Summary

Industrial air pollution remains a significant environmental and public health concern, stemming from the burning of fossil fuels, chemical reactions, the emission of toxic gases, and particulate matter. Such emissions not only worsen air quality but also lead to respiratory diseases, cardiovascular diseases, and other health harms. Real-time monitoring of industrial emissions is crucial for identifying problem areas, ensuring regulatory compliance, and implementing proactive pollution control strategies. Technological advancements, such as energy-efficient design, carbon capture, a circular economy, and high-tech sensor-based monitoring, aid factories in reducing their environmental impact. By integrating sustainable activities with precise data, industries can harmonize economic progress with environmental protection, safeguarding both human health and the earth.

Introduction

The modern world, bathed in the conveniences of industrialisation, is paradoxically paying the price for its advancements. The factories that once symbolised progress and prosperity have now, to some extent, become synonymous with environmental degradation.

This isn’t merely a topic for debate in academic circles; it’s a tangible, pervasive issue that impacts the air we breathe, the health of our global population, and the ecosystems that sustain life on Earth. This article comprehensively examines the intricate relationship between factories and air pollution, incorporating hard-hitting data, industry insights, and forward-thinking solutions.

What is Factory Pollution? An Overview

Factory pollution refers to the release of harmful gases, chemicals, and particulate matter into the atmosphere as a result of industrial activities. Whether it’s energy generation, manufacturing, or processing raw materials, most factory operations inevitably emit pollutants that degrade air quality.

These emissions can take many forms. Burning fuels to power machinery releases greenhouse gases, such as carbon dioxide and methane, while various chemical processes emit volatile organic compounds (VOCs) that contribute to smog. Factories handling heavy metals or solvents may discharge toxic substances that persist in the environment, and industries such as mining or construction generate fine particulate matter that can penetrate deep into the lungs.

In short, factory pollution is not caused by a single activity but by a combination of energy use, chemical reactions, toxic discharges, and dust production. Together, these pollutants make factories one of the most significant contributors to industrial air pollution worldwide.

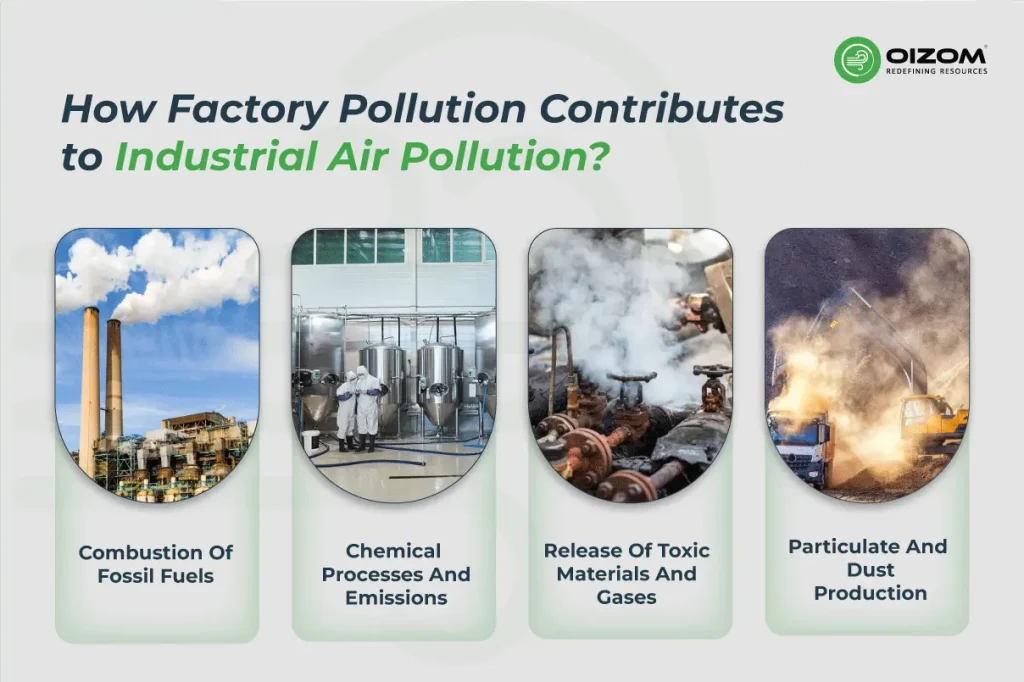

How Factory Pollution Contributes to Industrial Air Pollution?

The labyrinth of industrial processes is diverse and expansive, resulting in a range of pollutants that adversely affect air quality.

Combustion of fossil fuels

One of the pillars of industrial operations, fossil fuels, is a double-edged sword. While they power a significant portion of the world’s factories, the combustion of coal, oil, and natural gas has environmental repercussions that are difficult to ignore. Carbon dioxide (CO2), a primary greenhouse gas, is emitted in vast quantities.

With the industrial sector accounting for approximately 21% of global CO2 emissions, the scale of the problem is evident. Add to this mix other gases, such as methane, which is over 25 times more potent at trapping heat over 100 years than CO2, and the environmental ramifications are severe.

Moreover, the release of nitrogen oxides and sulphur dioxide culminates in the formation of smog and acid rain, both of which are deleterious effects on ecosystems.

Chemical processes and emissions

Beyond fossil fuels, the industrial realm involves a myriad of chemical processes. Petrochemical plants, pharmaceutical factories, and agro-based industries, among others, release a spectrum of chemicals into the atmosphere.

As emitted from paint factories or refineries, VOCs do not remain individual pollutants. They interact with other atmospheric emissions, resulting in secondary pollutants like ground-level ozone, a major respiratory irritant and a significant contributor to urban smog.

Release of toxic materials and gases

While the Industrial Age has ushered in an era of unprecedented growth, it has also witnessed some of the most tragic industrial accidents in history. Instances like the Bhopal gas tragedy aren’t mere historical footnotes but stark reminders of the devastating impact of unbridled toxic emissions.

Factories that deal with heavy metals, chemical solvents, and radioactive materials have the potential to release substances that can persist in the environment, leading to long-term health issues and ecological imbalances.

Particulate and dust production

Dust might seem innocuous, but in the industrial context, it’s anything but. Industries such as mining or construction produce copious amounts of particulate matter (PM). This PM, especially the ultra-fine PM2.5, can penetrate deep into the lungs, causing respiratory and cardiovascular issues.

With industry-related PM accounting for a significant portion of airborne particulates, the scale and gravity of this issue are palpable.

Real-Life Health Risks from Factory and Industrial Air Pollution

Factory pollution doesn’t just linger near industrial zones; it travels through the air, exposing entire populations to harmful pollutants. Over time, this leads to rising cases of respiratory illnesses, cardiovascular problems, and other serious health concerns.

As the world continues its tryst with industrialization, public health stands at the crossroads of progress and pollution. The International Agency for Research on Cancer (IARC) and the World Health Organization (WHO) have consistently identified certain industrial pollutants as carcinogens. Besides cancer, long-term exposure to pollutants like benzene, asbestos, and even certain heavy metals can lead to respiratory diseases, cardiovascular issues, and even neurodegenerative conditions.

Children, in particular, are especially vulnerable. Growing bodies are more susceptible to airborne pollutants. For instance, childhood asthma has sharply risen in many developing nations, directly correlating with proximity to industrial areas. The elderly, especially those with pre-existing conditions, are also at increased risk. Heart attacks, strokes, and chronic obstructive pulmonary disease (COPD) have all been linked to industrial pollutants.

Environmental Damage Linked to Factory Pollution

The damage from factory emissions spreads across ecosystems, altering air, soil, and water quality. These changes disrupt biodiversity, weaken natural resilience, and contribute to broader issues such as climate change and habitat loss.

The environment, our collective shared space, bears the cumulative impact of decades of industrial activity. Ecosystems, from the lush rainforests of the Amazon to the Great Barrier Reef coral reefs, all feel the sting of pollution. Acid rain, formed due to the reaction of sulphur dioxide and nitrogen oxides with water vapour, doesn’t merely affect aquatic ecosystems. It alters soil pH, affecting agriculture and forest covers. The increasing acidity of oceans, a direct consequence of CO2 emissions, poses a significant threat to marine biodiversity.

But the environmental narrative isn’t just about individual species or habitats. It’s about the grand tapestry of biodiversity. Pollinators, such as bees, are affected by pollutants, which decreases pollination and impacts global food chains. With industrial emissions contributing significantly to global warming, the melting of polar ice caps leads to rising sea levels, threatening coastal habitats and human settlements.

Why Monitoring Industrial Air Pollution Is Crucial

Across the world, industries face the dual challenge of sustaining economic growth while keeping emissions under control. Over the past few decades, stricter emission standards and compliance frameworks have helped reduce pollutants such as lead, sulphur dioxide, and carbon monoxide in many regions. Yet, the progress is uneven. While some countries enforce advanced regulations and adopt cleaner technologies, others continue to struggle with outdated systems, limited enforcement, or economic barriers that hinder the transition.

This gap underscores the importance of continuous air quality monitoring. By tracking emissions in real-time, industries can identify problem areas, ensure adherence to regulations, and demonstrate transparency to authorities and the communities they serve. Reliable monitoring also bridges the gap between ambitious policies and on-ground implementation, making compliance measurable rather than aspirational.

Companies like Oizom are helping industries move in this direction by providing advanced monitoring solutions that deliver accurate data, detect anomalies, and integrate seamlessly with industrial operations. With such tools, factories can not only meet regulatory demands but also take proactive steps toward sustainability and community trust.

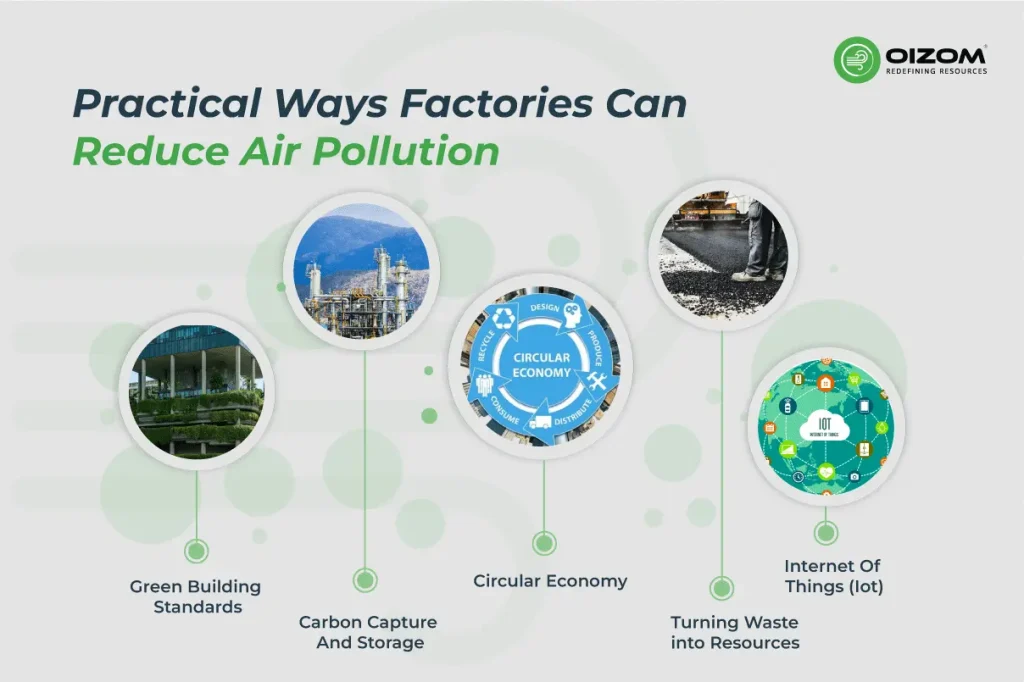

Practical Ways Factories Can Reduce Air Pollution

In the face of such challenges, the silver lining is the emergence of sustainable, eco-friendly measures underpinned by technological innovation and green ethos. Green building standards are no longer niche; they’re becoming the norm. Factories are being designed with energy efficiency in mind, using sustainable materials and processes that minimise waste. Carbon capture and storage (CCS) technologies are seeing increased adoption, trapping emissions before they reach the atmosphere.

Moreover, the concept of a circular economy is gaining traction. Waste is viewed as a resource, rather than being discarded. By-products from one industry become inputs for another. For instance, the ash residue from coal plants, rich in minerals, is being used in road construction and other sectors. The rise of Industry 4.0, marked by the Internet of Things (IoT), artificial intelligence, and big data analytics, enables factories to monitor emissions in real-time, allowing them to tweak processes to minimize their carbon footprint.

Conclusion

Understanding factory-induced air pollution is similar to traversing a complex mosaic of history, science, economics, and ethics. While the challenges posed by decades of industrial activity are daunting, the collective human endeavour points towards a future that harmonises progress with sustainability. Oizom, at the forefront of this paradigm shift, provides comprehensive solutions that empower industries to monitor, assess, and act. The path to industrial sustainability becomes clearer with real-time data, cutting-edge technology, and a commitment to a greener future.

FAQs

Burning fossil fuels, chemical emissions, toxic gases, and particulate matter are the key sources.

Yes, by providing real-time data to detect, control, and prevent excess emissions.

They track pollutants against standards, generate reports, and support regulatory compliance.