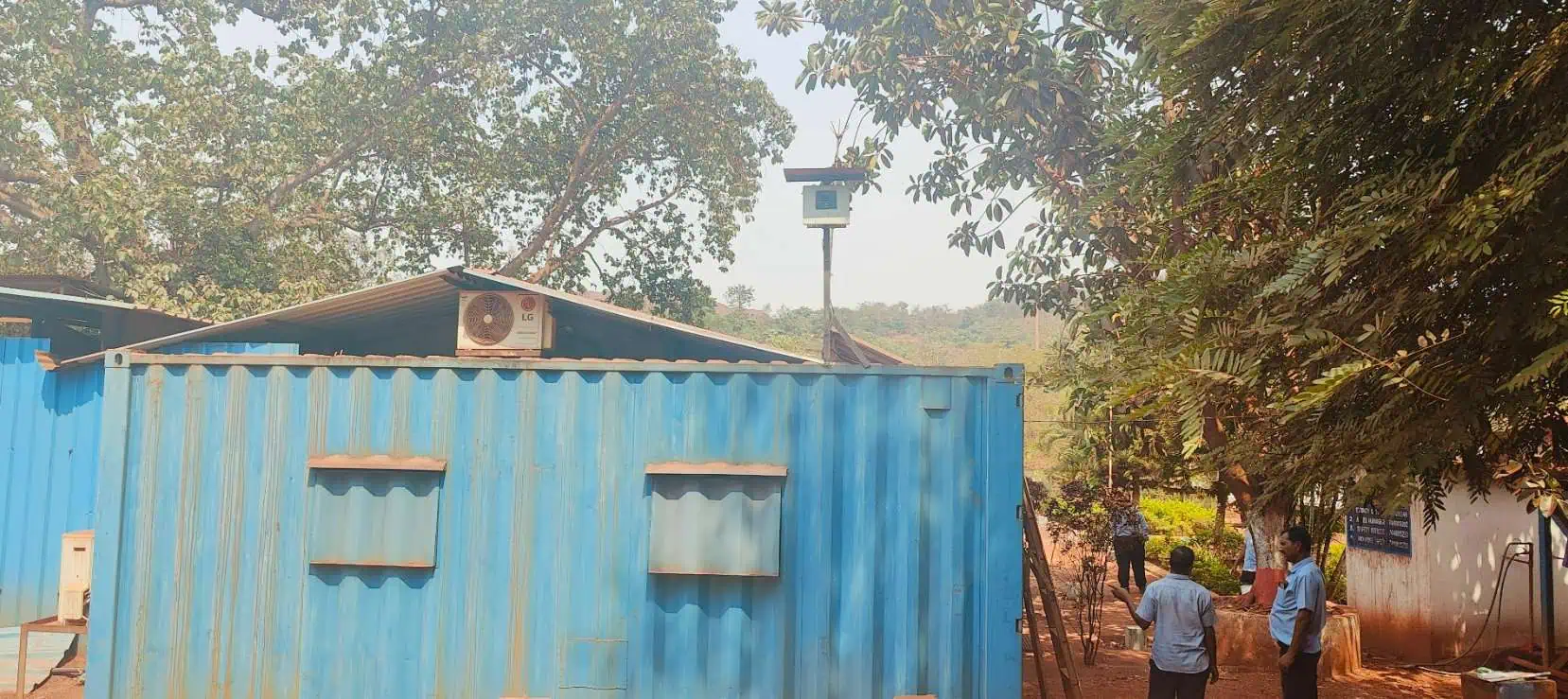

Real-time Noise monitoring at S.N. Mohanty mines

Real-time Noise monitoring at S.N. Mohanty mines

The Mohanty Group, operating in a region known for its mining activities, was likely confronted with issues related to noise pollution from its operations. To address these concerns and ensure compliance with environmental regulations, they chose AQBot Noise, which helped them to take proactive steps to mitigate pollution.

Barbil, India

June 2024

Mining industry

SNM Group

AQBot Noise

Noise Monitoring

Our Client

The Mohanty group has been closely associated with the mining industry in Odisha since the 1940s. Over the years, the Mohanty Group has grown into a diverse conglomerate, initially specializing in iron and manganese ore and later expanding its footprint into manufacturing, power generation, infrastructure, and social development. For the past three decades, the firm has been actively mining iron ore, manganese ore, and bauxite, supplying the metal industries within Odisha and beyond. A prominent entity within this conglomerate, S.N. Mohanty Group, plays a pivotal role in meeting the needs of metal industries across and outside the state. Meanwhile, M/s. M. G. Mohanty has established itself as a key player in iron and manganese ore mining in the mineral-rich Sundergarh district.

The Challenge

The mining industry, while crucial for economic development, often faces significant environmental challenges, including noise pollution. The Mohanty Group, operating in a region known for its mining activities, was likely confronted with issues related to noise pollution from its operations. These challenges posed potential compliance risks with regulatory bodies and impacted the well-being of nearby communities. To address these issues, the company sought a reliable noise monitoring solution capable of accurately measuring noise levels, providing clear data analysis, and assisting in implementing effective noise mitigation strategies.

The Solution

To address these concerns and ensure compliance with environmental regulations, the Mohanty Group chose AQBot Noise. To monitor the data accurately, they required a reliable noise sensor, and the AQBot noise is equipped with an advanced class -2 noise sensor module that provides precise readings. AQBot’s durability and advanced support electronics make it suitable for harsh industrial environments. It also has an on-device display, allowing for immediate monitoring of noise levels.

The Result

With the installation of AQBot Noise on the mining site, the Mohanty Group has addressed the noise pollution challenge and successfully complied with the regulations of the State Pollution Control Board (under sections 15/19 of the EPA, 1986). Its on-device alarm siren and strobe light for maximum safety provide an early warning of high noise levels in the area, enabling workers and site managers to take proactive steps to mitigate noise pollution and prevent future compliance issues.

The Oizom Envizom software proved invaluable in assisting the Mohanty Group with data visualization and analysis. The software enabled them to receive comprehensive noise level reports daily, weekly, and monthly, providing detailed insights into noise levels and facilitating effective monitoring and compliance efforts. With the help of NEMA 4X-approved enclosure AQBot Noise and advanced environment monitoring Envizom software, they have resumed their mining operations and are receiving real-time noise data.

About Oizom

Innovation, reliability, and environmental responsibility define Oizom. With Oizom’s Polludrone system, Godrej & Boyce efficiently detected and managed the threat of HCl emissions, preserving the integrity of its MS sheets, and underscoring Oizom’s expertise in delivering tailored environmental monitoring solutions.

Do you have a specific requirement?

Schedule a call with our expert team and get the right solution

for your project.