Dust suppression is critical in various industries, including mining, construction, and agriculture. It involves multiple strategies to manage and reduce the dust produced by industrial activities, which can harm workers and the environment’s health. Inhaling dust particles can cause respiratory issues like asthma, bronchitis, and other lung disorders. It can also cause eye and skin irritation and, in severe cases, silicosis, a chronic and incurable lung disease caused by silica dust inhalation. Dusty roads are a headache for everyone; the dust results in safety concerns on the roadway due to decreased visibility.

Moreover, Dust can also harm the ecosystem. It can settle on neighbouring flora and limit its ability to photosynthesise, hence impacting plant development and crop yields. Dust can also build in bodies of water, resulting in lower water quality and the potential for harm to aquatic life. Dust is the worst enemy of heavy equipment air filters. The havoc these tiny particles wreak on machinery is well-known. If you’re considering investing in a dust control programme, this guide will lead you through the most prevalent importance of dust suppression active chemistries in dust control products.

The global dust control systems and suppression chemicals market is estimated to reach USD 17927.0 million by 2030 from USD 12800.7 million in 2021, registering a CAGR of 4.3% from 2022 to 2030.

Annually, 2000 tons of dust is released, of which 75% is deposited on the soil and 25% on the ocean; this process affects the energy, water and carbon cycle (Irene Rodrıguez et al. 2009). The highest amount of dust in the atmosphere occurs with the origin of fine-grained particles, which are more prevalent in arid and semiarid regions (Rains Pour 2008).

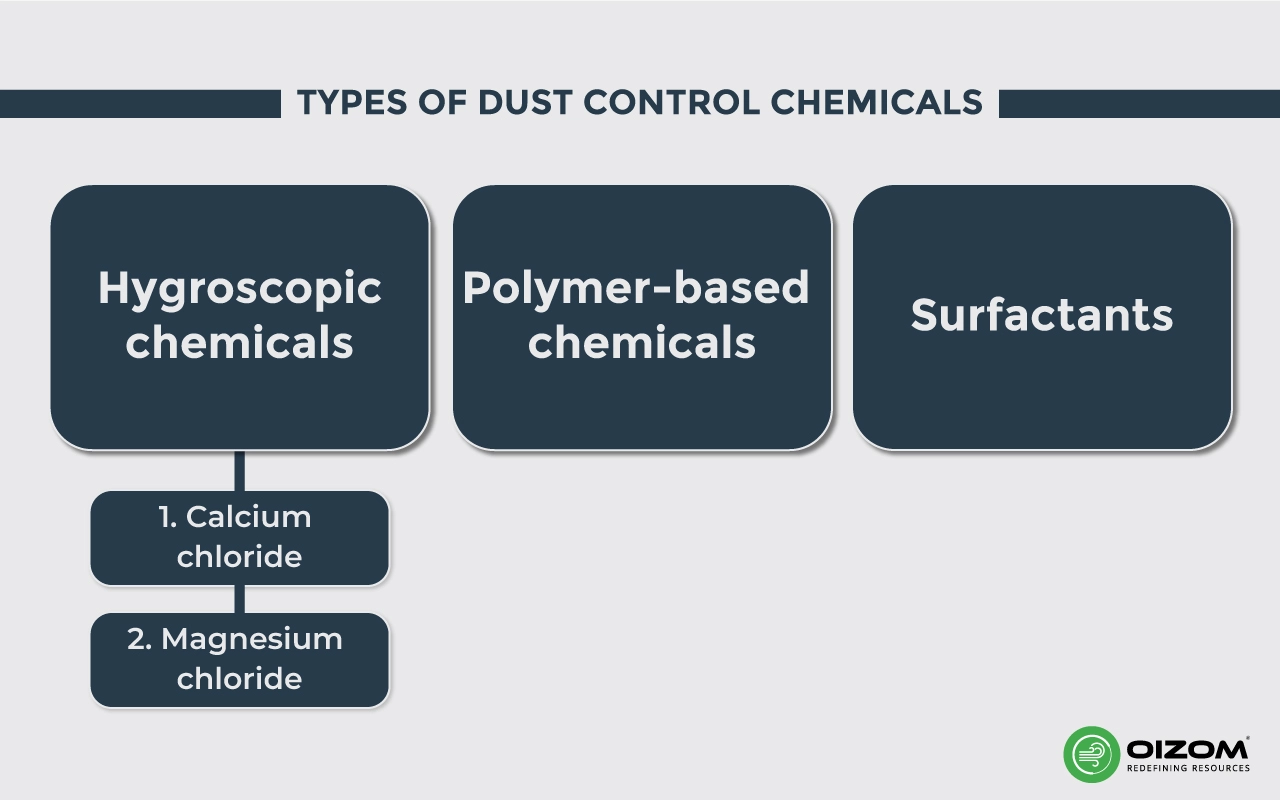

Types of Dust Control Chemicals

Dust suppression strategies vary based on the specific industrial process and the nature of the dust generated. However, this blog will look deeper into more details of dust control chemicals.

Hygroscopic chemicals

1- Calcium chloride is a hygroscopic salt in liquid and flake forms. Calcium chloride collects moisture from the air and surroundings as a hygroscopic dust suppressant. It has a thicker moisture film, higher surface tension, lower vapour pressure, and lower freezing point than ordinary water. Because of this combination, the chemical can keep unpaved surfaces wet and microscopic dust particles in place. This dust suppressant’s average commercial concentration is between 35 and 38%. Calcium chloride remains in liquid form even in dry, high heat.

In 2021, the calcium chloride segment accounted for 29.5% of the global dust control systems and suppression chemicals market. It had the largest market share by chemical type.

2- Magnesium Chloride is another hygroscopic salt that collects moisture from the air and keeps roads moist when applied. This method efficiently reduces the amount of dust particles that escape. Dust control with magnesium chloride is also available in liquid and flake form.

- Magnesium chloride has smaller molecules than calcium chloride. The capacity of both chlorides to regulate dust is due to their chemical composition and the ability of water ions to attach to the metal ions calcium and magnesium. Because magnesium chloride molecules are smaller, the charge between these water-metal ion interactions is dispersed across a smaller surface area, resulting in a more robust electrical field. This means the water ions will not evaporate and remain liquid, keeping the road moist and the dust particles firmly on the surface. As a result, magnesium chloride is a significantly far stronger road stabiliser. Despite this significant difference in chemical composition, magnesium chloride cannot be considered substantially more effective at road stabilisation than calcium chloride, and both dust suppressants are effective.

- Magnesium chloride is one of the most popular dust suppression methods in the Western United States because much of it is locally sourced from the salty waters of the Great Salt Lake in Utah.

Polymer-based chemicals

The primary application of polymer emulsion soil stabilization is frequently described as dust control. Many industry leaders turn to acrylic polymer products for dust control. Dust control is critical in mining and other heavy industries like petroleum refining and oil and gas production. Dust suppression is not limited to roadways; it can also be used on stockpiles, slopes, and commodities in transit. Polymer emulsions are also used in these industries to stabilize transport and access roads to industrial sites.

Polyvinyl acetate and vinyl acrylic derivatives bind or stick to dust particles in synthetic polymer emulsions. Dust suppressants of this type improve clay roads’ tensile strength (cohesiveness or bearing strength) and only need to be treated every few years. Synthetic polymers, on the other hand, degrade in damp and cold circumstances. Some typical synthetic polymer-based dust treatments have lethal dose LD50 and lethal concentration LC50 values ranging from moderately hazardous (50-500 mg/kg) to mildly toxic (> 500 mg/kg). Again, as with any chemical, the Material Safety Data Sheet (MSDS) should be read before application to avoid personal injury. In broad terms, polymers can provide roughly 9 to 18 months of service life when the treated area remains free of disruption and traffic movement.

Surfactants

Dust suppression is a complicated process that necessitates the use of surfactants. Many materials are hydrophobic (dislike water) and tend to resist water from the surface. To reduce the surface’s hydrophobicity, The surfactant further forms a microscopic liquid film to increase the adhesion of dust particles to the material’s character, which additionally prevents their regeneration. Surfactants also significantly reduce the water needed for suppressing dust.

Factors to Consider When Choosing a Dust Control Chemical

Consider these points when exploring the benefits of dust suppression chemicals.

What Is the Location Of Your Project?

When choosing a dust suppression solution, you must consider the weather and climate of your construction project. Dry areas, for example, may necessitate more dust suppression agents due to a lack of moisture in the air. Before deciding on a product, examine what dust suppression compounds have proven successful in your area.

Which Category of Chemical Is Best For You?

For decades, chemical dust control has been utilized to help reduce dust. Investigate all available dust control strategies before selecting a dust suppression chemical. There are four types of dust suppression chemicals.

- Water sprays with surfactant – This method uses surface-active materials to lower the surface tension of the water.

- Foam – Foam improves the wetting efficiency of the surface.

- Water sprays with binders, humectants, and surfactants – This method uses a binder that helps create a barrier of dust suppression on the surface of the soil and enhances moisture.

- Emulsions – Emulsions of surfactants and water suspend binders to create a residual-effect suppressant.

The Environmental Impact Of A Product

- It is preferable to use environmentally friendly dust suppression chemicals. Dust control solutions may travel off the roadway and into nearby bodies of water after application. Use environmentally safe dust suppressants and apply them correctly to avoid contaminating water bodies, including surface and groundwater.

Regulatory Compliance

- The EPA (Environment Protection Agency), OSHA (Occupational Safety and Health Administration), and MSHA (Mine Safety & Health Administration) all issue standards and establish tight requirements for dust control. Regional rules may differ and necessitate your organization select one dust suppression chemical product over another to comply. Before choosing a dust suppression product, review all applicable legislation regarding dust dangers.

Asia Pacific dominated the dust control systems and suppression chemicals market and accounted for the largest revenue share of 47.9% in 2021. The region is projected to observe the fastest growth in terms of revenue during the forecast period.

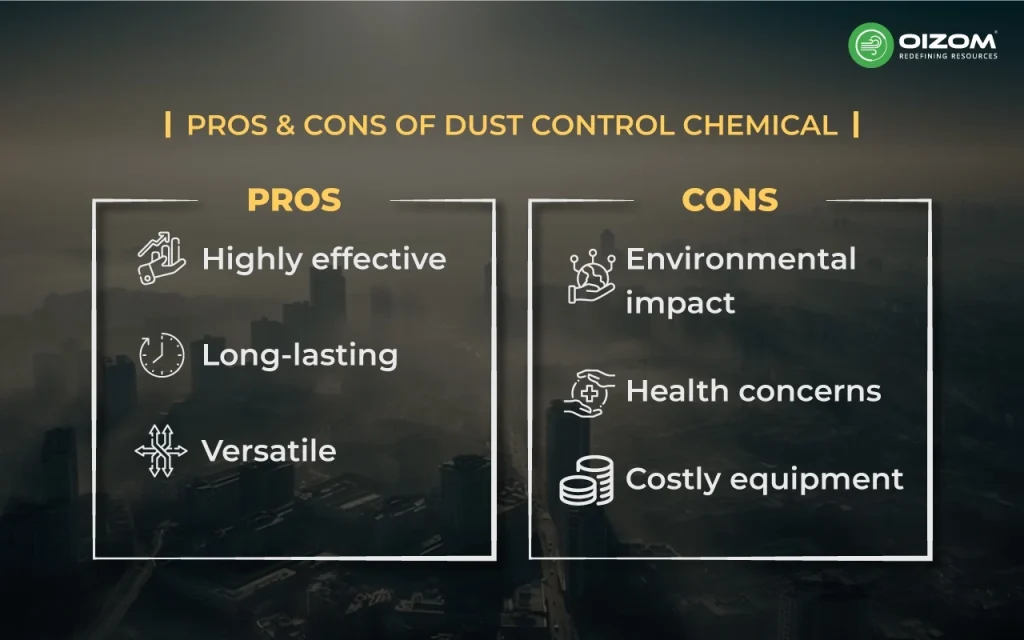

Pros and cons of dust control chemical

Dust control chemicals provide a rapid and effective option for dust management but also have certain drawbacks. Here’s a rundown of the advantages and disadvantages to help you determine if they’re right for you:

Pros:

- Highly effective: Dust control chemicals can dramatically reduce dust particles, improving visibility and air quality.

- Long-lasting: Some chemicals offer extended dust control, requiring less frequent application than water.

- Versatile: Different chemicals are available for various surfaces and applications, from unpaved roads to construction sites to agricultural fields.

Cons:

- Environmental impact: Some chemicals can harm plants, animals, and water quality if improper or carefully chosen.

- Health concerns: Certain chemicals may pose respiratory or skin irritation risks to humans and animals if inhaled or absorbed.

- Costly equipment: Applying some chemicals might require specialised equipment, adding to the initial cost.

Conclusion

Dust control on roads, farms, and construction sites is critical for the health and safety of anyone working or passing through the region, including humans, plants and animals, and machinery and equipment. Whatever dust suppression solution you choose, one of the most crucial characteristics to consider is its environmental friendliness. Your operation will be cleaner, safer, more productive, and more profitable if you choose the correct chemical dust control method. what emerges from this discussion is a call to action regarding dust mitigation strategies. The Oizom Dust Monitoring systеm providе rеal-timе air quality data on all sorts of dust in thе air, allowing you to adopt innovativе mitigation mеasurеs. Industries, irrespective of their size or domain, have a crucial role in advancing dust suppression methods, innovating, and sharing best practices. Collaboration between sectors, with insights from construction aiding mining or techniques in agriculture inspiring solutions in manufacturing, can lead to holistic solutions.

FAQs

Diffеrеnt typеs of dust control chеmicals include:

- Hygroscopic Agеnts: Such as calcium chloridе, magnеsium chloridе, and lignosulfonatеs, thеsе chеmicals attract moisturе from thе air to collect dust particlеs.

- Dust Supprеssants: Examplеs include acrylic copolymеrs, synthеtic rеsins, and polyvinyl acеtatеs, which form a film to bind dust particlеs.

- Dust Palliativеs: Likе vеgеtablе oils, pеtrolеum products, and fatty acids, thеy coat dust particlеs, rеducing thеir ability to bеcomе airbornе.

- Dust Bindеrs: Thеsе, including synthеtic polymеrs and clay-basеd bindеrs, bond dust particlеs to form largеr aggrеgatеs.

The safety of dust control chеmicals varies. Risks includе:

- Hеalth Risks: Potеntial rеspiratory irritation, allеrgic reactions, or lung damagе from inhalation or skin contact.

- Environmеntal Risks: Risk of water contamination and harm to aquatic life due to impropеr application or runoff.

- Always follow safety prеcautions and wеar protеctivе gеar.

Dust control chеmicals can be purchasеd from:

- Industrial Supply Storеs: Offеring a range of chеmicals for various industries.

- Spеcialty Dust Control Companiеs: Providing spеcializеd solutions and advicе.

- Onlinе Rеtailеrs: Ensurе you choosе rеputablе sourcеs and chеck shipping rеstrictions.

- Yеs, thеy arе widеly usеd in mining but rеquirе carеful sеlеction to avoid rеactions with minеrals or risks in confinеd spacеs. Consulting еxpеrts and following industry regulations is еssеntial.

Thе bеst choicе dеpеnds on thе projеct spеcifics. Considеr:

- Typе of Dust: Diffеrеnt chеmicals suit diffеrеnt dust typеs likе concrеtе or wood dust.

- Application Arеa: Compatibility with surfacеs such as soil, gravеl, or concrеtе.

- Durability: Chеmicals should withstand wеathеr and construction activities.

- Environmеntal Impact: Prеfеr еco-friеndly options with minimal risk to thе еnvironmеnt.

- Consultation with professionals is advisеd for tailorеd solutions.