World’s Largest Gold Undermine Chooses Oizom’s Dustroid for Dust Monitoring

World’s Largest Gold Undermine Chooses Oizom’s Dustroid for Dust Monitoring

A world-class mining company chose Dustroid to maintain occupational health and safety by dust monitoring in gold undermine.

Carletonville, South Africa

October 2022

Mining And Quarrying

AMS Haden

Dustroid

Dust Monitoring

Our Client

A Guinness World Record holder, our client owns the world’s deepest and richest gold underground mine with an average depth of 2800m-3400m (from the ground level), in South Africa. There are about 4000 miners working every day in the underground mine to excavate over 5400 metric tonnes of rock every day. This mine has at least two gold reefs and the deepest one sizes to one metre thick. They are known for their extraordinary shaft from which the ice is slopped in the underground mine to maintain the temperature and make it bearable from above 60 degrees to somewhere 30-40 degrees. They believe in the safety of the environment and their miners and are affirmed to keep these two motives above everything.

The Challenge

Maintaining good air quality and preventing health hazards for miners became difficult due to heavy dust-laden activities like blasting, crushing, digging, drilling, etc. Additionally, such large and deep undermines have high temperatures comparatively to the ground level. This increases the chances of various health problems. The company came up with a solution for this – using dust monitors. They started using dust monitoring devices to take corrective actions, but the monitors were unable to work accurately in harsh weather conditions like heat and humidity. They needed dust monitoring in gold undermine that could withstand climatic conditions and provide accurate data for them to analyse and take further actions. The monitor needed to be qualified to identify even the smallest parameter of dust particulate as well as needs to be safe to use in underground mines.

The Solution

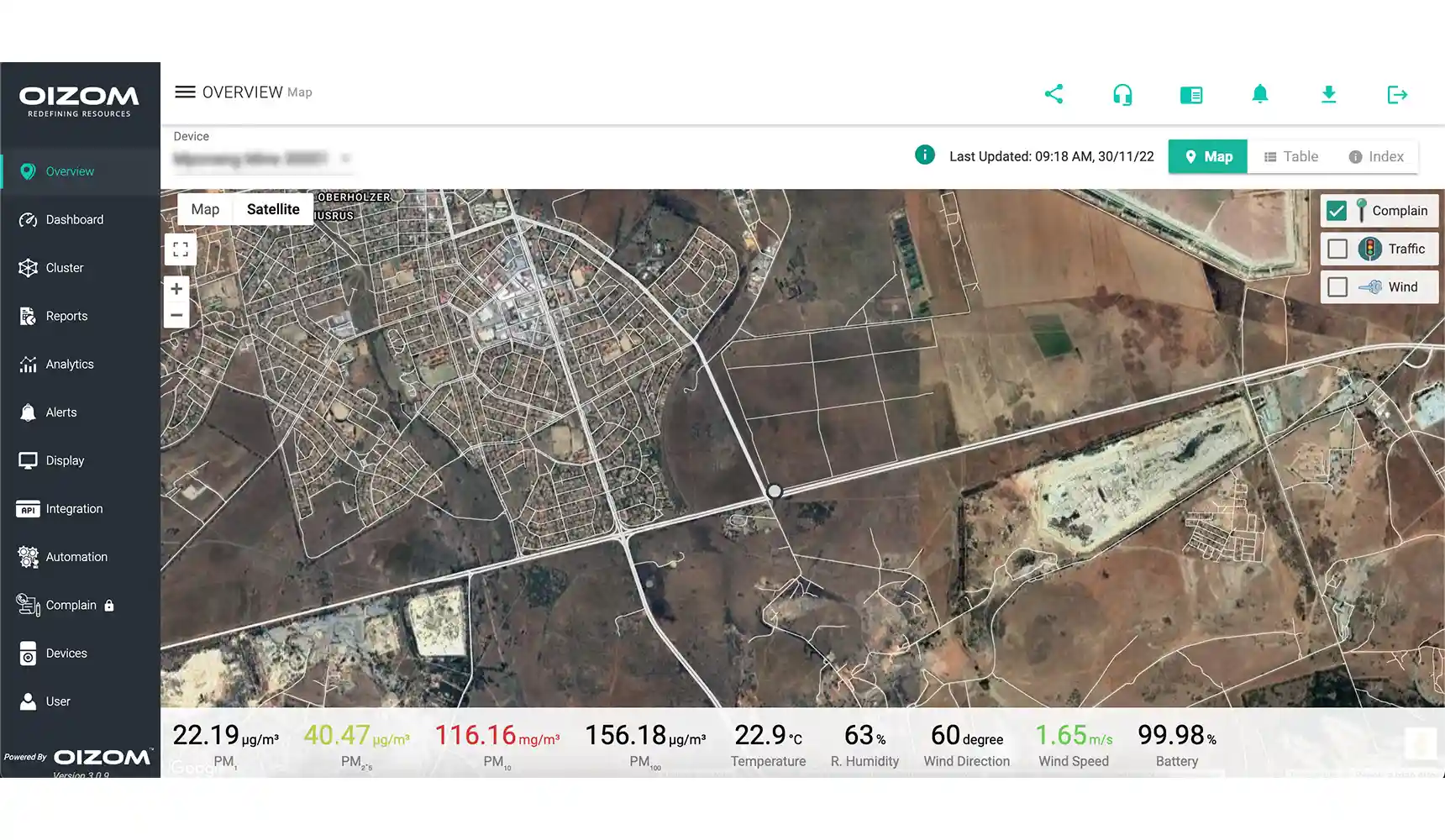

World’s leading underground gold mining company chose Dustroid as an ideal solution to maintain occupational health & safety along with taking care of the environment. As Dustroid can withstand high concentrations of PM up to 30ug/m3, withstand high temperatures underground that exceed up to 40 degrees C on a daily basis and can provide accurate & actionable data insights by monitoring the smallest dust particle, our clients chose to install 35 units of Dustroid in their gold undermine. They can access the data collected by all the units through one software which they can install on any convenient device. These data show data insights segregated by levels of different types of gases found in the dust particles. This way, our clients can take better corrective actions. Additionally, Dustroid also provides automation for dust suppression when the dust level exceeds the limits, which can be extremely useful in underground mining.

The Result

As a result, they were able to take preventive actions to tackle the potential hazard caused by extreme dust by relying on the impeccable accurate data provided by Oizom’s dustroid. Through these actions, the health of their miners is saved from possible health risks like various respiratory and skin diseases. Our client can take corrective actions against toxic air, dust, and humidity through our multi-parameter dust monitoring system – Dustroid.

About Oizom

At Oizom, we engineer solutions for the most challenging environments. Our partnership with a Guinness World Record holder underground gold mining company in South Africa showcases our commitment to occupational health and safety. With the installation of 35 Dustroid units, we’ve enabled real-time, accurate monitoring of dust particles and gases, even in extreme underground conditions. Our technology has been pivotal in protecting miners from potential health risks. Explore how Oizom is redefining safety in mining.

Do you have a specific requirement?

Schedule a call with our expert team and get the right solution

for your project.