In Jurassic Park, scientists revive prehistoric creatures from fossils buried deep underground. They were researched for their presence on the earth, yet they wind up causing death and damage. Similarly, when we extract oil and gas from the Earth, we harness these ancient minerals as fuels, but using them comes with various adverse effects, including air pollution. Despite fast advances in renewable energy technology, oil and gas accounted for more than half of worldwide energy use.

Furthermore, horizontal drilling combined with hydraulic fracturing to access gas formations has enhanced oil and gas production. This increase in output has resulted in balanced development in oil and gas transportation, processing and refining, agricultural and manufacturing applications, and energy exports (Allison & Mandler, 2018). However, the recent oil and gas production growth has prompted long-standing concerns about its environmental impact.

Although many natural activities (volcanoes, fire, etc.) emit various pollutants into the atmosphere, anthropogenic activities are the primary source of environmental air pollution. Furthermore, the oil and gas industry, which has become a vital resource for modern living, emits many greenhouse gasses, toxic gasses, most of which are methane. They directly harm humans as well as the environment. Published in the journal Environmental Research: Health , the study found that air pollution from the oil and gas sector in the United States has substantial adverse impacts on air quality, human health, and health costs.

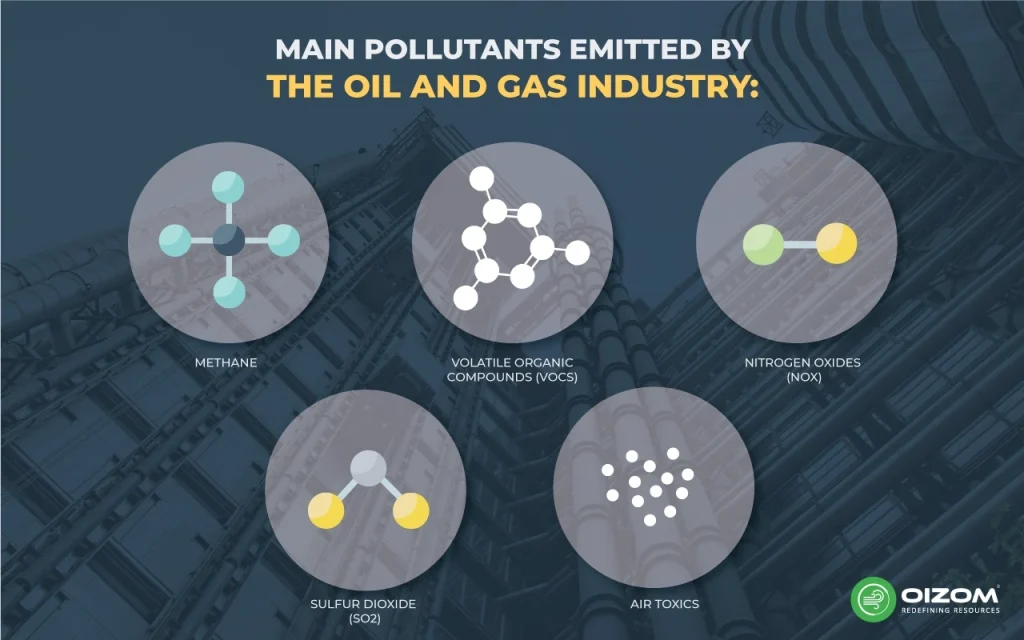

Main Pollutants Emitted by the Oil and Gas Industry:

All commonly used combustible fuels produce hazardous gasses and particles when burned to generate energy. Fixed resources, such as oil and gas fields, refineries, and gas processing units, are smaller than those derived from burning fuels. However, they can have serious local consequences (Allison & Mandler, Air Quality Impacts of Oil and Gas, 2018).

Air toxicants associated with oil and gas can be released during oil exploration, production, refining and processing, and combustion, and these toxicants contribute to climate change. These gases include methane (CH4), nitrogen oxide (NOx), sulfur dioxide (SO2), and high amounts of volatile organic compounds (VOCs), which contribute to the development of hazardous ozone in the lower atmosphere (Butler & Fekete, 2005).

This blog contains general information about the most frequent air contaminants linked with oil and gas extraction. This includes:

Methane

Methane (CH4) is the major component of natural gas and is strongly tied to climate change. (Valuable hydrocarbons such as ethane, propane, butane, and pentanes are commonly found in natural gas and are separated during processing.) Over 20 years, methane is 86 times more potent as a greenhouse gas than carbon dioxide. Natural gas is odourless when first produced; however, methyl mercaptan is added later to odourize the gas and detect leaks.

Volatile Organic Compounds (VOCs)

Volatile Organic Compounds (VOCs) are a group of carbon-containing compounds that quickly convert into gases or vapors and become airborne (volatilize). VOCs can react with nitrogen oxides and sunlight to produce ground-level ozone, which can cause respiratory problems like asthma and impaired lung function.

Benzene, toluene, ethylbenzene, and xylene are the most common volatile organic compounds connected with oil and gas development. These molecules, known as BTEX chemicals, are linked to central nervous system, neurological, and reproductive effects. Benzene is a known carcinogen; ethylbenzene and xylene can induce respiratory issues.

Nitrogen Oxides (NOx)

Nitrogen oxides (NOx) are a series of gases produced by the combustion of fossil fuels, resulting in a chemical interaction between nitrogen (which occurs naturally in the atmosphere) and oxygen. NOx is produced in oil and gas production during flaring activities and when fuel is consumed to power machinery such as compressor engines and other heavy equipment. NOx reacts with VOCs in the presence of sunlight to generate ground-level ozone. NOx can cause eye, nose, and throat irritation, respiratory issues, cardiac disorders, and lung damage.

Sulfur Dioxide (SO2)

Sulfur dioxide (SO2) is a colorless gas emitting pungent odour. It is created by the combustion of sulfur-containing fossil fuels (such as oil, natural gas, and coal). SO2 emissions may occur during natural gas flaring or when fossil fuels are consumed to power pumpjack, compressor engines, and other equipment and vehicles at oil and gas operations. Hazardous gas processing plants also release sulfur dioxide. Along with NOx, SO2 is a major component of acid rain.

Air Toxics

The US Environmental Protection Agency regulates criteria pollutants connected with oil and gas under the Clean Air Act.

- Ozone (O3) is formed when volatile organic molecules and nitrogen oxides react with sunlight. When encountered at ground level, ozone is known as smog, and it can cause or worsen respiratory conditions, including asthma and emphysema.

- According to a health impact analysis, the oil and gas industry’s ozone pollution causes 750,000 summertime asthma attacks in children and 2,600 asthma and respiratory emergency room visits nationwide.

- Particulate Matter (PM) comprises microscopic particles suspended in the air that slowly settle to the earth. Particulate matter is measured as PM10, which are microscopic particles with a diameter of ten micrometers or less, or as PM2.5, which are even finer particles. The most prevalent PM sources in oil and gas operations include dust or soil in the air during site or facility construction, traffic, and diesel exhaust from cars and machinery. PM may also be emitted during venting and flaring operations.

Stages of Oil and Gas Operations Contributing to Air Pollution:

Oil refineries process crude oil into a wide range of products, like gasoline, diesel fuel, kerosene, jet fuel, asphalt, and liquefied petroleum gas, all generating pollutants from several sources necessitating many processes that produce a variety of pollutants, both during regular operations and after accidents. For example, refinery leaks, flames, and excessive emissions emit dangerous air pollutants or toxicants known or suspected of causing cancer and congenital defects and negatively influencing the ecosystem. In addition, defective valves and pumps emit fugitive VOCs in this area.

Natural gas processing poses fewer air pollution problems, although some factories that handle hydrogen sulfide, a poisonous, corrosive, and combustible gas, are classified as toxic release sites. The EPA’s Compilation of Air Pollutant Emission Factors summarizes the various refinery and processing plant operations and their associated emissions.

There are numerous ways to reduce refinery emissions, including better furnace efficiency, leak detection and control, gas recycling, reduced flaring and venting, scrubbers, and catalytic reactors. Between 1990 and 2013, refinery emissions of air toxics and VOCs reduced by 66% and 69%, respectively, despite a 14% increase in crude oil processing.

Health Impacts of Air Pollution from Oil and Gas:

In a peer-reviewed study published in the journal Environmental Research: Health, researchers from Boston University School of Public Health, Institute for the Environment, Environmental Defense Fund, and PSE Healthy Energy assessed the air quality and public health impacts associated with oil and gas production.

This study estimates that regional air pollution from oil and gas production in the U.S. is responsible for 7,500 excess deaths, 410,000 asthma attacks, and 2,200 new cases of asthma each year. All told, health effects due to oil and gas production create annual health costs of $77 billion. Nitrogen oxide, a common pollutant associated with burning natural gas, was the largest contributor to mortality and over 80% of asthma attacks. These health impacts were previously unaccounted for in health impact assessments.

Health effects

- In addition to methane emissions, the oil and gas industry pollutes the atmosphere with many pollutants that endanger human health:

- Volatile Organic Compounds (VOCs) include carcinogens like benzene.

- VOCs and NOx molecules (nitric oxide and nitrogen dioxide) mix with sunlight to form smog, which harms human health and can result in early mortality.

- Hydrogen sulfide gas can make breathing difficult and irritate the eyes and throat. High amounts of exposure are lethal and have killed a number of oil and gas personnel.

Families living with oil and gas development nearby report incidents of:

- asthma,

- respiratory and cardiovascular illnesses,

- autoimmune diseases,

- liver failure,

- cancer,

- headaches,

- nausea,

- sleeplessness, and other ailments.

Environmental Impacts of Air Pollution from Oil and Gas:

Refineries are governed by environmental laws for air, land, and water, as they are a significant source of pollution in their surrounding areas. The refining business is subject to several laws, including the Clean Air Act, Clean Water Act, and Safe Drinking Water Act.

- Petroleum refineries are a major source of hazardous and toxic air pollutants such as BTEX compounds (benzene, toluene, ethylbenzene, and xylene). They are also a major source of criteria air pollutants: particulate matter (PM), nitrogen oxides (NOx), carbon monoxide (CO), hydrogen sulfide (H2S), and sulfur dioxide (SO2).

- Equipment leaks, high-temperature combustion processes, steam and fluid heating, and product transfer can cause air emissions from petroleum refineries. Thousands of pounds of contaminants are released into the environment annually through routine emissions, fugitive releases, accidental releases, and plant upsets. Volatile hydrocarbons and nitrogen oxides contribute to ozone production, a major source of air pollution in the US.

- Refineries can contaminate ground and surface water, posing a significant risk to water quality. Some refineries utilize deep-injection wells to dispose of wastewater, which might end up in aquifers or groundwater. Wastes are controlled under the Safe Drinking Water Act (SDWA). Wastewater in refineries may be highly contaminated, given the number of sources it can contact during the refinery process (such as equipment leaks and spills and the desalting of crude oil).

Did you know Shell has agreed to pay $10 million to resolve air pollution issues at its vast new petrochemical plant in Pennsylvania? This settlement highlights the company’s efforts to address environmental concerns and adhere to air quality regulations. “Unlock the full story: Dive into the details of Shell’s $10 million air pollution settlement by clicking here!”

Mitigation Strategies:

“There are technologies and strategies to reduce refinery emissions by any means, including methane leaks, emissions from compressor stations, or other sources, such as ponds and dehydrators, gas recycling, reduced flaring and venting, scrubbers, and catalytic reactors.” Each of these strategies will affect the levels of different pollutants emitted.”

Reducing methane leaks:

Methane is the primary component of natural gas, and it can leak anywhere along the supply chain, from the wellhead and processing facility to pipelines and distribution lines and finally to the burner of your home’s stove or furnace.

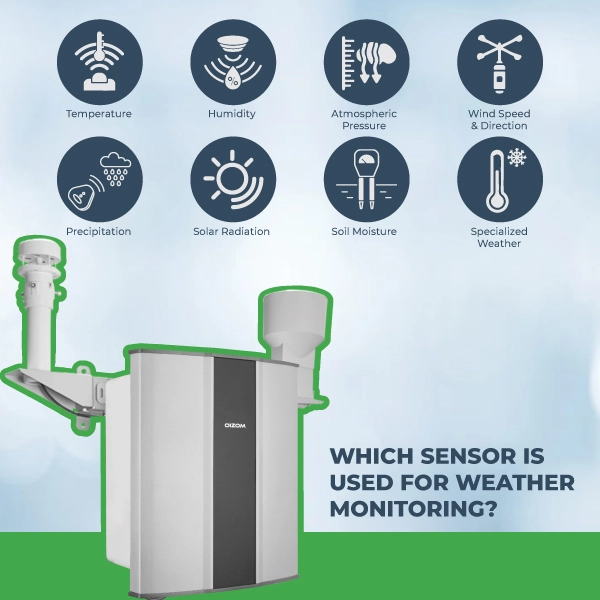

Certain kinds of equipment, such as pneumatic controllers and valves, are known to be extremely leaky. Incomplete gas flaring and venting, which involve scheduled gas releases during well completions or maintenance, also contribute to emissions. With improved monitoring equipment, including ground-based monitoring with Oizom devices such as AQbot, an industrial-grade single parameter, Whether it’s Methane (CH4) or any other toxic gas, industries can now invest in monitoring just that specific parameter, thereby making significant savings.

We know that “bottom-up” estimations based on average emissions components and engineering estimates are too low. Companies are under increasing pressure to use continuous monitoring, implement improved leak detection and repair (LDAR), improve monitoring, reporting, and verification (MRV) methods, and set specific targets for reducing methane emissions. Investors and stockholders are calling for more development.

Controlling VOC emissions:

Oil and gas industries can lower their VOC emissions by employing renewable energy and low-carbon technologies. This can be accomplished in various ways, including encouraging equipment electrification and researching alternate energy options for extraction and refining processes. As the power plant is typically the largest point-source emitter of carbon dioxide in a refinery, there is a strong possibility that newer installations could benefit more from utilizing low-carbon power sources, such as solar or wind energy. The temperature of a concentrated solar power system (CSP) can reach temperatures of 60°C to 250°C. In some cases, as high as 400°C, There is a possibility that in the future, CSP systems may be directly coupled with carbon capture and storage (CCS) units to reduce the amount of carbon dioxide that is emitted by utility systems. As a practical matter, however, it is difficult to integrate such technologies in refineries efficiently and effectively.

Reducing flaring:

Flares can reduce VOC and methane emissions into the atmosphere through controlled gas combustion. The most effective strategy to reduce routine flaring would be to develop new combustion technologies that replace traditional flaring with more efficient alternatives. A systematic study assessed whether dynamic simulation and optimization may be used during chemical plant turnarounds (start-up, shutdown, and upset) to reduce industrial flaring. Establishing a sufficient and practical flare gas recovery system to reduce flare gas emissions during abnormal operations is critical.

Improving energy efficiency:

Energy use affects everyone today, from businesses to individual customers and those at the heart of our political infrastructure. A shift toward higher energy efficiency is required at all levels and sectors to ensure we can protect the world we live and work in.

- Stop flaring, and the usage of related gases: The flaring of related gasses during the oil production process contributes significantly to greenhouse gas emissions. Finding alternate solutions for related gas is critical to improving energy efficiency in corporate operations so that flaring is no longer a regular practice. This could include selling related gas to local companies or turning it into liquefied natural gas.

A focused operating strategy: There are numerous approaches for oil and gas companies to focus their operations on lowering energy use. There are numerous ways to make operations more efficient, including conducting frequent energy audits, upgrading equipment to more innovative and efficient solutions, and implementing long-term action plans to control energy consumption better.

Strengthening regulations and enforcement:

Governments and regulatory bodies must work together to establish oil and gas industry emission guidelines. Investment in clean technologies and practices can be encouraged by enforcing extensive rules and monitoring systems and enforcing fines for noncompliance to encourage businesses to adopt them. The EPA has proposed a plan to significantly reduce the quantity of methane generated by new and current oil and gas sources. To meet the new requirements, states would be required to reduce methane emissions from hundreds of thousands of existing sources across the country for the first time and extend and strengthen existing requirements for new, modified, and reconstructed sources of oil and natural gas.

Conclusion:

Finally, Pollution from oil and gas production significantly impacts human health and climate change. Reducing production emissions has significant benefits, including enhanced public health through reduced exposure to ozone, SOx, and NOx, and climate change mitigation through methane reduction. This blog gives a comprehensive insight into the air pollution caused by the oil and gas industry.

The oil and industry sectors can be integrated into the new process using new technology and procedures. First, leak identification and control are critical for reducing air pollution and minimizing environmental impact. Sector participants should implement process control systems to reduce downtime, maintenance costs, and processing times while increasing resource efficiency and emission control. Detecting and reducing emissions requires continuous monitoring; low-cost air sensors, widely used worldwide, are an essential tool.

Therefore, oil and natural gas companies should increase emission control in production areas at the beginning of their strategies to meet the changing demand.

To learn more about how Oizom’s air quality monitoring systems can be tailored to meet your demand for oil and gas industry emissions. The path to industrial sustainability becomes clearer with real-time accurate data, cutting-edge technology, and a commitment to a greener future.

FAQs

Oil significantly impacts air pollution by emitting CO2, SO2, NOx, particulate matter, and VOCs. These emissions are linked to climate change, smog, acid rain, and health issues.

Natural gas produces less air pollution than oil, emitting fewer CO2, NOx, and SO2. However, methane leaks from natural gas can impact its overall environmental footprint.

The oil industry is a major polluter due to emissions from extracting, refining, and burning oil. While highly impactful, other industries like coal and chemical manufacturing also contribute significantly to environmental pollution.