Summary

The automotive sector significantly contributes to air quality through the emissions of CO₂, NOx, PM, and VOCs, thereby shaping the climate, urban settings, and ecosystems around the world. Monitoring real-time air quality in vehicular facilities helps track these pollutants in major zones, optimize performance, maintain regulatory compliance, and support sustainability goals. By targeting primary sources of emissions, such as paint shops, assembly lines, and vehicle transport areas, manufacturers can actively control environmental exposure and enhance workplace safety. Ultimately, implementing continuous monitoring systems enables data-driven strategies to reduce emissions, optimize operational efficiency, and foster a cleaner, more efficient automotive sector.

How Air Quality Monitoring Helps the Automotive Industry?

The automotive sector is a key pillar of international mobility and economic growth; however, its benefits come at a significant environmental cost. Cars and industrial processes emit a combination of pollutants, carbon dioxide (CO₂), nitrogen oxides (NOx), particulate matter (PM), and volatile organic compounds (VOCs) that contribute to climate change, urban smog, and environmental degradation. At the international scale, road transportation accounts for nearly 15% of CO₂ emissions from fossil fuels. In India, the transport sector accounts for approximately 10–12% of national greenhouse gas emissions. Cities like Delhi and Mumbai frequently experience toxic surges of air pollution due to their dense traffic.

Apart from the statistics, emissions from automotive operations impact air quality, nearby ecosystems, and the overall environment in subtle yet significant ways. Manufacturers, policymakers, and communities need to determine the extent and impact of these emissions, making air quality management more than just an operational requirement with the responsibility for sustainable industrial development.

The Environmental and Health Impact of Emissions in the Automotive Industry

The automotive industry, while driving economic growth and mobility, is also a significant source of environmental stress. Vehicles release a mix of pollutants, including carbon dioxide (CO₂), nitrogen oxides (NOx), particulate matter (PM), and volatile organic compounds (VOCs), which contribute not only to local air quality issues but also to broader environmental concerns. Road transport contributes around 15% of global CO₂ emissions and about 10–12% of India’s greenhouse gases, highlighting the automotive sector’s significant impact. With cities like Delhi already facing massive surges in NOx and PM from traffic, controlling emissions at automotive plants becomes crucial to avoid amplifying the issue.

Apart from greenhouse gases, automotive emissions play a crucial role in urban smog formation, acid rain, and the weakening of local ecosystems. Even a minor reduction in vehicle emissions can enhance visibility, reduce urban heat islands, and reduce the settling of harmful pollutants into soil and water bodies. While the health impacts of exhaust emissions, such as respiratory irritation from PM2.5 or ozone formation from NOx, are real, the bigger picture is how these emissions affect climate, urban environments, and natural ecosystems, building a strong case for monitoring and managing air quality in the automotive sector.

Why is Real-Time Air Quality Monitoring Essential in Automotive Plants?

Automotive facilities are complex settings where emissions occur from multiple processes at various stages of production.

Real-time monitoring facilities can detect surges in VOCs during painting operations, allowing for immediate adjustments to minimize harmful emissions and enhance worker safety. Similarly, monitoring NOx and PM emissions improves combustion processes and reduces the environmental impact of vehicles. Real-time air quality monitoring opens a window into this dynamic world, enabling manufacturers to track pollutants such as nitrogen oxides (NOx), volatile organic compounds (VOCs), and particulate matter (PM) once they are released.

The advantages are numerous. At the operational level, around-the-clock monitoring enables plants to maintain regulatory compliance, optimize ventilation and filtration systems, and identify emission hotspots before they become costly transgressions. Beyond the immediate context, monitoring supports sustainability initiatives and ESG reporting as evidence of commitment to environmental stewardship while safeguarding the surrounding coobal environment in which regulatory expectations are closing in and stakeholders are requiring greater transparency, real-time monitoring of air quality is no longer discretionary; it is a necessary tool for effective, responsible, and forward-thinking auto manufacturing.

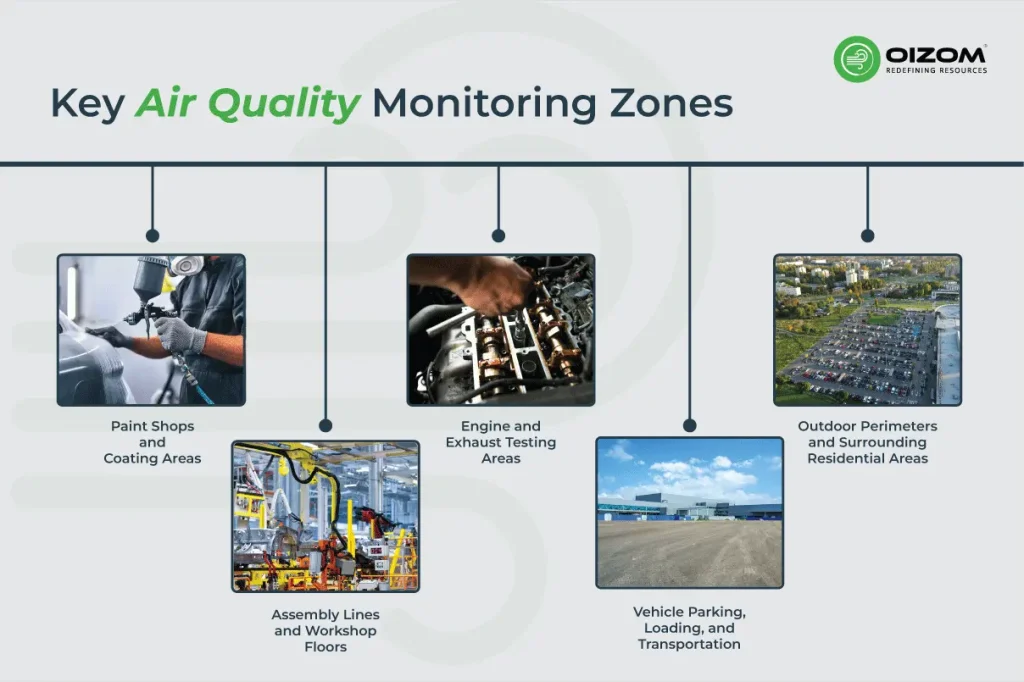

Primary Zones for Air Quality Monitoring in Automotive Plants

Successful automotive plant air quality management involves strategic monitoring in multiple zones, both indoor and outdoor. Each zone contains unique emission sources and high-priority pollutants requiring attention:

Paint Shops and Coating Areas

Purpose of Monitoring: Intensive use of paints, solvents, and coatings emits volatile organic compounds (VOCs) and fine particulate matter (PM). Monitoring assures a safe working environment and compliance with regulations.

Priority Pollutants: VOCs, PM2.5, PM10, and occasional NOx from nearby combustion devices.

Assembly Lines and Workshop Floors

Reason for Monitoring: Operations of machinery, welding, and material transportation can release particulate matter and chemical fumes. Real-time monitoring facilitates compliance with occupational safety and air quality regulations.

Priority Pollutants: PM2.5, PM10, metal fumes, and trace VOCs.

Engine and Exhaust Testing Areas

Reason for Monitoring: Vehicles releasing NOx, CO, and PM during testing. Continuous monitoring enables instant mitigation and compliance with emission standards.

Priority Pollutants: NOx, CO, PM2.5, PM10.

Vehicle Parking, Loading, and Transportation Areas

Reason for Monitoring: Inactive transport and logistics areas in automotive plants, warehouses, or service centers can accumulate engine emissions. Monitoring these areas helps control worker exposure and supports environmental reporting.

Priority Pollutants: CO, NOx, PM2.5, VOCs.

Outdoor Perimeters and Surrounding Residential Areas

Purpose for Monitoring: Emissions may exceed plant limits, affecting nearby communities. Monitoring ensures openness and informs mitigation efforts.

Priority Pollutants: NOx, PM, VOCs, CO.

By prioritizing these major areas, the automotive industry can achieve comprehensive air quality monitoring, safeguard workers, comply with regulations, and reduce its environmental footprint.

Benefits of Integrating Air Quality Monitoring Systems

Implementation of real-time air quality monitoring systems in vehicle manufacturing facilities yields several operational and strategic advantages:

Compliance with Regulations

Continuous monitoring of pollutants, such as NOx, VOCs, CO, and PM, ensures that emissions remain within allowable levels, thereby minimizing the chance of penalties and fines.

Enhanced Workplace Safety

Tracking high-risk areas, such as paint booths or engine test stations, helps maintain safe air quality for workers by detecting VOCs, PM2.5, and other toxic emissions.

Operational Efficiency

Timely data enables timely corrections to processes such as painting, welding, and engine testing, as well as optimal ventilation, ultimately saving on unnecessary energy consumption.

Sustainability and ESG Reporting

Effective monitoring of major pollutants enhances environmental reporting, helps in achieving ESG goals, and strengthens the plant’s commitment to sustainability.

Early Identification of Emission Peaks

Instant identification of sudden peaks in NOx, PM, or VOC levels is possible, allowing for corrective action before they escalate into major environmental or operational problems.

Protection of Communities and Environment

Emission tracking at plant boundaries and transport areas helps prevent or mitigate the effects on nearby communities and the environment, demonstrating corporate accountability.

Data-Driven Decision Making

Long-term data assembly enables plants to identify trends, streamline processes, and schedule upgrades or actions in response to actual emission trends, rather than estimates.

Challenges Faced in Air Quality Management in the Automotive Industry

Air quality management in motor plants entails overcoming several technical and operational challenges:

Sensor Limitations and Accuracy

Providing accurate and reliable measurements for diverse pollutants in dynamic plant environments can be challenging due to cross-sensitivity and calibration requirements.

High Implementation and Maintenance Expenses

Implementing extensive monitoring systems and maintaining sensor operations over time is a high-cost undertaking for some plants.

Data Management Complexity

Enduring monitoring generates vast amounts of data that require proper storage, analysis, and interpretation to be useful.

Integration with Existing Systems

Integrating air quality monitoring into existing plant operations and automation infrastructures may involve technical know-how and procedural modifications.

Regulatory Compliance and Reporting

Compliance with varied and changing environmental criteria in different regions makes monitoring and reporting more challenging.

Employee Awareness and Training

Training employees to monitor systems, accurately interpret results, and take prompt action is essential, but it is generally complex.

Environmental Variability

Other elements, such as weather conditions, ventilation adjustments, and local traffic, can affect measurements, making uniform monitoring and interpretation challenging.

How Oizom’s Air Quality Monitoring Solutions Fit in the Automotive Industry?

Oizom’s air quality monitoring systems offer automotive plants a comprehensive and actionable approach to controlling emissions and mitigating environmental impacts. Through real-time monitoring of major pollutants, including NOx, PM2.5, PM10, VOCs, and CO, these systems enable plants to track emissions in critical areas such as paint shops, assembly lines, engine testing facilities, and vehicle transport areas.

The advantages are threefold: Oizom solutions help facilities meet regulatory compliance, streamline operations, and lower their environmental impact. Real-time alerts enable rapid actions when emission levels exceed the limits, thus minimizing ecological and operational risks. Moreover, constant monitoring supports sustainability efforts and ESG reporting, which shows a focus on ethical manufacturing operations.

Through modular and scalable deployment models, Oizom monitoring systems can be configured to meet the specific needs of various automotive plants, both in India and abroad, allowing producers to adopt a proactive, data-driven approach to managing air quality.

Conclusion

Air quality monitoring is no longer optional but a crucial requirement in the automotive sector; it is a key element for responsible production and environmental responsibility. Real-time monitoring solutions, such as those provided by Oizom, enable factories to monitor pollutants, streamline operations, and remain compliant with regulations while safeguarding the community and ecosystem. As the industry focuses on more rigid emission norms and sustainability goals, adopting advanced monitoring solutions will be central to their fulfillment. Going forward, proactive management of air quality will reduce environmental impact while driving innovation, efficiency, and a cleaner automotive manufacturing future globally.

FAQs

NOx, VOCs, particulate matter (PM2.5 & PM10), CO, and metal fumes.

Key challenges include sensor accuracy, high costs, large data volumes, integration with plant systems, regulatory compliance, employee training, and environmental variability.

Paint shops, assembly lines, engine testing areas, vehicle parking/loading zones, and plant perimeters.