Hira Electro Smelters Transforms Air Quality Compliance with Oizom’s Polludrone

To ensure safety, compliance, and operational efficiency, Hira Electro Smelters deployed Oizom’s Polludrone at its ferroalloy plant in Bobbili, transforming environmental management with real-time air quality intelligence.

Vizianagaram, Andhra Pradesh

January 2025

Industrial EHS

L&T Construction

Polludrone

Airport construction site monitoring

Bobbili, Andhra Pradesh, India

May 2025

Industrial EHS

Hira Electro Smelters Limited (HESL)

Polludrone

Real-time Air Quality Monitoring

Introduction: Prioritizing Air Quality in Ferroalloy Manufacturing

As India’s industrial backbone continues to strengthen, balancing production growth with environmental responsibility is more vital than ever. Hira Electro Smelters Limited (HESL), a public limited company and wholly owned subsidiary of Hira Power and Steels Ltd., operates a high-capacity ferroalloy manufacturing facility in Bobbili, Andhra Pradesh. Specializing in the production of ferro manganese and silico manganese, the facility caters to both domestic and global markets with an annual production capacity of 15,000 metric tons.

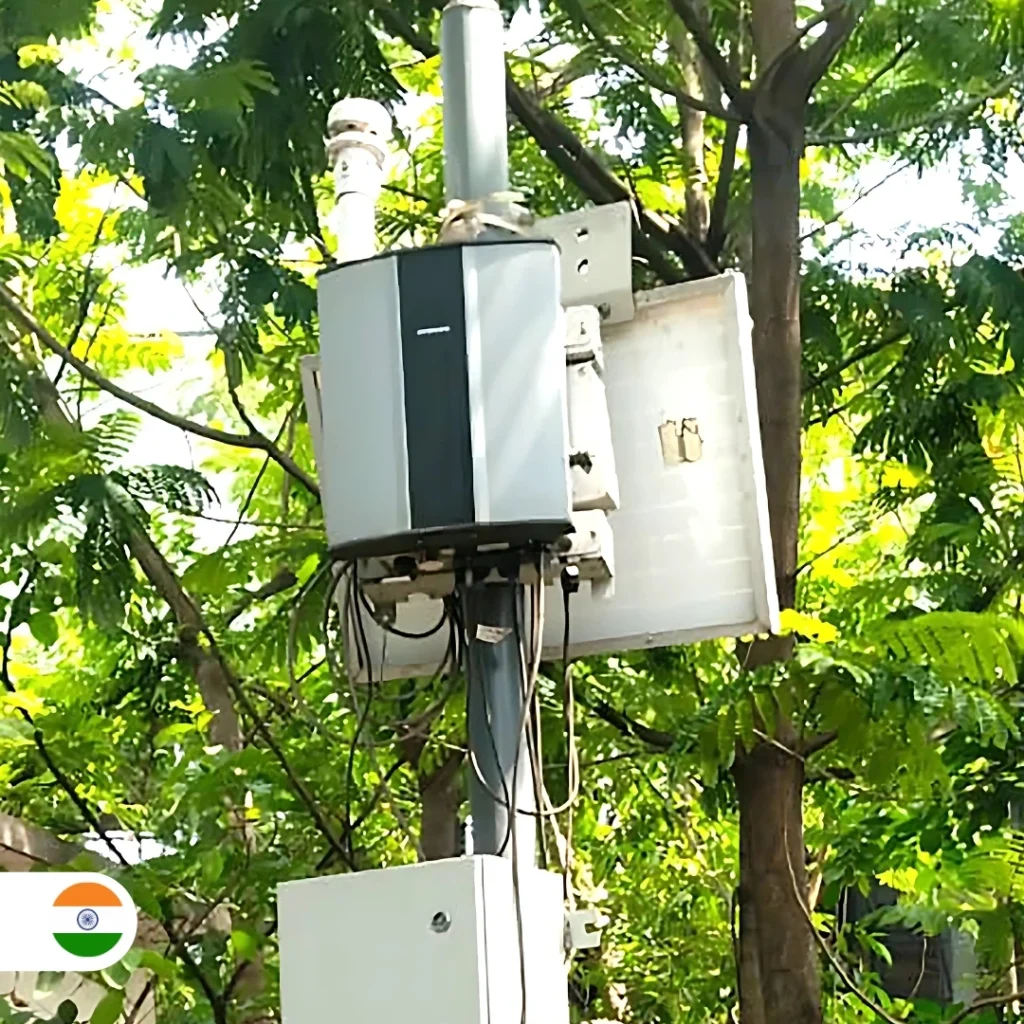

While metallurgical production is essential to support sectors like construction, aerospace, automotive, and energy, it also presents challenges related to air pollution, especially from particulate matter and combustion gases. To ensure compliance with environmental norms, enhance workplace safety, and drive operational efficiency, Hira Electro Smelters partnered with NK Square Solutions and chose Oizom’s Polludrone, a smart, real-time air quality monitoring solution specifically designed for industrial environments.

Challenges: Navigating Air Quality in High-Emission Environments

Operating in the heavy industrial landscape of ferroalloy manufacturing, Hira Electro Smelters faced several critical environmental and operational challenges:

- High Emissions from Operations: Continuous smelting of manganese ores releases significant volumes of particulate matter (PM1, PM2.5, PM10, & PM100), and gaseous pollutants like SO2, CO, NO, and NO2, directly impacting indoor and ambient air quality.

- Lack of Real-time Monitoring: The absence of continuous air quality monitoring made capturing pollutant fluctuations during peak operational hours difficult, limiting the team’s ability to take timely action.

- Worker Health and Safety Concerns: Employees working in proximity to furnace zones and raw material handling areas were at risk of prolonged exposure to airborne pollutants, increasing the likelihood of respiratory ailments and long-term health issues.

- Regulatory Compliance: As a large-scale manufacturer, Hira Electro Smelters is subject to stringent air quality standards enforced by state and national pollution control boards, with growing expectations for digital reporting and transparency.

- Inefficient Environmental Management Practices: Without granular pollutant-level insights, identifying emission sources or optimizing mitigation systems like ventilation or filtration remained challenging.

Recognizing these operational vulnerabilities and with a strong commitment to environmental performance and occupational safety, Hira Electro Smelters decided to adopt a more robust, real-time air quality monitoring approach, laying the foundation for proactive and sustainable industrial operations.

Solution: Real-time Air Quality Intelligence with Oizom’s Polludrone

To address these challenges, Hira Electro Smelters implemented Oizom’s Polludrone, a cutting-edge air quality monitoring system known for its high accuracy and industrial-grade durability.

- Comprehensive Parameter Monitoring: Polludrone was configured to monitor a wide range of pollutants, including particulate matter, and gaseous pollutants like SO2, CO, NO, and NO2, as well as environmental parameters like temperature, humidity, and pressure.

- Industrial-Grade Accuracy: With over 90% data accuracy compared to reference-grade analyzers, Polludrone delivered dependable insights, even in extreme, dust-heavy industrial environments.

- Real-time Alerts: The Envizom allowed the EHS team to set emission thresholds and receive automated alerts during pollutant spikes, enabling rapid response and containment.

- Automated Reporting: Daily and monthly air quality reports were auto-generated through Envizom, ensuring seamless documentation for audits and pollution control board submissions.

- Pollution Dispersion Insights: Wind direction and wind speed monitoring helped identify pollution dispersion paths and potential hotspots within the facility, aiding in strategic mitigation planning.

Hira Electro Smelters chose Oizom’s continuous ambient air quality monitoring system not only to ensure air quality but also to enhance operational efficiency through data-backed decision-making.

Transformation: From Reactive Compliance to Proactive Safety

The implementation of Oizom’s monitoring solution brought measurable and meaningful changes to both operational and environmental aspects of the facility:

- Enhanced Workplace Safety: Continuous monitoring helped create a safer environment by identifying high-risk zones and enabling timely interventions to protect workers from exposure.

- Operational Optimization: Correlating air quality data with furnace operations led to process improvements, better ventilation management, and reduced energy consumption.

- Proactive Emission Control: With real-time alerts, the operations team was able to respond immediately to emission spikes, preventing regulatory violations and mitigating environmental impact.

- Stronger Compliance and Reporting: Automated reports and historical data logs ensured that the plant remained audit-ready at all times, reinforcing adherence to pollution norms.

- Sustainable Growth: With robust environmental monitoring in place, the company set a benchmark for responsible industrial practices, supporting long-term scalability and sustainability.

By integrating Polludrone data with operational workflows, Hira Electro Smelters shifted from reactive environmental management to a proactive, data-driven safety culture.

Broader Outcome: Strengthening ESG and Community Trust

Beyond operational efficiency and compliance, the impact of the installation extended to:

- Regulatory Compliance: Meeting air quality standards became streamlined with automated reports from Envizom, reducing the risk of fines or penalties.

- Stakeholder Confidence: Transparent air quality data showcased Hira’s commitment to sustainability, positively influencing investors and regulators.

- Enhanced ESG Profile: Demonstrating environmental responsibility strengthened Hira Electro Smelters’ standing as a responsible industrial entity in the community.

Conclusion: A Future-Ready Approach to Air Quality and Efficiency

By partnering with NK Square Solutions and deploying Oizom’s Polludrone, Hira Electro Smelters has positioned itself as a forward-thinking manufacturer that values employee safety, regulatory integrity, and environmental stewardship. With the power of real-time air quality monitoring and advanced analytics via Envizom, the plant now operates with greater confidence, compliance, and care for its people and surroundings.

This case stands as a testament to how continuous air quality monitoring not only protects human health but also drives operational excellence in heavy industries.

Do you have a specific requirement?

Schedule a call with our expert team and get the right solution

for your project.