Summary

Tunnels and parking spaces often feel stuffy, and that’s no coincidence. These enclosed spaces trap harmful pollutants like carbon monoxide (CO), nitrogen dioxide (NO₂), particulate matter (PM), and VOCs due to limited ventilation and constant vehicle movement. This blog breaks down why real-time air quality monitoring in such areas is crucial, not just for compliance, but for health and safety.

It covers key pollutants, their health risks, and how advanced technologies like Oizom’s electrochemical and laser-based sensors provide accurate, real-time insights. From smart ventilation triggers to IoT-powered alerts and predictive maintenance, today’s monitoring systems are smarter and more reliable than ever.

You’ll also learn the difference between tunnel and parking air dynamics, get practical tips on sensor placement and calibration, and explore future trends like AI and SCADA integration. In short, clean air shouldn’t stop at the surface, smart monitoring makes it possible below ground too.

Air Quality Monitoring in Tunnels & Parking

Ever walked into a tunnel or parking spaces and noticed the air feels heavier? That’s not just discomfort, it’s a buildup of pollutants like carbon monoxide (CO), nitrogen dioxide (NO₂), and fine particulate matter (PM2.5). In enclosed environments, vehicle emissions can accumulate rapidly, especially when ventilation is limited or poorly managed.

These confined zones pose unique challenges for air quality management. Unlike open spaces, pollutants don’t disperse easily, making real-time monitoring essential for ensuring safe and breathable air. Without accurate data, ventilation systems can’t respond effectively, leading to prolonged exposure and potential health risks.

Advancements in sensor technology now make it possible to track air quality in real time, detect harmful spikes, and maintain regulatory compliance. From detecting gas concentrations to controlling ventilation dynamically, monitoring systems play a key role in improving air safety and operational efficiency.

Air quality in tunnels and parking areas isn’t just an environmental concern. It’s a matter of health, safety, and smart infrastructure planning.

Why Monitoring Air Quality in Enclosed Spaces Matters

Tunnels and underground parking structures present a unique air quality challenge. Unlike open spaces, these enclosed environments restrict the natural dispersion of pollutants. As a result, gases and dust like carbon monoxide (CO), nitrogen dioxide (NO₂), particulate matter (PM2.5, PM10), and volatile organic compounds (VOCs) can quickly accumulate, especially during periods of high traffic or poor ventilation.

These pollutants pose significant health risks. CO interferes with oxygen transport in the bloodstream, potentially causing fatigue, dizziness, or even loss of consciousness at high concentrations. NO₂ is a strong respiratory irritant, particularly harmful to individuals with asthma or pre-existing lung conditions. PM2.5 can penetrate deep into the lungs and bloodstream, increasing the risk of cardiovascular and respiratory diseases. VOCs, often emitted from fuel vapors or cleaning agents, can trigger headaches, nausea, and long-term organ damage.

What makes these risks even more concerning is the limited airflow in such settings. Without real-time monitoring, pollutant buildup often goes unnoticed until it becomes dangerous. Even well-designed ventilation systems may fall short without data to guide their operation.

A study from a European transit tunnel revealed that CO levels regularly exceeded safety thresholds during peak traffic, despite active ventilation. This underscores the need for continuous, sensor-based air quality monitoring to ensure timely interventions.

Monitoring isn’t just about meeting compliance standards; it’s about protecting the people who work, commute, and spend time in these spaces. By using accurate, real-time data, operators can take proactive steps to maintain healthy air and prevent avoidable exposure.

Key Pollutants in Tunnels and Parking Facilities

Enclosed environments like tunnels and parking facilities create a hotspot for vehicle-related pollutants. With limited ventilation and constant traffic, certain pollutants become particularly problematic, posing both health and compliance risks.

Carbon Monoxide (CO)

CO is produced from incomplete combustion in engines & it is colorless and odorless, making it especially dangerous. It binds with hemoglobin more effectively than oxygen, reducing the body’s ability to transport oxygen. High concentrations can cause dizziness, confusion, and, in extreme cases, unconsciousness. Until recently, tunnel ventilation systems were mainly triggered by high levels of carbon monoxide (CO), nitrogen oxides (NO), or low visibility inside the tunnel. But today, most petrol vehicles have catalytic converters that greatly reduce CO emissions, and diesel engines naturally produce low CO levels. Because of this, CO levels in road tunnels now rarely reach the point needed to turn on the ventilation system.

Nitrogen Dioxide (NO₂)

Nitrogen dioxide (NO₂) is a harmful gas produced during high-temperature combustion, making it a key concern in enclosed traffic areas like tunnels. Even at low levels, NO₂ can irritate the lungs, worsen asthma, and reduce breathing capacity. Long-term exposure is linked to chronic respiratory diseases.

In tunnels, NO₂ concentrations are often much higher than on open roads because there’s limited airflow to disperse pollutants. Since vehicle cabin air is constantly exchanged with tunnel air, passengers inside vehicles can also be exposed to higher NO₂ levels.

Short-term exposure to NO₂, especially at levels commonly found in tunnels (up to 500 ppb), can lead to increased airway sensitivity, reduced lung function, and higher inflammation levels in the blood, even after just 30 minutes.

While nitrogen monoxide (NO) is also present in tunnels, it’s generally not as harmful on its own. In the past, NO was used to estimate NO₂ levels because it reacts with oxygen to form NO₂. However, newer research shows that relying only on NO to estimate NO₂ may not always give accurate results, highlighting the need to directly monitor NO₂ levels in tunnel air.

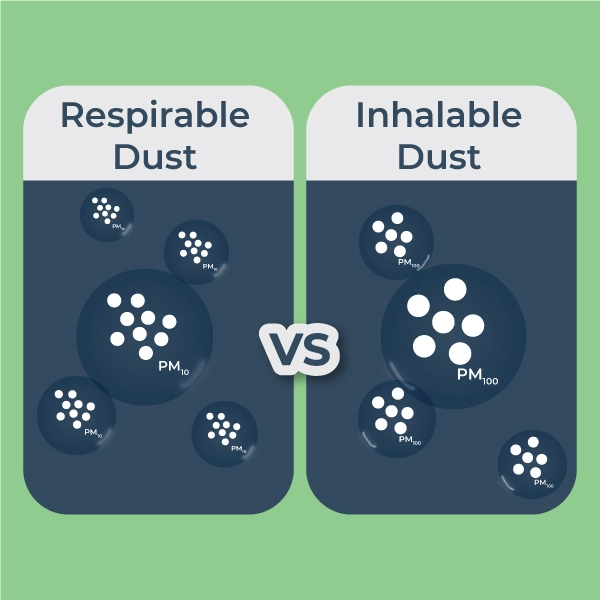

Particulate Matter (PM2.5, PM10)

Parking garages are part of everyday life, whether you’re out shopping, commuting to work, or visiting the city. While they’re convenient, particulate matter also come with hidden health risks. These enclosed or semi-enclosed spaces often act as hotspots for air pollution, especially particulate matter (PM).

Due to frequent vehicle movement and limited airflow, pollutants like PM10, carbon monoxide (CO), volatile organic compounds (VOCs), and polycyclic aromatic hydrocarbons (PAHs) can build up quickly. Studies have found that underground and semi-enclosed parking garages often have higher PM10 levels than outdoor spaces. In fact, research at hospitals and college parking areas showed that pollution levels, especially CO and PAHs, were significantly higher on weekdays due to increased traffic.

Another study from Wuhan, China, reported that PM10 concentrations at the exit of an underground parking garage exceeded indoor air quality standards, pointing to poor ventilation and constant pollution buildup.

Tire wear particles (TWPs) are also a growing concern. In areas like rotational sections of parking garages, where vehicles turn sharply, the slip angle increases, leading to more tire wear. While it’s likely that TWPs are present in indoor garages, very few studies have explored this in detail.

These findings highlight the importance of air quality monitoring in parking facilities to ensure health and safety for both short-term visitors and regular users.

Volatile Organic Compounds (VOCs)

Volatile Organic Compounds (VOCs) are carbon-based chemicals that easily turn into gases at room temperature. In enclosed spaces like road tunnels and parking garages, VOC levels can rise quickly due to limited ventilation and continuous vehicle activity.

One of the main sources of VOCs in urban areas is vehicular exhaust, especially in car parking facilities. These emissions release a variety of toxic chemicals into the air. Some VOCs are carcinogenic, meaning they can cause cancer, while others are non-carcinogenic but still harmful to human health and the environment.

Where Do VOCs Come From?

In tunnels and parking areas, VOCs can be released from:

- Vehicle exhaust (particularly from unburned fuel)

- Fuel evaporation during idling or refueling

- Oil leaks and engine lubricants

- Cleaning products, solvents, and paints

- Plastic, rubber, and interior materials inside vehicles

Common VOCs Found

Some of the most commonly detected VOCs include:

- Benzene

- Toluene

- Ethylbenzene

- Xylene (together known as BTEX)

- Formaldehyde

Many of these compounds are classified as toxic or hazardous, and long-term exposure can lead to serious health problems. This makes it essential to monitor VOC levels in enclosed traffic zones to ensure a safe environment for workers and the public.

If you’re dealing with BTEX compounds (benzene, toluene, ethylbenzene, and xylene), you know how important it is to monitor them accurately. These volatile compounds are often present in multi-level parking and tunnels and can pose serious health and environmental risks if left unchecked.

To address this, Oizom has integrated a dedicated BTEX sensor into its range of environmental monitoring devices. Known for their modular design and real-time data capabilities, Oizom devices now offer reliable detection of BTEX compounds, helping authorities and researchers gain deeper insights into enclosed air quality and take timely action where needed.

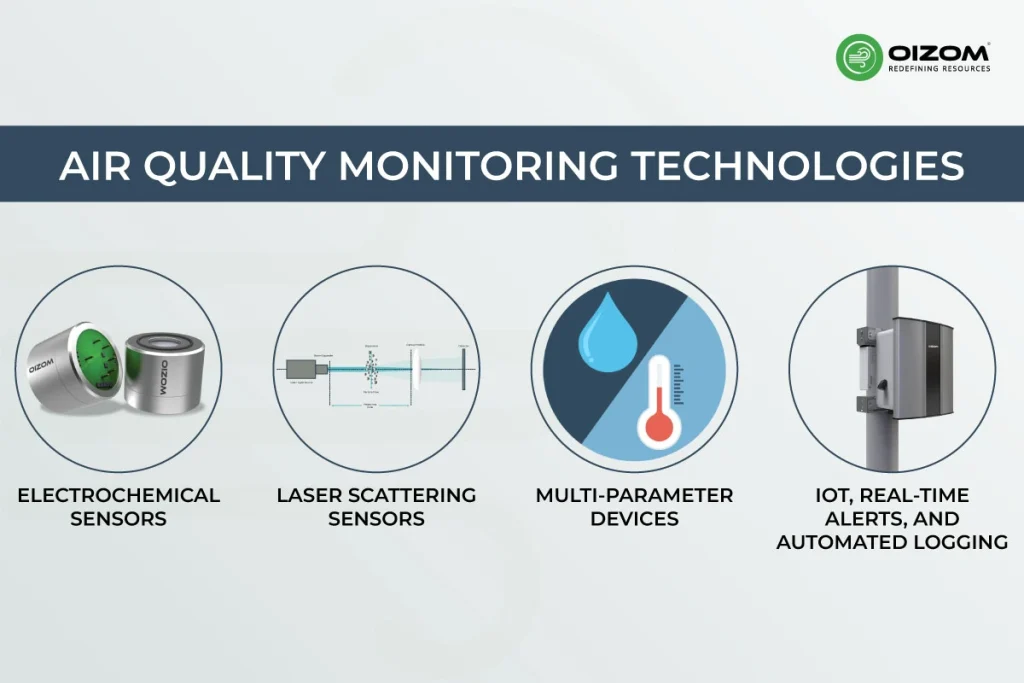

Air Quality Monitoring Technologies

Monitoring air quality in tunnels and parking garages requires accurate, responsive, and durable technology. These spaces demand sensors that can function reliably in confined, pollutant-heavy conditions. Thankfully, today’s advancements make real-time tunnel air monitoring more effective than ever.

Since tunnels are almost completely enclosed, air pollution can build up quickly inside them. While the acceptable pollution limits are usually higher in tunnels than in open air, because people are exposed for shorter periods, it’s still important to monitor the air to make sure these limits aren’t crossed.

Electrochemical sensors

Electrochemical sensors are widely used for detecting toxic gases like carbon monoxide (CO), nitrogen dioxide (NO₂), and sulfur dioxide (SO₂). These sensors work by generating an electrical signal when a target gas interacts with an electrode. They offer high sensitivity and are ideal for real-time gas monitoring in enclosed environments.

Let me share with you the oizom sensor working principle.

Oizom provides a range of Carbon Monoxide (CO), Nitrogen Dioxide (NO₂), and Sulfur Dioxide (SO₂) sensor modules to monitor varying CO, NO₂, and SO₂ levels based on your needs. Our sensors accurately measure all three parameters in ambient conditions, detecting concentrations in ppb/ppm. This sensor monitors polluting gases in real time. This sensor is integrated into a metal casing and ultra-low-noise support electronics, making it compact and reliable. This allows accurate gas detection even at very low concentrations in the atmosphere. This sensor works on the Electrochemical working principle to measure environmental air quality.

This sensor undergoes calibration using standard gases and tools to ensure high sensitivity and accuracy. Each gas sensor is calibrated with zero and span checks in a controlled lab, following Section 12.2 of the USEPA Quality Assurance Handbook for Air Pollution Measurement Systems Volume II. Calibration is done using NIST-traceable gas standards for reliable performance.

The CO, NO₂, and SO₂ sensor module is integrated into outdoor air quality monitoring systems like Polludrone, AQBot, Odosense, and Pollusense. It is ideal for applications in parking spaces and tunnels.

Laser scattering sensors

For particulate matter (PM2.5, PM10), laser scattering sensors are the go-to solution. These sensors use a laser beam to detect light reflected by particles in the air, providing precise measurements even at low concentrations. Their quick response time makes them suitable for dynamic traffic conditions inside tunnels and garages.

This question might arise whenever you monitor particulate matter. Why are my readings too high in the morning?” Likely due to fog or high humidity. If your sensor doesn’t have a heated inlet, it might be picking up water droplets instead of real dust.

Worried about humidity messing with your dust data? You’re not alone; high relative humidity (especially above 80%) is a known troublemaker for PM sensors using laser scattering. When RH hits close to 100%, things like fog or mist can fool the sensors, causing water droplets to be counted as dust particles. That means inflated PM readings and misleading reports.

But with Oizom Dustroid, you can leave those worries behind. It’s equipped with a heated inlet that dries the air before it reaches the sensor. No more confusion between moisture and real dust particles, just accurate, reliable data, no matter the weather. Monsoon humidity, or early morning mist, Dustroid has it covered.

Multi-parameter devices

Modern monitoring solutions often combine multiple sensors into a single device. These multi-parameter units can simultaneously measure gases, PM, temperature, and humidity, offering a comprehensive picture of the air quality. This is especially useful in complex environments like tunnels where multiple pollutants coexist.

IoT, real-time alerts, and automated logging

With IoT-enabled systems, data can be logged, visualized, and analyzed remotely. Real-time alerts help operators take immediate action, such as increasing ventilation or restricting vehicle entry, before conditions become unsafe. Historical data logging also supports long-term air quality assessments and regulatory compliance.

A relevant example is the Skanska tunnel construction project, where real-time monitoring was integrated to enhance both worker safety and operational efficiency. The system helped detect pollution spikes early and provided historical data that supported air quality assessments during different construction phases. View case study

Tunnel vs Parking Monitoring – What’s Different?

While both tunnels and parking garages are enclosed spaces, their air quality monitoring needs differ due to how pollutants behave and how air is managed in each setting.

Ventilation Systems

Tunnels typically use dynamic ventilation systems, which adjust airflow based on real-time pollutant levels and traffic conditions. Jet fans or longitudinal ventilation setups help move polluted air out quickly. In contrast, parking garages rely on mechanical ventilation, often operating at set intervals or speeds, regardless of actual air quality. This makes real-time monitoring even more critical in parking spaces to trigger ventilation only when needed, improving both efficiency and energy use.

Pollutant Load Behavior

Tunnels experience a continuous flow of traffic, leading to a steady emission of gases like CO and NO₂. The airflow is generally unidirectional, which helps move pollutants toward exhaust points. In parking spaces, pollution tends to accumulate and stagnate, especially in underground or poorly ventilated sections. Vehicle idling, frequent starts and stops, and limited dispersion contribute to higher static concentrations, particularly of VOCs and PM.

Sensor Placement & Calibration

In tunnels, sensors are often placed at intervals along the bore, near ventilation control points, and portals. In parking spaces, placement focuses on areas with poor airflow, such as corners, ramps, and low ceilings. Regular calibration and maintenance are crucial in both setups to ensure accurate readings, especially in extreme conditions with temperature fluctuations, dust, and humidity.

A practical example can be seen in the Abdul Aziz Tunnel in Mecca, where Oizom’s Polludrone was deployed to assess pollutant levels and optimize tunnel ventilation. The project highlighted how proper sensor placement and a structured calibration schedule can enhance data accuracy and support effective air quality management. Read the case study.

Understanding these differences is key to deploying effective air quality monitoring systems that meet safety and compliance needs in each environment.

Compliance & Standards

Air quality monitoring in tunnels and underground parking structures isn’t just best practice, it’s a legal and safety requirement in many parts of the world. Various standards and regulations define acceptable exposure limits, sensor performance criteria, and data reporting protocols to protect both public health and worker safety.

Key Standards and Guidelines

Standards like OSHA (Occupational Safety and Health Administration) and NIOSH (National Institute for Occupational Safety and Health) in the U.S. outline permissible exposure limits for gases such as CO, NO₂, and VOCs. In Europe, EN 50545-1 sets clear requirements for gas detection systems in car parks and tunnels, including performance benchmarks for sensor accuracy, lifespan, and alarm settings.

Government Regulations

Many local and national governments have implemented specific mandates for vehicular tunnels and large underground garages. These include requirements for real-time monitoring, ventilation control integration, and emergency alert systems. Compliance is often tied to building permits, environmental approvals, and worker safety certifications.

Importance of Alerts & Data Reporting

Setting accurate alert thresholds is critical to trigger timely ventilation or evacuation actions. For instance, a spike in CO beyond 50 ppm or NO₂ above a certain ppm should prompt immediate intervention. Reliable data logging is equally important for audits, regulatory reporting, and trend analysis. Cloud-based systems with automated logs help maintain transparency and ensure long-term compliance.

Adhering to these standards not only ensures safety but also builds credibility with stakeholders and regulatory bodies, an essential step for any modern infrastructure project.

Design & Deployment Best Practices

Deploying an air quality monitoring system in tunnels or parking facilities isn’t just about choosing the right sensors. It’s also about placing and maintaining them correctly for reliable performance.

Strategic Sensor Placement

Sensors should be installed at key zones, near entry and exit points, mid-sections, and close to ventilation outlets or fans. These locations help capture pollution patterns and ensure timely ventilation responses. In parking, placing sensors near ramps, corners, and low-ventilation areas is crucial to detect stagnant pollutant build-up.

Installation Height

For gases like CO and NO₂, installing sensors at 1.5 to 2 meters height is ideal. This height reflects the average human breathing zone and ensures more accurate exposure readings. Placement should also consider gas density; lighter gases rise, while heavier ones settle lower.

Maintenance & Calibration

Even high-quality sensors require regular calibration to maintain accuracy. Follow the manufacturer’s recommended calibration intervals, typically every 6 to 12 months, and include a preventive maintenance schedule to check for dust, corrosion, or sensor drift.

Redundancy & Backup

To ensure continuous operation, use redundant sensors in critical areas and incorporate backup power systems (like a battery or UPS) to keep monitoring active during outages. This is especially vital in emergency-prone environments like tunnels.

Future Trends & Innovations

As infrastructure gets smarter, so do air quality monitoring systems in tunnels and parking facilities. New technologies are pushing the boundaries of what’s possible, making monitoring not just reactive, but predictive and integrated.

AI for Predictive Maintenance

Artificial Intelligence is transforming sensor maintenance. By analyzing historical data, AI can predict when a sensor is likely to drift or fail, allowing operators to schedule preventive maintenance before issues occur. This reduces downtime and extends device lifespan.

Edge Computing for Real-Time Alerts

Edge computing enables on-site data processing directly within the sensor unit or gateway. This drastically cuts response time by generating real-time alerts without relying on cloud connectivity. It’s especially valuable in emergency scenarios like gas leaks or sudden PM spikes.

Smart Integration with BMS and SCADA

Modern systems now support seamless integration with Building Management Systems (BMS) and SCADA platforms, allowing centralized control of ventilation, alarms, and environmental data. This makes it easier for facility managers to respond to changing air quality conditions automatically.

Green Tunnel Design

Future-ready tunnels combine air quality monitoring, emission control technologies, and renewable energy sources. Solar-powered ventilation, low-emission coatings, and data-driven design are shaping the next generation of sustainable infrastructure.

Conclusion

Air quality monitoring in tunnels and parking structures is no longer optional. It’s a vital part of designing safe, efficient, and compliant infrastructure. With limited ventilation and constant vehicle emissions, pollutants like CO, NO₂, PM, and VOCs can quickly reach hazardous levels if not properly tracked and managed.

The good news? Technology is keeping up. From electrochemical and laser-based sensors to IoT-enabled systems with real-time alerts and historical logging, modern monitoring tools make it easier to detect risks early and respond quickly.

Looking ahead, AI-powered maintenance, edge computing, and integration with smart infrastructure platforms will further improve how we monitor and manage air in confined environments. Future-ready designs will combine data, automation, and sustainability, not just to meet standards, but to build cleaner, healthier spaces for everyone.

Whether you’re planning a tunnel, managing a parking facility, or setting regulatory guidelines, investing in robust air quality monitoring isn’t just about compliance. It’s about creating long-term value and protecting the people who use these spaces every day. Because Tunnels and garages trap more than just vehicles, they trap pollutants too.