Summary

Miners work under an atmosphere that is not as simple as it may seem. For example, dust in a mining site is difficult to detect. Another example would be the amount of dangerous gas produced at mining sites. These gases impose extreme pressure on mining equipment, thereby reducing production speed. It also exposes miners to toxic fumes from mining at all times. Multiple risks emerge from the gases produced in mines, which can lead to injuries and death. Through continuous air quality monitoring, the mining industry can ensure a safer, more efficient, and productive work environment.

Key Air Pollutants To Be Monitored in Mining Sites

Pollution appears invisible, but its effects are painfully visible. Mining sites contain numerous airborne hazards that can fluctuate at any minute, yet the story of these pollutants often goes untold. This blog explores air quality in mining, what’s being released, why it matters, and how operators keep it under control. Eventually, this will help understand why managing air isn’t just about safety, but also about smarter operations, informed decisions, and staying ahead of unpredictable risks.

What Makes Mining Sites Pollution-Intensive?

Mining is inherently highly polluting due to the combination of energy-intensive mechanical systems and the exposure of geologic materials, which creates conditions for continuous pollutant generation and dispersion. Core mining activities include drilling, blasting, crushing, screening, and material handling, all of which break rock down into very fine pieces. The process releases large amounts of particulate matter and TSP into the environment. Dusts stay airborne for longer than usual as mining sites are generally dry, barren, and lack adequate vegetation, providing little to no natural barriers for dust containment.

Another factor contributing to the amount of airborne pollutants in mining is diesel-fueled machinery. Haul trucks, excavators, loaders, and generators continuously operate and emit high levels of NO₂, SO₂, CO, and unburned hydrocarbons. Since these machines operate in an open area and are mobile, their exhausts are rapidly dispersed over large areas rather than being contained. Geology also plays a role in the formation of silica, sulfides, heavy metals, and other minerals found in ore deposits. When these materials are disturbed or processed by mining, they release respirable crystalline silica, hydrogen sulfide, mercury vapour, or metal-laden dust, adding toxic pollutants into the air, beyond standard dust and combustion emissions.

Pollution levels in underground mines are affected by poor ventilation, driving rapid accumulation of methane, diesel exhaust, and fine particulate matter in confined areas and increasing the risk of health problems and explosion hazards. Combining these variables creates an environment in which air pollution arises from both everyday mining practices and properties of the materials mined. Therefore, systematic real-time monitoring of mining sites is essential to identify and control potential sources of pollutants, better understand their behavior, and prevent escalation when they are not accounted for.

Priority Pollutants in Mining Environments

Many airborne pollutants are released during mining processes and by diesel machinery. Each type of pollutant reacts differently when released into the air; some cause poor visibility for vehicles and equipment, while others affect ventilation and increase the risk of explosions or downtime for the business. By monitoring these pollutants throughout the day with technology, mining companies can ensure their employees are safe while protecting their operations and complying with local, state, and federal regulations.

Particulate Matter (PM1, PM2.5, PM10 & TSP)

The dust produced by mining activities can quickly cover large areas of mining sites due to the wind. When fine dust particles accumulate in the ventilation system or on machinery, they interfere with airflow, slowing work cycles and machine operations. Real-time monitoring provides a tool to help manage on-site dust by determining when to use suppression techniques.

Respirable Crystalline Silica (RCS)

While drilling and crushing earth, silica is emitted and suspended in the air. Even small fluctuations in RCS levels may put excessive demand on filtration systems and ventilation systems. RCS monitoring enables mines to optimize drill programs and suppress RCS near silica-rich areas using targeted measures.

Gaseous Pollutants

Burning diesel and using explosives releases gases that accumulate near equipment and in poorly ventilated areas. This accumulation harms productivity and necessitates temporary shutdowns. Monitoring enables mines to create fleets with better routing capabilities and develop safer ventilation and blasting procedures.

Methane (CH₄)

Flammable gases like methane can migrate from strata into underground environments. If not appropriately controlled, methane can accumulate and present a significant explosion hazard. Continuous monitoring will ensure that adequate controls are available to prevent the accumulation of methane and subsequently allow safe operation of equipment and electrical systems.

Volatile Organic Compounds (VOCs)

Fuels, solvents, and chemical process emissions can alter the accuracy of monitoring equipment by causing odor and contributing to ozone formation. Correct VOC control measures will improve VOC storage and minimize disruptions in areas sensitive to odors.

Hydrogen Sulfide (H₂S)

H₂S is created through the mining of sulphide ore. As a result, H₂S may accumulate wherever minerals are extracted and, at elevated levels, pose a threat to workers’ breathing. Continuous monitoring will enable the identification of localized H₂S sources and ensure adequate ventilation of working areas.

Heavy Metals in Airborne Dust

Processing and crushing can release metal-laden dust that contaminates surfaces and equipment. Monitoring helps mines detect contamination early, improving dust control and protecting processing quality.

How Mining Operators Should Monitor These Pollutants

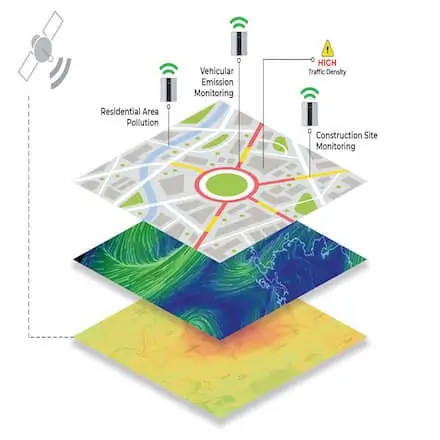

Mining operations require both live and random sampling for comparison, as different additives vary in type and location within the operational environment. Operators usually place live sensors close to areas where dust and gas concentrations are most likely to vary, including drilling, road transport, crushing and haulage, the mine entry, and the area where any fuel used for machine operation is stored. By collecting data from the live sensors, operators can monitor responses, such as increasing the amount of fresh air to the tunnelling area, increasing the number of haul trucks, or turning on the water spray system to reduce dust.

Samples also validate the real-time trends indicated by the live sensors and can assist in the submission of compliance reports. In addition to providing a source of compliance information, effective monitoring also depends on placing monitoring devices in the correct locations. Whereas for underground operations, the use of multi-layer monitoring systems in entry zones, working phases, and return air systems is typical.

The optimal way to use data generated from monitoring is to use it alongside daily operations, triggering safety alerts, optimising ventilation, and planning for hazardous work. The integration of both monitoring methods can provide mining operators with assurance in maintaining work safety, limiting operational disturbances, and achieving regulatory compliance.

Why Real-Time Air Quality Monitoring Is Critical for Mines

Air quality in mines can vary quickly due to changing activity patterns. Therefore, ongoing monitoring is critical to ensure safe working conditions for the workforce and to promptly identify and respond to contaminant levels exceeding safe limits in the mining environment. Continuous monitoring provides operators with ’real-time’ alerts of emerging issues. It facilitates planning higher-risk work during times when air quality is at its best.

For compliance teams, continuous monitoring provides a better understanding of on-site environmental conditions by offering an evidence-based view of air quality. Real-time air quality monitoring provides operators with immediate alerts and trend data. As a result, operators can incorporate air quality information into their daily operational decision-making processes.

Conclusion

Monitoring mining pollutants isn’t merely a regulatory checkbox; it’s a way to make sure operators can understand, anticipate, and control the dynamic environment around them. From dust and gases to flammable concentrations, each pollutant tells a story about operational challenges and opportunities. By integrating real-time data into everyday decisions, mines can protect workers, optimize productivity, and maintain compliance, all while turning complex air-quality challenges into actionable insights.

FAQs

Respirable crystalline silica, methane, toxic gases (NO₂, SO₂, CO), and fine particulate matter pose the highest operational and safety risks.

They use a combination of real-time sensors and periodic sampling to track dust, gases, and flammable concentrations across active zones.

Monitoring requirements vary depending on the type of mine, ore body, equipment used, and whether the site is open-pit or underground.

Monitors should be placed near emission sources, dust pathways, worker-exposed areas, and key ventilation points for accurate data.