Dust Monitoring – PM100

Real-time dust monitoring helps assess air quality and create a plan to reduce or prevent exposure to harmful PM levels.

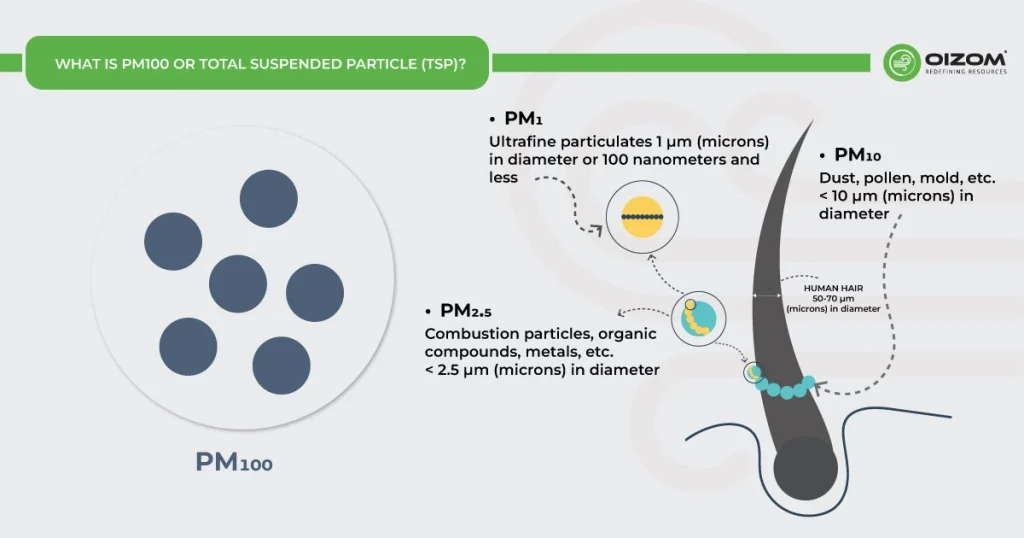

The particulate matter less than or equal to 100 micrometers in diameter is collectively known as PM100 or Total Suspended Particle. They are also known as “inhalable dust,” as this fraction of the particulate matter can enter the nose and/or mouth while breathing and gets deposited in the air passages between the mouth, the nose, and the larynx. Once released into the atmosphere, they tend to settle as they are heavier. Examples include wood particles, dust, etc.

At first glance, particulate matter might seem pretty simple to grasp. It’s just dust and tiny particles floating around in the air, right? There’s no need to dig out those old high school chemistry books for this one! But the reality is particulate matter is a lot more complex than it appears. Its environmental and health impacts are significant, and it’s something we should all be paying closer attention to.

So, what exactly is particulate matter (PM100)/TSP? Where does it come from? This article covers information on PM100, its sources in the ambient air, health and environmental impact, possible corrective measures, the need for PM100 monitors, and different methods of PM100 monitoring.

The particulate matter less than or equal to 100 micrometers in diameter is collectively known as PM100 or Total Suspended Particle. They are also known as “inhalable dust,” as this fraction of the particulate matter can enter the nose and/or mouth while breathing and gets deposited in the air passages between the mouth, the nose, and the larynx. Once released into the atmosphere, they tend to settle as they are heavier. Examples include wood particles, dust, etc.

At first glance, particulate matter might seem pretty simple to grasp. It’s just dust and tiny particles floating around in the air, right? There’s no need to dig out those old high school chemistry books for this one! But the reality is particulate matter is a lot more complex than it appears. Its environmental and health impacts are significant, and it’s something we should all be paying closer attention to.

So, what exactly is particulate matter (PM100)/TSP? Where does it come from? This article covers information on PM100, its sources in the ambient air, health and environmental impact, possible corrective measures, the need for PM100 monitors, and different methods of PM100 monitoring.

The natural sources of particulate matter are wind-blown dust from open land, dirt, soil erosion, etc.

Anthropogenic sources of PM100 include:

The natural sources of particulate matter are wind-blown dust from open land, dirt, soil erosion, etc.

Anthropogenic sources of PM100 include:

The primary step is dust monitoring to identify the areas with high particulate levels. You can utilize air quality alerts to protect yourself and others when PM reaches hazardous levels. In addition to this, the following corrective measures can be taken:

The primary step is dust monitoring to identify the areas with high particulate levels. You can utilize air quality alerts to protect yourself and others when PM reaches hazardous levels. In addition to this, the following corrective measures can be taken:

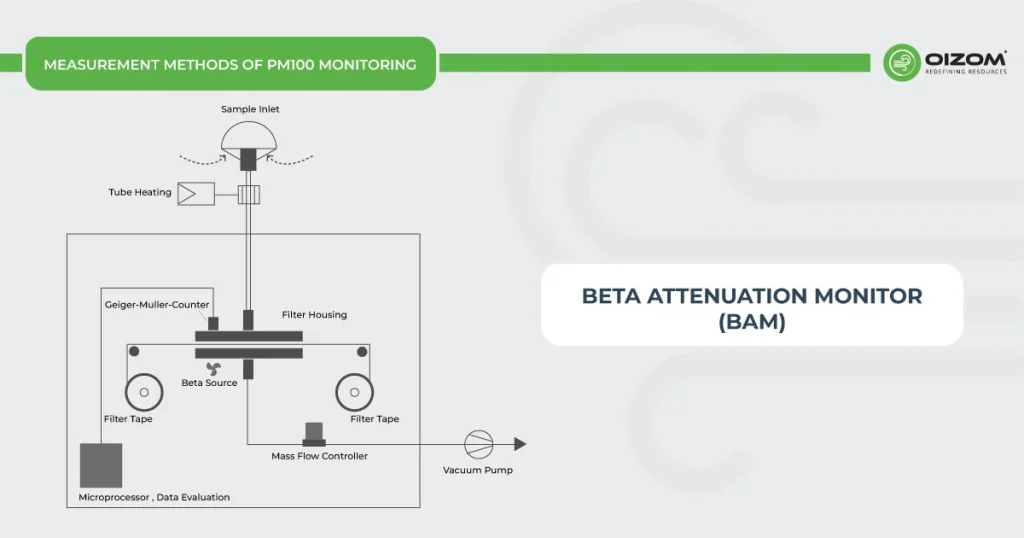

Beta Attenuation Monitor (BAM) – The dust monitoring based on the BAM principle measures the particle mass density using beta radiation attenuation. The particulates in the ambient air drawn into the dust monitor are deposited on a paper-band filter and exposed to beta rays (i.e., electrons with energies in the 0.01 to 0.1 MeV range), which get attenuated as a function of the particulate mass. The beta count reduces with an increase in the PM mass, which is recorded by the detector and converted to concentration.

Beta Attenuation Monitor (BAM) – The dust monitoring based on the BAM principle measures the particle mass density using beta radiation attenuation. The particulates in the ambient air drawn into the dust monitor are deposited on a paper-band filter and exposed to beta rays (i.e., electrons with energies in the 0.01 to 0.1 MeV range), which get attenuated as a function of the particulate mass. The beta count reduces with an increase in the PM mass, which is recorded by the detector and converted to concentration.

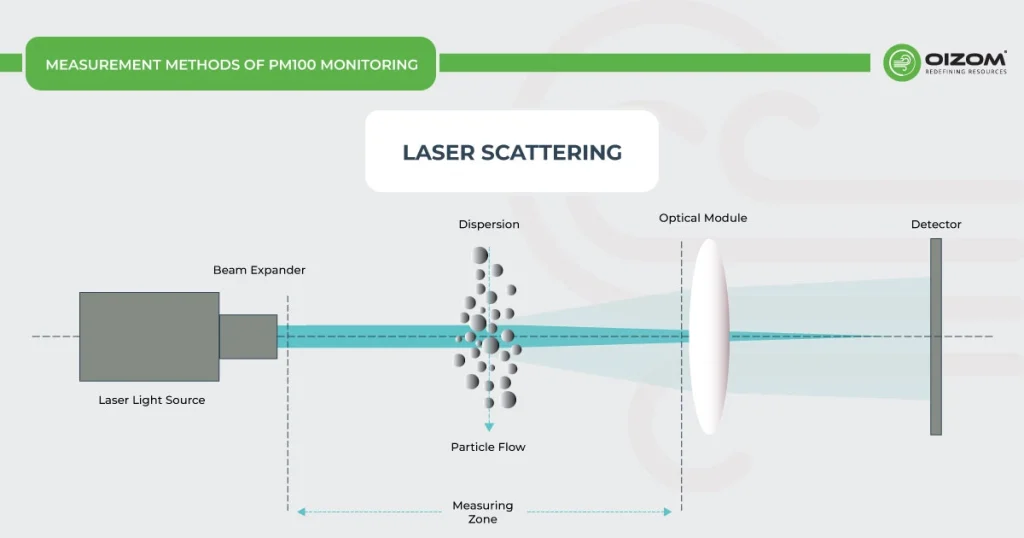

Laser Scattering – The dust monitor, based on the physical principle of light scattering, also known as optical particle counter (OPC), measures dust particles illuminated by laser light at a 90° angle. The light scattered from each particle is collected at approximately 90° by a mirror and detected by a photo-diode. This signal is then fed into a multi-channel size classifier, where a pulse height analyzer is used to classify each pulse proportional to the particle size. The counts in the channel corresponding to PM100 are converted to the concentration of PM100.

Laser Scattering – The dust monitor, based on the physical principle of light scattering, also known as optical particle counter (OPC), measures dust particles illuminated by laser light at a 90° angle. The light scattered from each particle is collected at approximately 90° by a mirror and detected by a photo-diode. This signal is then fed into a multi-channel size classifier, where a pulse height analyzer is used to classify each pulse proportional to the particle size. The counts in the channel corresponding to PM100 are converted to the concentration of PM100.

[Source from researchgate.net]

[Source from researchgate.net]

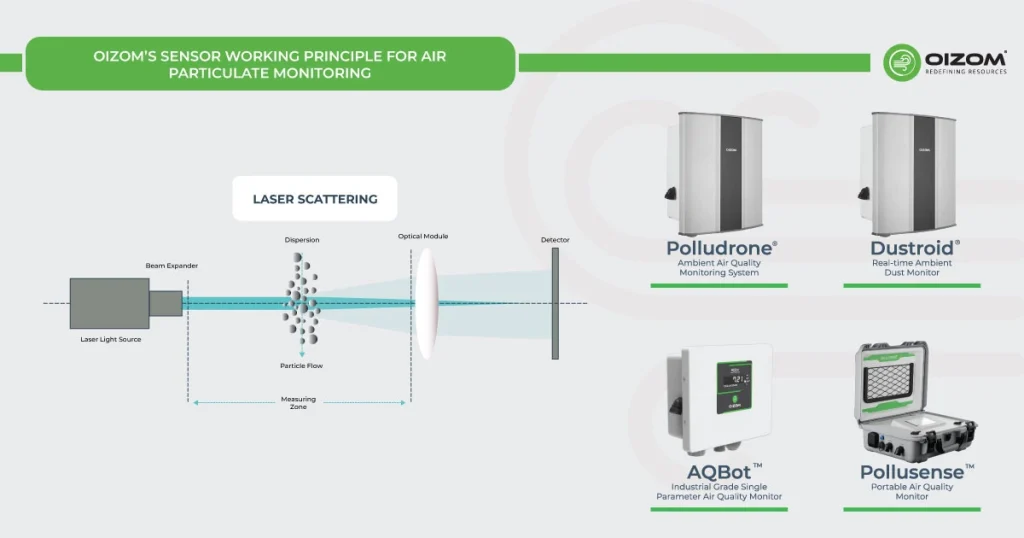

Our Particulate Matter sensor module is engineered to accurately measure PM1, PM2.5, PM10, and PM100 concentrations in ambient air, providing real-time data on atmospheric particulate matter levels. The sensor’s advanced support electronics ensure compactness and reliability, making it a robust solution for continuous air quality monitoring.

These sensors work on laser scattering technology with a heated inlet to eliminate moisture and ensure accurate air quality data. Integrating a heavy-duty fan and advanced lasers guarantees precise data and durability, making these sensors ideal for outdoor applications requiring real-time air quality insights.

These advanced particulate matter sensor modules are utilized in our outdoor air quality monitoring systems, such as Polludrone and AQBot. Additionally, these modules are a key component in our specialized ambient dust monitor Dustroid. These versatile sensors are used in a variety of applications, including national air quality monitoring, environmental health impact assessments, construction site monitoring, mining, smart cities, and air quality research projects. By providing real-time particle concentration data, Oizom’s PM sensor modules support a wide array of environmental monitoring needs, ensuring accurate and reliable air quality data for diverse applications.

Our particulate monitoring sensors are calibrated with reference stations, housing Beta Attenuation Monitor, BAM-1020, which significantly enhances the data accuracy and reliability of our sensors, ensuring high-quality air quality monitoring results.

Our Particulate Matter sensor module is engineered to accurately measure PM1, PM2.5, PM10, and PM100 concentrations in ambient air, providing real-time data on atmospheric particulate matter levels. The sensor’s advanced support electronics ensure compactness and reliability, making it a robust solution for continuous air quality monitoring.

These sensors work on laser scattering technology with a heated inlet to eliminate moisture and ensure accurate air quality data. Integrating a heavy-duty fan and advanced lasers guarantees precise data and durability, making these sensors ideal for outdoor applications requiring real-time air quality insights.

These advanced particulate matter sensor modules are utilized in our outdoor air quality monitoring systems, such as Polludrone and AQBot. Additionally, these modules are a key component in our specialized ambient dust monitor Dustroid. These versatile sensors are used in a variety of applications, including national air quality monitoring, environmental health impact assessments, construction site monitoring, mining, smart cities, and air quality research projects. By providing real-time particle concentration data, Oizom’s PM sensor modules support a wide array of environmental monitoring needs, ensuring accurate and reliable air quality data for diverse applications.

Our particulate monitoring sensors are calibrated with reference stations, housing Beta Attenuation Monitor, BAM-1020, which significantly enhances the data accuracy and reliability of our sensors, ensuring high-quality air quality monitoring results.

1. What is PM100 or Total Suspended Particle (TSP)?

PM stands for particulate matter (also known as particle pollution), a mixture of solid particles and liquid droplets prevalent in the air. Dust, dirt, soot, and smoke are examples of large particles that can be seen with the naked eye. For air quality regulatory purposes, these atmospheric particles are defined by their diameter. The particulate matter less than or equal to 100 micrometers in diameter is collectively known as PM100 or Total Suspended Particle. They are also known as “inhalable dust,” as this fraction of the particulate matter can enter the nose and/or mouth while breathing and gets deposited in the air passages between the mouth, the nose, and the larynx. Once released into the atmosphere, they tend to settle as they are heavier. Examples include wood particles, dust, etc.

At first glance, particulate matter might seem pretty simple to grasp. It’s just dust and tiny particles floating around in the air, right? There’s no need to dig out those old high school chemistry books for this one! But the reality is particulate matter is a lot more complex than it appears. Its environmental and health impacts are significant, and it’s something we should all be paying closer attention to.

So, what exactly is particulate matter (PM100)/TSP? Where does it come from? This article covers information on PM100, its sources in the ambient air, health and environmental impact, possible corrective measures, the need for PM100 monitors, and different methods of PM100 monitoring.

The particulate matter less than or equal to 100 micrometers in diameter is collectively known as PM100 or Total Suspended Particle. They are also known as “inhalable dust,” as this fraction of the particulate matter can enter the nose and/or mouth while breathing and gets deposited in the air passages between the mouth, the nose, and the larynx. Once released into the atmosphere, they tend to settle as they are heavier. Examples include wood particles, dust, etc.

At first glance, particulate matter might seem pretty simple to grasp. It’s just dust and tiny particles floating around in the air, right? There’s no need to dig out those old high school chemistry books for this one! But the reality is particulate matter is a lot more complex than it appears. Its environmental and health impacts are significant, and it’s something we should all be paying closer attention to.

So, what exactly is particulate matter (PM100)/TSP? Where does it come from? This article covers information on PM100, its sources in the ambient air, health and environmental impact, possible corrective measures, the need for PM100 monitors, and different methods of PM100 monitoring.

2. Sources

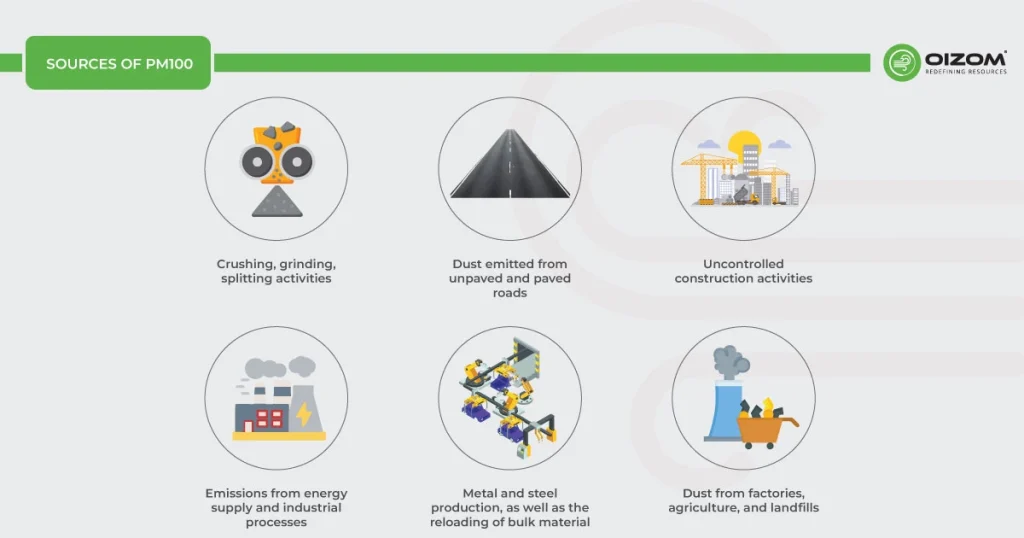

When we think about air pollution, we usually picture factories and power plants as the main sources. While they do contribute to dust, there are plenty of other sources out there, too. In fact, particulate matter can come from both primary sources, like emissions, or secondary sources, where particles form through chemical reactions in the air. The natural sources of particulate matter are wind-blown dust from open land, dirt, soil erosion, etc.

Anthropogenic sources of PM100 include:

The natural sources of particulate matter are wind-blown dust from open land, dirt, soil erosion, etc.

Anthropogenic sources of PM100 include:

- Crushing, grinding, splitting activities

- Dust emitted from unpaved and paved roads

- Uncontrolled construction activities

- Dust from factories, agriculture, and landfills.

- Emissions from industrial processes

- Metal and steel production, as well as the reloading of bulk material

3. Health & Environmental Impact of PM100

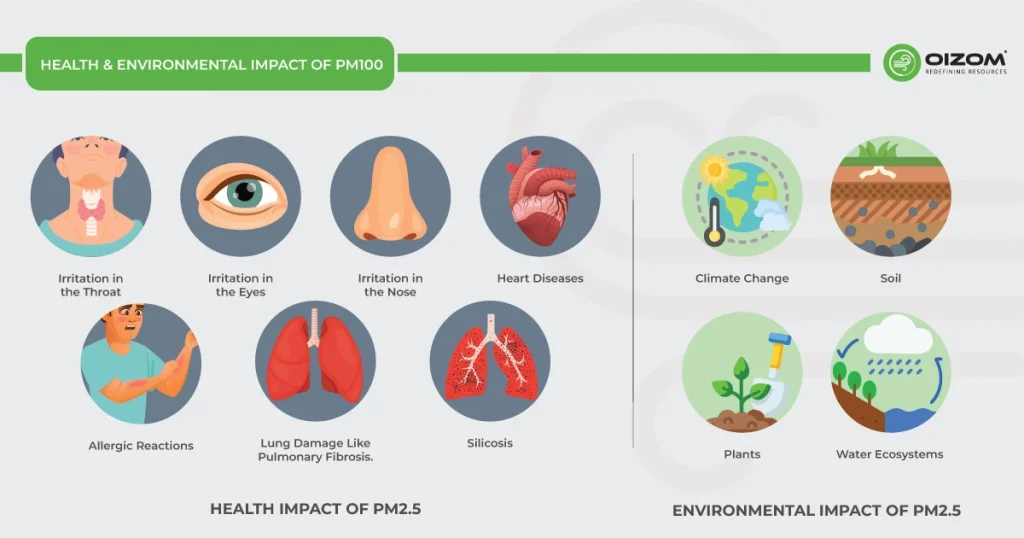

Dust consists of solid particles ranging in size from less than 1 µm to 100 µm, floating in the air and carried by the wind. Though they seem harmless, these small particles pose serious risks to human health, the environment, transportation safety, and the global economy.

Health Impact

The impact of particulate matter on human health depends on its size. Particles smaller than 100μm can enter the nose and throat. Most are trapped by nasal hairs and cleared by sneezing, coughing, or blowing your nose, but some may still reach the airways and lungs. When PM100 particles are inhaled and not cleared from the respiratory system, they can stay in place and cause health issues like allergic reactions, heart disease, and silicosis. They can irritate the nose, throat, and eyes. Short-term exposure worsens existing respiratory conditions like asthma, while long-term exposure may increase the risk of respiratory-related deaths. Some particles are toxic and pose additional risks due to their hazardous nature. For example, hardwood dust can lead to nasal cancer, dust from lead-containing alloys can cause poisoning, and metal dust with mercury, lead, or chromium can cause lung damage like pulmonary fibrosis. OSHA Permissible Exposure Limit for Total Dust:- The term “total dust” encompasses all airborne particles in a workplace, irrespective of their size or composition. OSHA’s permissible exposure limit for total dust is 15 milligrams per cubic meter (mg/m³) over an 8-hour time-weighted average.

- This standard is essential for woodworking, construction, and manufacturing industries, where dust generation is common. Compliance with these regulations, through measures such as effective ventilation, dust extraction systems, and personal protective equipment, is crucial to prevent respiratory conditions like COPD and silicosis and ensure a safer working environment.

Environmental Impact

Particulate matter has been found in numerous scientific studies to reduce visibility while also negatively impacting climate, ecosystems, and materials (Albedo Effect). PM, primarily PM100, affects visibility by altering how light is absorbed and scattered in the atmosphere. Regarding climate change, certain components of the ambient PM mixture promote global warming (e.g., black carbon). In contrast, others have a cooling effect (e.g., nitrate and sulfate), resulting in ambient PM having both warming and cooling capabilities. Additionally, settling the air-borne particles on plants, soil, and water ecosystems has harmful effects on them. The metal and organic compounds reduce plant growth and yield, while the deposition of PM into water bodies affects its quality and clarity.4. Possible Corrective Measures

The primary step is dust monitoring to identify the areas with high particulate levels. You can utilize air quality alerts to protect yourself and others when PM reaches hazardous levels. In addition to this, the following corrective measures can be taken:

The primary step is dust monitoring to identify the areas with high particulate levels. You can utilize air quality alerts to protect yourself and others when PM reaches hazardous levels. In addition to this, the following corrective measures can be taken:

- Look at your local AQI readings.

- Limit outdoor activities and close windows and vents during times of high air pollution.

- Skip the morning exercise if AQI exceeds its limit.

- Wear a pollution mask.

- Eliminate the use of the fireplace, wood stove, gas-powered lawn, or garden equipment.

- Invest in an air quality monitoring system.

- Avoid areas with traffic congestion, construction activities, or unpaved roads. Breathing such polluted air daily also leads to health effects in the long run.

5. Measurement Methods of Dust Monitoring

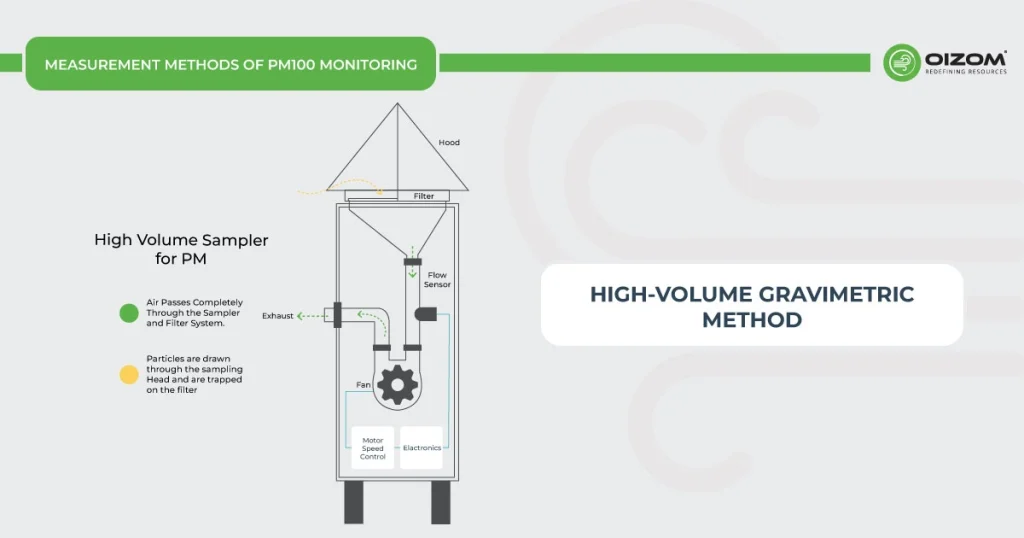

Different working principles for dust monitoring in the ambient environment are Gravimetric, Beta Attenuation (BAM), and Laser scattering. High-volume Gravimetric Method – The dust monitors based on the gravimetric principle take in the ambient air for 24 hours at a constant flow rate through a size-selective inlet that only allows particulate matter with an aerodynamic diameter of 100µm or less to pass through. The particulate matter is collected onto a pre-weighed filter conditioned at constant temperature and humidity conditions. After the 24-hour sampling period, the filter is conditioned under the same temperature-humidity conditions and reweighted. The difference in the weight corresponds to the mass collected on the filter, which, along with the known flow rate, sampling period, and the total volume of the air sampled, is used to calculate the PM100 concentration. Beta Attenuation Monitor (BAM) – The dust monitoring based on the BAM principle measures the particle mass density using beta radiation attenuation. The particulates in the ambient air drawn into the dust monitor are deposited on a paper-band filter and exposed to beta rays (i.e., electrons with energies in the 0.01 to 0.1 MeV range), which get attenuated as a function of the particulate mass. The beta count reduces with an increase in the PM mass, which is recorded by the detector and converted to concentration.

Beta Attenuation Monitor (BAM) – The dust monitoring based on the BAM principle measures the particle mass density using beta radiation attenuation. The particulates in the ambient air drawn into the dust monitor are deposited on a paper-band filter and exposed to beta rays (i.e., electrons with energies in the 0.01 to 0.1 MeV range), which get attenuated as a function of the particulate mass. The beta count reduces with an increase in the PM mass, which is recorded by the detector and converted to concentration.

Laser Scattering – The dust monitor, based on the physical principle of light scattering, also known as optical particle counter (OPC), measures dust particles illuminated by laser light at a 90° angle. The light scattered from each particle is collected at approximately 90° by a mirror and detected by a photo-diode. This signal is then fed into a multi-channel size classifier, where a pulse height analyzer is used to classify each pulse proportional to the particle size. The counts in the channel corresponding to PM100 are converted to the concentration of PM100.

Laser Scattering – The dust monitor, based on the physical principle of light scattering, also known as optical particle counter (OPC), measures dust particles illuminated by laser light at a 90° angle. The light scattered from each particle is collected at approximately 90° by a mirror and detected by a photo-diode. This signal is then fed into a multi-channel size classifier, where a pulse height analyzer is used to classify each pulse proportional to the particle size. The counts in the channel corresponding to PM100 are converted to the concentration of PM100.

[Source from researchgate.net]

[Source from researchgate.net]

6. Oizom’s Sensor Working Principle for Dust Monitoring

At Oizom, we offer various Particulate Matter (PM) sensors, including PM1, PM2.5, PM10, and PM100, designed for accurate air quality monitoring across various particle sizes. Our Particulate Matter sensor module is engineered to accurately measure PM1, PM2.5, PM10, and PM100 concentrations in ambient air, providing real-time data on atmospheric particulate matter levels. The sensor’s advanced support electronics ensure compactness and reliability, making it a robust solution for continuous air quality monitoring.

These sensors work on laser scattering technology with a heated inlet to eliminate moisture and ensure accurate air quality data. Integrating a heavy-duty fan and advanced lasers guarantees precise data and durability, making these sensors ideal for outdoor applications requiring real-time air quality insights.

These advanced particulate matter sensor modules are utilized in our outdoor air quality monitoring systems, such as Polludrone and AQBot. Additionally, these modules are a key component in our specialized ambient dust monitor Dustroid. These versatile sensors are used in a variety of applications, including national air quality monitoring, environmental health impact assessments, construction site monitoring, mining, smart cities, and air quality research projects. By providing real-time particle concentration data, Oizom’s PM sensor modules support a wide array of environmental monitoring needs, ensuring accurate and reliable air quality data for diverse applications.

Our particulate monitoring sensors are calibrated with reference stations, housing Beta Attenuation Monitor, BAM-1020, which significantly enhances the data accuracy and reliability of our sensors, ensuring high-quality air quality monitoring results.

Our Particulate Matter sensor module is engineered to accurately measure PM1, PM2.5, PM10, and PM100 concentrations in ambient air, providing real-time data on atmospheric particulate matter levels. The sensor’s advanced support electronics ensure compactness and reliability, making it a robust solution for continuous air quality monitoring.

These sensors work on laser scattering technology with a heated inlet to eliminate moisture and ensure accurate air quality data. Integrating a heavy-duty fan and advanced lasers guarantees precise data and durability, making these sensors ideal for outdoor applications requiring real-time air quality insights.

These advanced particulate matter sensor modules are utilized in our outdoor air quality monitoring systems, such as Polludrone and AQBot. Additionally, these modules are a key component in our specialized ambient dust monitor Dustroid. These versatile sensors are used in a variety of applications, including national air quality monitoring, environmental health impact assessments, construction site monitoring, mining, smart cities, and air quality research projects. By providing real-time particle concentration data, Oizom’s PM sensor modules support a wide array of environmental monitoring needs, ensuring accurate and reliable air quality data for diverse applications.

Our particulate monitoring sensors are calibrated with reference stations, housing Beta Attenuation Monitor, BAM-1020, which significantly enhances the data accuracy and reliability of our sensors, ensuring high-quality air quality monitoring results.

7. Why Choose Oizom PM Sensor?

- Compact: Our sensors are small and easy to install, perfect for use in any space, making them ideal for portable air quality monitoring. The Dust sensors come pre-calibrated and can be quickly replaced in just a few minutes by removing and replacing the old sensor with a new one.

- Durable: The PM sensor has an expected lifespan of 18 months.

- The dust measurement by the laser scattering principle overestimates the PM concentration levels in condensing high humidity conditions. The data accuracy in such conditions is maintained by dehumidification of the air sample using a heated inlet.

- It reduces the relative humidity of the air sample by 30-40%, eliminating its interference in the particulate measurement.

- PM sensors work on laser-based scattering principles and Advanced algorithms.

8. Reasons why Dust Monitoring is Important:

- Dust is a constant presence in almost every business, whether it’s construction sites with their nonstop activity, manufacturing plants with vibrating machines, or even quiet office spaces where paper and equipment share the same environment. These particles, from tiny ones you can’t see to larger ones, can come from everyday processes.

- Regular dust monitoring is more than a standard procedure; it is a proactive approach to ensuring worker safety and health. Dust in industrial zones can pose significant health and safety risks to employees.

- When inhaled, it irritates the eyes, nose, throat, and airways and can penetrate tissues, causing severe diseases like heart attacks, lung cancer, edema, etc., leading to premature death. , etc.

- Dust monitoring is an efficient way to detect high particulate matter concentrations and prevent high-level exposures.

- Real-time dust monitoring helps determine air quality and formulate an action plan to control high levels of PM pollution.