

March 2024

Industrial EHS

Aetreum RMC Plant

AQBot PM

Industrial Particulate Monitoring

Introduction: Aetreum’s Commitment to Environmental Responsibility

Aetreum RMC Plant, located in Maljipada on the Gujarat Highway, has taken a proactive step towards responsible operations by integrating continuous air quality monitoring. In light of growing environmental regulations and community concerns, the plant aimed to meet air quality compliance without compromising efficiency.

Aetreum installed three units of Oizom’s AQBot PM devices to meet Maharashtra Pollution Control Board (MPCB) guidelines for Ready-Mix Concrete (RMC) plants. The move not only helped avoid shutdown risks but also reinforced Aetreum’s dedication to sustainable practices. With real-time dust monitoring and IoT-enabled data access, the solution aligned with the plant’s vision of efficient and compliant operations.

Challenges: Urgent Compliance and Operational Risks

Before the installation, Aetreum faced mounting pressure to align with MPCB directives, especially regarding particulate matter emissions. The lack of a monitoring system posed a risk of non-compliance, possible shutdowns, and reduced operational transparency.

To address the gaps, the following challenges needed attention:

- Regulatory Compliance: Aetreum had received a notice from MPCB mandating continuous air quality monitoring for particulate matter.

- Dust Emission Control: High levels of dust from RMC operations risked breaching PM limits and affecting both workers and nearby communities.

- No Real-time Data: The plant lacked visibility into PM levels during peak hours, making it difficult to take preventive action.

- Risk of Penalties: Without a monitoring solution, the risk of regulatory enforcement and penalties was high.

- Data Accessibility: Manual sampling lacked consistency and did not provide actionable data for operational decisions.

- Worker Safety Concerns: Unchecked dust exposure raised concerns about health risks and safety compliance within the plant.

These issues demanded a smart, reliable, and regulatory-ready air quality monitoring solution.

Solution: Continuous Monitoring with Oizom’s AQBot PM

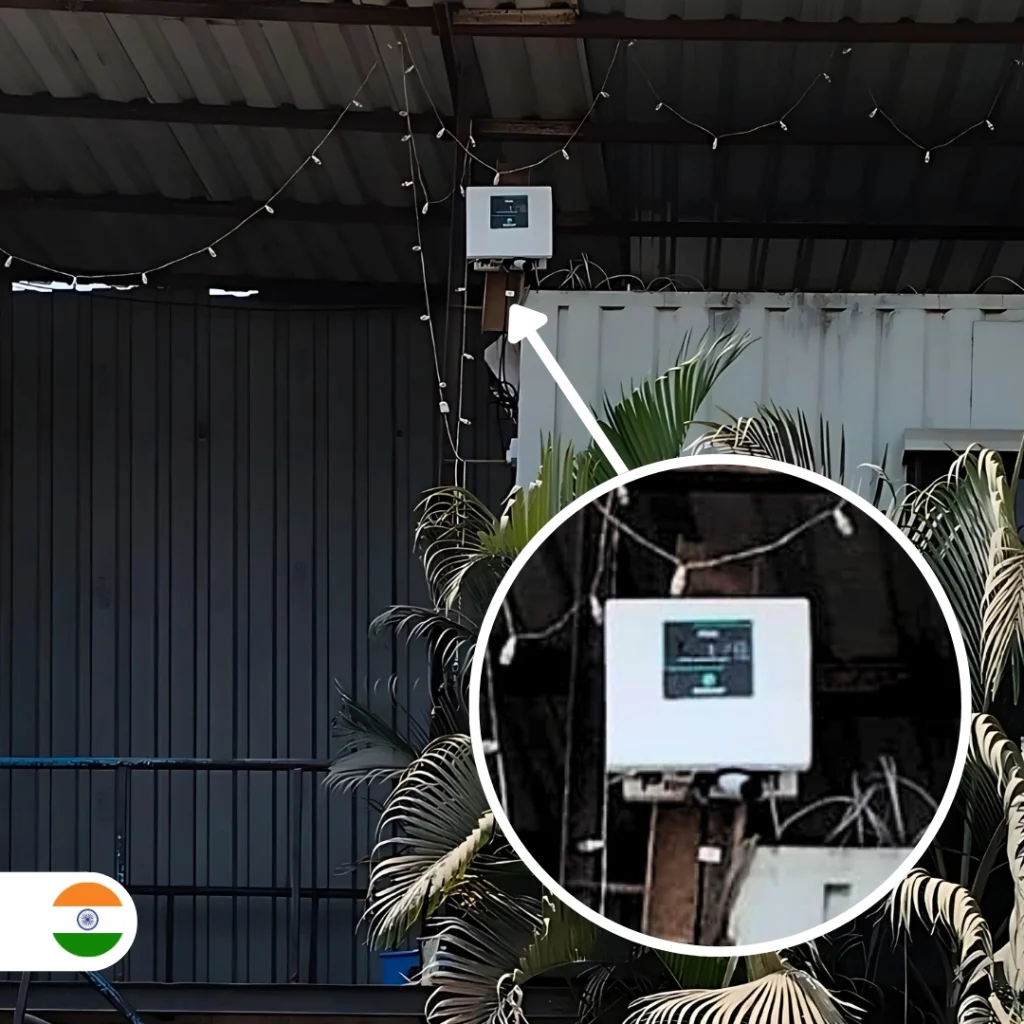

To counter the above challenges, Aetreum selected Oizom’s AQBot PM, a robust air quality monitoring device tailored for particulate matter. Three units were strategically deployed across the site to ensure comprehensive coverage.

The key reasons and features behind the solution include:

- IP66-Rated Design for Dusty Environments: The rugged enclosure made AQBot ideal for outdoor and high-dust areas around the RMC plant.

- Continuous Monitoring of Particulate Matter: The devices provided uninterrupted data on all major particulate matter categories, ensuring regulatory visibility.

- Automated Alerts and Historical Trends: The plant team received alerts when PM levels crossed thresholds, allowing them to adjust processes or enhance dust control mechanisms.

- User-Friendly Dashboard: The simplicity of the software made it easy for both environmental officers and site supervisors to interpret data and use insights for better control.

- Ready for Compliance Reporting: The generated data can be used directly to demonstrate compliance during MPCB inspections.

The combination of robust hardware and easy-to-use software created a seamless solution for both compliance and process optimization.

Transformation: Improved Processes, Clear Visibility

Post-installation, Aetreum experienced tangible improvements across operational and compliance areas. The shift from reactive to proactive air quality control enabled a more confident and efficient approach to day-to-day activities.

Some of the key changes included:

- No Need to Pay Penalties: Real-time compliance reporting helped the plant avoid penalties or fines from the pollution board.

- Seamless Execution of RMC Processes: Teams could operate with better coordination, knowing that air quality was being continuously tracked.

- Real-Time Monitoring and Action: Dust levels could be managed in real-time based on data alerts from Envizom.

- Enhanced Decision-Making: Daily reports and trend analysis helped the operations team plan better work shifts, minimizing dust during peak hours.

- Worker Confidence and Safety: Transparent air quality data improved morale and safety awareness among on-ground staff.

- Data-Driven Maintenance: The team used insights to schedule water spraying and equipment cleaning more effectively, optimizing resource use.

These improvements showcased the real-world value of combining environmental responsibility with smart technology.

Broader Outcome: Strengthening Long-Term Impact

The success of Oizom’s installation didn’t stop at operational efficiency. It laid the groundwork for a longer-term impact:

- Reputation as a Responsible Operator: The move strengthened Aetreum’s brand image among regulatory bodies and nearby communities.

- Scalable Framework for Other Sites: The implementation acts as a benchmark model for similar plants under the same group or region.

- Data for Future Planning: With historical air quality data, Aetreum can forecast trends and plan expansions more responsibly.

Conclusion: Forward-Looking Environmental Leadership

By choosing Oizom’s AQBot PM, Aetreum RMC Plant turned a compliance challenge into a strategic advantage. The installation not only ensured that regulatory requirements were met but also helped streamline operations, improve safety, and build stakeholder trust. Backed by real-time data from Envizom, the plant now operates with higher visibility and reduced risk. This step reflects Aetreum’s broader commitment to cleaner, smarter, and more responsible infrastructure development.

Do you have a specific requirement?

Schedule a call with our expert team and get the right solution

for your project.