Summary

The ceramic industry plays a key role in infrastructure and everyday life. However, its processes, from sourcing raw materials to kiln firing and glazing, considerably contribute to air pollution. Dust, particulate matter, and chemical emissions pose problems not only for worker health but also for environmental quality and regulatory outcomes.

Air quality monitoring systems provide a comprehensive view into this complex industrial ecosystem, offering real-time insights into key pollutants such as PM2.5, PM10, NOx, SOx, VOCs, and heavy metals. Monitoring emissions in real-time enables manufacturers to gain a deeper understanding of pollution sources, refine their manufacturing processes, and maintain safer and cleaner facilities. EHS professionals benefit from the data, which enables air quality management to shift from a reactive task to a proactive one, adopting a data-driven approach and thereby bridging the efficiency-responsibility gap in operations.

How Air Quality Monitoring Boosts Ceramic Manufacturing

The ceramic sector, which manufactures tiles, sanitaryware, porcelain, is crucial to the current infrastructure, but there’s an often-neglected problem: air pollution. Raw material dust, kiln stack emissions, and glazing fumes may impact worker health, environmental quality, and regulatory compliance.

Air quality monitoring systems provide real-time data on pollutants, enabling manufacturers to take proactive measures to manage emissions effectively. For EHS specialists, leveraging this information is crucial to designing safer work environments, minimizing the environmental footprint, and ensuring sustainable development within the ceramic sector.

Why Air Quality Matters In the Ceramic Industry?

The ceramics industry, which encompasses tiles, sanitaryware, porcelain, and other products, significantly contributes to air pollution through high-temperature operations and the handling of raw materials. Maintaining good air quality is essential for the health of workers, as well as for environmental conservation and compliance with regulations.

Why air quality is essential:

Human Health:

Ceramic production emits fine particulate matter (PM2.5 and PM10), silica dust, and kiln fumes. These exposures can lead to respiratory issues, skin irritation, and other health complications for workers and surrounding communities.

Environmental Impact:

Emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and volatile organic compounds (VOCs) from glazes and fuels can also contribute to smog, acid rain, and local air pollution. Effective monitoring and mitigation minimize the environmental impact of the ceramic industry.

Regulatory Compliance and Operational Efficiency

Governments usually impose strict air quality standards on industries. Where noncompliance can result in fines, production shutdowns, or reputational loss. Tracking major pollutants, such as PM, NOx, SOx, and VOCs, enables factories to adjust their processes, switch to cleaner fuels, and efficiently introduce filtration systems.

By understanding and regulating air quality, the ceramic industry can enhance workplace safety, resulting in a reduced environmental footprint and environmentally friendly growth, making it a key element of responsible manufacturing.

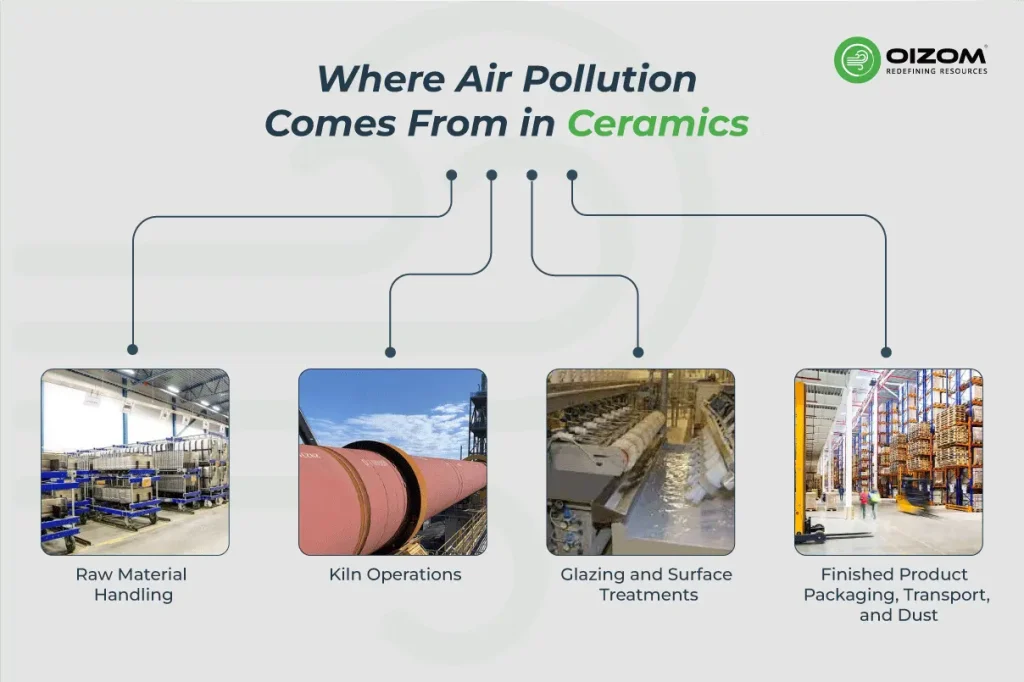

Where Air Pollution Comes From in Ceramics

Air pollution in ceramics is generated during the multi-stage production process, which emits specific pollutants into the air. Knowledge of these sources of pollution is crucial for controlling emissions and improving air quality.

1. Raw Material Handling:

The grinding, crushing, and mixing of clay, feldspar, silica, and other materials releases particulate matter (PM10 and PM2.5) and silica dust into the atmosphere. Fine particles are toxic when inhaled and are among the most ubiquitous pollutants in ceramic workshops.

2. Kiln Operations:

Hot firing of ceramics within kilns emits nitrogen oxides (NOx) and sulfur oxides (SOx), particularly when fossil fuels such as coal, natural gas, or heavy oil are burned. Incomplete combustion can also emit carbon monoxide (CO) and black carbon.

3. Glazing and Surface Treatments:

Using glazes, colors, and coatings can emit volatile organic compounds (VOCs) and heavy metals, such as lead or cadmium, if not handled properly. These compounds help manage smog formation and can have a significant impact on health.

4. Finished Product Packaging, Transport, and Dust:

Even after firing, dust from finished tiles, sanitaryware, and other ceramic products may become airborne during handling, storage, and transportation, contributing to particulate emissions.

By pinpointing these primary sources of raw material dust, kiln emissions, glaze VOCs, and handling dust, ceramic manufacturers can effectively focus their pollution control measures on these points, thereby enhancing workplace safety and reducing their environmental impact.

Are Worker Health and Poor Air Quality Related?

Individuals in the ceramics sector regularly interact with dust, fumes, and chemical releases, making indoor air quality a key factor in maintaining their health. Low indoor air quality can cause temporary irritation and long-term health problems.

1. Respiratory Issues

Fine particulate matter (PM2.5 and PM10) and silica dust from raw materials can penetrate the lungs, causing symptoms such as coughing, wheezing, bronchitis, and long-term conditions like silicosis or chronic obstructive pulmonary disease (COPD).

2. Eye and Skin Irritation:

Dust, VOCs, and heavy metals in glazes can irritate the eyes, skin, and mucous membranes, leading to redness, itching, or dermatitis over time.

3. Systemic Effects and Fatigue:

Exposure to volatile organic compounds (VOCs), nitrogen oxides (NOx), and sulfur oxides (SOx) can lead to headaches, dizziness, and overall fatigue. Continuous exposure might also affect the cardiovascular system and overall health.

4. Increased Occupational Risks:

Declining air quality impairs concentration and energy, indirectly increasing the risk of occupational accidents, particularly in high-heat and machinery-intensive ceramic factories.

By improving air quality through proper ventilation, effective dust management, and emission monitoring, ceramic producers can protect workers’ health, increase efficiency, and ensure compliance with safety legislation.

What Do Air Quality Monitoring Systems Do?

Air quality monitoring systems are crucial in the ceramic industry for measuring and monitoring pollutants in the environment. The systems allow factories to monitor their emissions and take swift action to protect workers, local communities, and the environment.

Primary Functions of Air Quality Monitoring Systems:

Real-Time Measurement of Pollutants:

Monitoring systems track major pollutants, including particulate matter (PM2.5 and PM10), nitrogen oxides (NOx), sulfur oxides (SOx), volatile organic compounds (VOCs), and heavy metals. Real-time data enables factories to detect peaks and take corrective action immediately.

Regulatory Compliance:

By continuously monitoring air quality, these systems aid ceramic manufacturers in complying with government regulations and environmental laws, thereby preventing penalties and ensuring sustainable operations.

Health and Safety Protection:

Continuous monitoring prevents surrounding people and workers from being exposed to higher levels of pollutants. Advisory systems and alarms can trigger preventive actions such as enhanced ventilation or temporary process changes.

Data-Driven Process Optimization:

Air quality data can help identify which segment of the manufacturing process contributes the most to emissions. This information enables manufacturers to adopt cleaner fuels, enhance kiln efficiency, or optimize material handling to minimize overall pollution.

By offering precise, real-time measurements of air quality, these systems enable pollution control to become proactive rather than reactive, promoting cleaner air and a healthier workplace.

Choosing the Right Air Quality System for Your Facility

Selecting a suitable air quality monitoring system is crucial for ceramic plants aiming to create safe working environments, ensure regulatory compliance, and promote environmental sustainability. Although multiple alternatives are available, ambient, sensor-based systems are increasingly favored for their precision, real-time information, and minimal deployment requirements.

Significant Factors to Consider When Choosing a System:

Pollutant Coverage

Make sure the system is capable of measuring the key pollutants in ceramics, including PM2.5, PM10, NOx, SOx, VOCs, and heavy metals. Wide coverage helps develop a clear understanding of the facility’s air quality.

Real-Time Monitoring and Alerts:

Sensor-based systems provide continuous, real-time information, allowing instant action if pollutant levels increase.

Scalability and Flexibility:

Ambient sensor-based monitors can be installed at multiple points, both indoors and outdoors, depending on the facility’s size and layout. They are easy to align with the existing infrastructure and can scale up to meet increasing monitoring needs.

Data-Driven Insights:

Advanced systems often include dashboards and reports that help identify hotspots in emissions, track trends, and optimize processes for improved efficiency. This makes pollution control more data-driven versus reactive.

Through ambient, sensor-based air quality monitoring, ceramic manufacturers can preserve healthier working conditions, minimize emissions, and make data-driven decisions. Solutions like Oizom’s environmental monitoring equipment are designed for such holistic and practical use, eliminating the hassle of conventional manual sampling techniques.

Conclusion

The role of the ceramic industry in air pollution is vital, especially in high-emission areas such as raw material handling, kiln operation, and glaze firing processes. Worker health, environmental quality, and compliance with regulations emphasize the importance of identifying and effectively controlling these emissions.

Air quality monitoring systems redefine how manufacturers perceive and address these issues. Through constant, real-time feedback on key pollutants, they enable pollution control ahead of time, allowing industrial development to proceed in harmony with environmental stewardship. Ultimately, adopting data-centric air quality management is not merely about compliance, but a pledge to a safer environment and a cleaner, greener future.