Monitoring the noise level at ArcelorMittal’s Steel plant in India with AQBot

Monitoring the noise level at ArcelorMittal’s Steel plant in India with AQBot

Our client, ArcelorMittal, installed AQBot Noise, which is a reliable noise monitoring system capable of providing real-time, accurate data and detecting even minor sound-level fluctuations. This device was selected for its exceptional data accuracy, even in harsh weather conditions.

Odisha, India

February 2024

Industrial EHS

Arcelor Mittal

AQBot Noise

Industrial Monitoring

Odisha, India

February 2024

Industrial EHS

Arcelor Mittal

AQBot Noise

Industrial Monitoring

Our Client

Our client, ArcelorMittal, is one of the world’s largest steel manufacturing companies. It has a significant presence in various countries, including India. The company manufactures a wide range of steel products, including flat steel, long products, and specialty steels. The company also invests in research and development to develop innovative steel products and improve its manufacturing processes. ArcelorMittal is also involved in iron ore and metallurgical coal mining, ensuring a reliable supply of raw materials for its steelmaking operations.

The Challenge

Steel plants generate excessive noise that affects the workers’ health and disturbs the nearby community. At ArcelorMittal manufacturing plant, Barbil, noise levels from their manufacturing operations exceeded regulatory limits and impacted the work environment. To address this issue, the company prioritized accurately measuring noise levels and implementing appropriate mitigation measures. They sought a reliable noise monitoring system capable of providing real-time, accurate data and detecting even minor sound-level fluctuations. Ensuring compliance with noise emission regulations was a top priority for ArcelorMittal, requiring a comprehensive solution that could generate detailed daily noise profiles, including peak and minimum levels.

The Solution

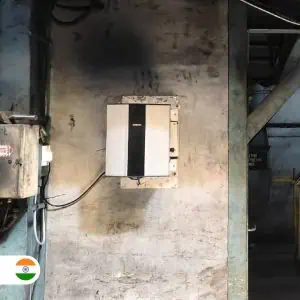

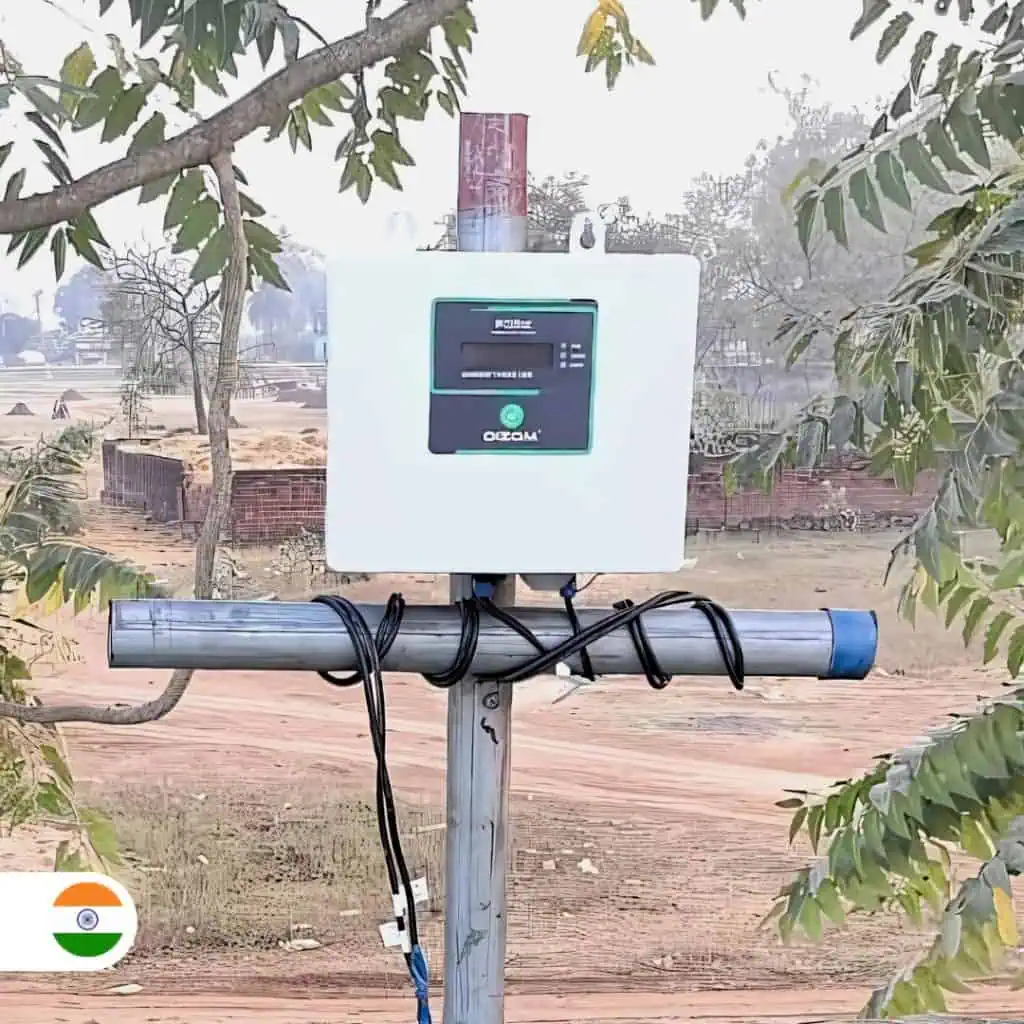

After carefully evaluating available solutions, the AQBot system was selected to meet rigorous technical specifications. Our partner, Enuvos Solutions, installed the AQBot noise monitoring system to facilitate real-time noise level monitoring. This device was selected for its exceptional data accuracy, even in harsh weather conditions, and its compatibility with various communication protocols for seamless integration. The devices have a display that allows workers to check data in real-time and take necessary corrective actions if noise levels exceed the permissible limit.

The Result

The installation of AQBot Noise empowered the client to obtain accurate data on noise generated during manufacturing processes. It is capable of capturing even the slightest fluctuations in noise levels, ensuring accurate measurements. AQBot Noise is an ideal solution, equipped with advanced capabilities to precisely measure and report key sound metrics such as equivalent continuous sound level (Leq), maximum sound level (Lmax), and minimum sound level (Lmin). This comprehensive functionality meets their requirements for detailed noise analysis and ensures compliance with noise monitoring standards.

Oizom’s environmental monitoring platform, Envizom, helps them to get detailed data by generating daily reports on noise levels, enabling informed decision-making to optimize operations and mitigate environmental impact. Using this software, they are able to set alerts that are triggered when noise levels surpass predefined thresholds. They get these alerts via email or SMS to ensure timely response and intervention.

About Oizom

Oizom is a company specializing in environmental monitoring solutions. They offer products to monitor air quality, weather conditions, and other environmental factors. Utilizing advanced sensor technology and data analytics, Oizom aims to provide actionable insights for urban planning, industrial compliance, and community awareness. Their solutions can be applied in various sectors including government, industries, and community initiatives.

Do you have a specific requirement?

Schedule a call with our expert team and get the right solution

for your project.