Summary of Blog

Ever wonder what those annoying dust particles at work are all about? It turns out that they have the potential to be far more harmful to your health than merely an annoyance. OSHA states that there are particular dust exposure thresholds that you should be aware of.

It is 15 milligrams per cubic meter for total dust during a period of 8 hours. However, OSHA lowers the limit to 5 milligrams per cubic meter for respirable fractions,

which are more harmful particles that might enter your lungs, such as silica. Not to be overlooked is boron oxide, which is particularly noteworthy because of its potential health hazards. It’s critical to adhere to these guidelines if your employment contains dust to prevent respiratory conditions like silicosis and COPD. Thus, check those dust levels, invest in trustworthy monitoring devices like Dustroid, and ensure everyone wears the appropriate safety gear. Ultimately, a happy workplace is free of illness.”

What are the OSHA levels for dust?

You might wonder why I have chosen the topic of OSHA level for dust for the discussion.

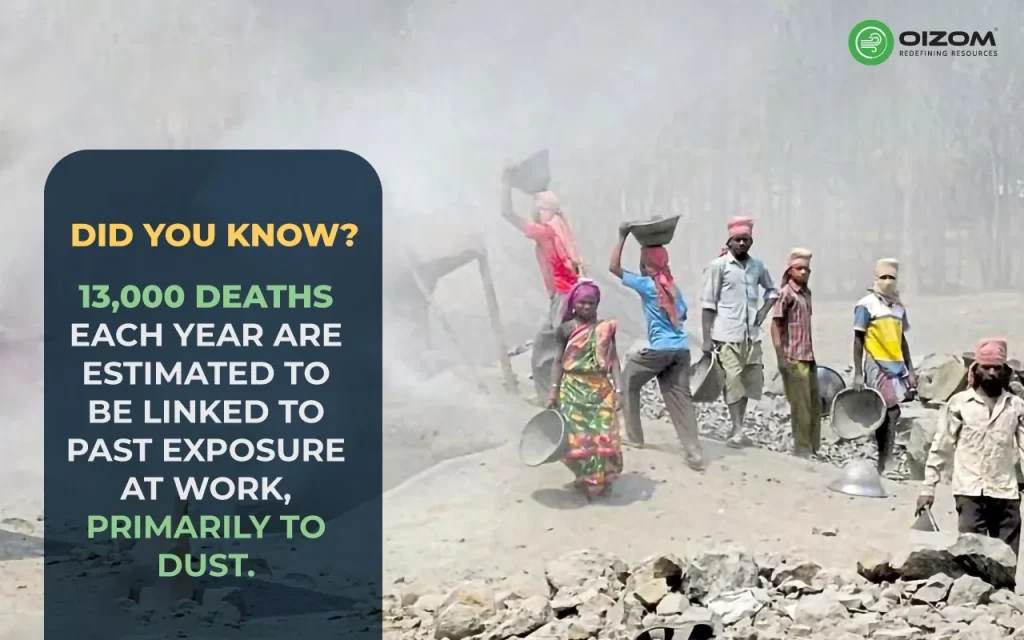

Employees across various occupations work daily, knowing they will be routinely exposed to dust. Dust in the workplace is unavoidable in many professions, including mining, carpentry, construction, and manufacturing. Although regulators like the Occupational Health and Safety Administration (OSHA) require dust protection, workers and managers frequently misunderstand what constitutes a clear and present threat.

This article will provide insights into the OSHA dust levels. Understanding OSHA Dust Regulations is critical for industries seeking to maintain compliance and protect worker health, particularly in locations with high dust levels..

OSHA dust levels

In many industries, decision-makers mandate workers wear dust masks only when specific types of dust are identified as a threat. Obviously, asbestos is the most feared. However, airborne particles such as silica have attracted attention in recent years. Dust that goes unnoticed can severely influence the health and well-being of hardworking people. Dust monitoring generally has two main classifications: respirable dust and total dust.

Total Dust

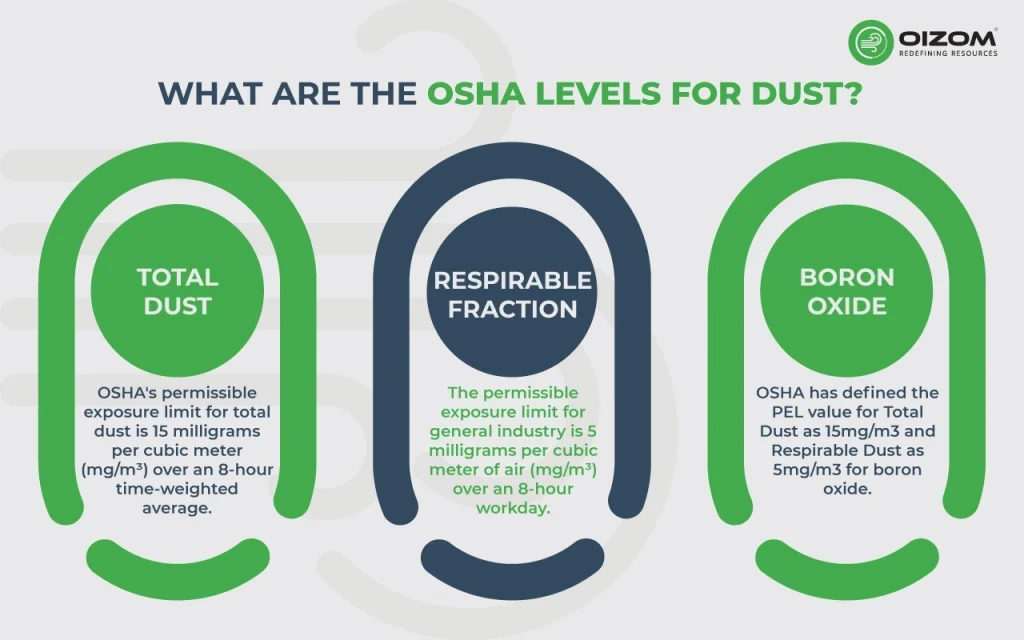

- The term “total dust” encompasses all airborne particles in a workplace, irrespective of their size or composition. OSHA’s permissible exposure limit for total dust is 15 milligrams per cubic meter (mg/m³) over an 8-hour time-weighted average.

- This standard is essential for woodworking, construction, and manufacturing industries, where dust generation is common. Compliance with these regulations, through measures such as effective ventilation, dust extraction systems, and personal protective equipment, is crucial to prevent respiratory conditions like COPD and silicosis and ensure a safer working environment.

Respirable fraction

- Respirable dust is the size fraction that can enter the gas exchange zone of your lungs, although total dust is not size-specific. Respirable dust testing is a size-selective sampling in which a customized sampling apparatus collects only particles of a specific size.

- OSHA has set specific guidelines to control exposure to this dust because it’s more likely to cause serious health problems, like lung disease. The permissible exposure limit for general industry is 5 milligrams per cubic meter of air (mg/m³) over an 8-hour workday.

- It’s super important for workplaces to monitor these levels using reliable devices such as dustroid, which provides real-time accurate data, and its alert module, which receives notifications when it crosses threshold limits. This system can ensure everyone breathes easily and stays healthy.

Boron oxide

Boron oxide, which has a general formula of B2O3, is treated with particular caution by OSHA due to its potential health risks. Boron oxide isn’t just dust; it can affect your health if exposed for long periods. OSHA has defined the PEL value for Total Dust as 15mg/m3 and Respirable Dust as 5mg/m3 for boron oxide. This means that in companies where boron oxide is used, such as glass or ceramics manufacturers, proper ventilation and safety measures must be in place to keep everyone safe from overexposure.

Difference Between Total dust and Respirable fraction

In general, dust monitoring is divided into two categories: respirable dust and total dust. Respirable dust is the size fraction that can enter the gas exchange zone of your lungs, although total dust is not size-specific. Respirable dust testing is a size-selective sampling in which a customized sampling apparatus collects only particles of a specific size.

OSHA defines different permissible exposure limits (PELs) for these categories due to their varying health implications. The PEL is typically 15 mg/m³ for total dust, whereas it is lower at 5 mg/m³ for respirable particles, reflecting the higher risk associated with finer particles. Understanding and monitoring dust with devices such as dustroids that are easy to maintain and reliable because of Low Maintenance. These distinctions are crucial for effective workplace safety and health management.

Conclusion

In conclusion, workers who operate in dusty areas must have access to the appropriate disposable protective gear and clothes. Maintaining a safe and healthy workplace requires an awareness of the complexities of OSHA’s dust regulations. Employers can use extensive resources, including the OSHA website, training courses, state consultation services, and industry-specific requirements, to gain in-depth knowledge and keep up-to-date on the newest advancements in the best dust control techniques.

OSHA sets the limit for total dust at 15 mg/m³ and respirable dust at 5 mg/m³, measured over an 8-hour workday.

The PEL for total dust is 15 mg/m³; respirable dust is 5 mg/m³ over an 8-hour shift.

Lead dust comes from lead-containing materials and is highly toxic. Wood dust, less toxic but still hazardous, arises from cutting or sanding wood.

OSHA standards require engineering controls like ventilation and dust collection, adherence to specific PELs, and the use of personal protective equipment (PPE).