Summary

One of the most important factors in maintaining a data center is air quality. Microscopic particles can cause equipment problems, such as rusting components in the data center, reduce component lifespans, and extend downtime. Established standards, such as ASHRAE, ISA-71.04, and ISO cleanliness classifications, define acceptable particle and gas limits. By maintaining these limits, operators can easily manage and contain particulate and gas-related risks. Meeting these standards can be achieved through strategic planning, disciplined operations, and real-time performance monitoring, enabling early detection of compliance violations before they affect performance.

Data Center Air Quality Standards Explained Simply

When people think about what makes up a data center, they usually mention uptime and cooling efficiency, system power redundancy, and cybersecurity. However, establishing a standard for air quality in a data center is not merely an environmental concern; it is an operational requirement. Air quality standards established for a data center specify the acceptable range of indoor atmospheric conditions for a sensitive electronic environment. They take the form of measurable limits for each invisible contaminant and practical guidance to help you protect your equipment, maintain its performance, and deliver the reliability you expect.

What Are Data Center Air Quality Standards?

The Air Quality Standards for Data Centers are guidelines that define acceptable indoor air quality levels. Unlike the Indoor Air Quality (IAQ) standards for occupant comfort, data center air quality standards focus solely on protecting equipment from premature or catastrophic failure caused by airborne contaminants. These risks are primarily driven by particulate and gaseous contamination, with fine particulate matter and corrosive gases posing the most significant threat to data center equipment.

Fine particulate matter accumulation creates a physical barrier between circuit boards. It may also clog airflow paths, causing electronic equipment to operate out of specification and create an unnecessary heat buildup. In addition, gaseous air contaminants, such as sulfur compounds, nitrogen oxides, and chlorine, can corrode metal surfaces on data center printed circuit boards.

A prevalent misconception is that the cleanliness of a data center equates to airborne safety. Air Quality Standards were developed to close this gap and determine the safety of air based on verifiable criteria that apply to electronics rather than based on Air Quality alone It should be noted that while the existence of Air Quality Standards does not eliminate the need for cooling or HVAC design, they do provide an additional avenue for determining what materials enter a cooling/HVAC system.

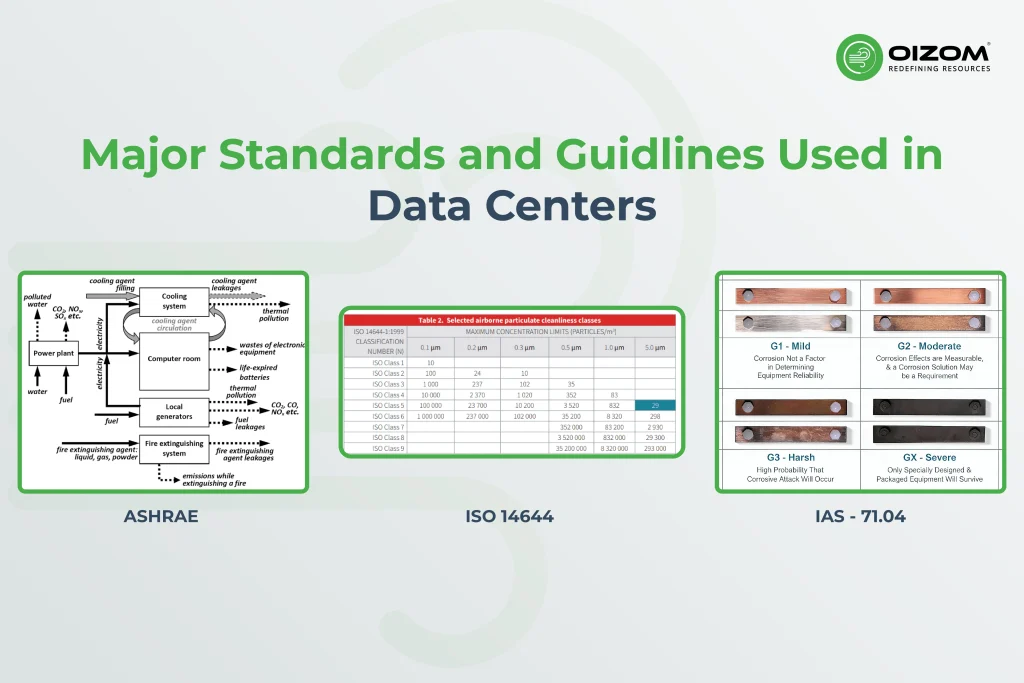

Major Standards and Guidelines Used in Data Centers

A single rule does not determine air quality in data centers; rather, it is defined by multiple standards that address multiple environmental risks. Data center air quality is defined by established standards such as ASHRAE guidelines, ISA-71.04, and ISO cleanliness standards, or equivalent, to gain a complete understanding of “acceptable” air for a data center.

ASHRAE Guidelines for Data Center Air Quality

ASHRAE guidelines form the baseline. They define acceptable temperature and humidity ranges for data processing environments, shaping air quality by reducing risks such as electrostatic discharge, condensation, and accelerated component ageing.

ISA-71.04: Corrosion Severity Standard

ISA-71.04 focuses specifically on corrosion risk caused by gaseous contaminants. It categorizes indoor environments by corrosion severity, helping operators assess whether airborne pollutants could damage electronic components over time.

ISO Cleanliness Standards (When Applicable)

ISO cleanliness standards are selectively applied, mainly where stricter particulate control is required. They define acceptable particle concentrations and are applied when dust and fine particles pose a risk to airflow, cooling efficiency, or sensitive equipment.

Acceptable Air Quality Limits Inside Data Centers

Air quality for electronic devices is determined by how much it affects physical damage, corrosion, and disruption to a device’s operations. The limits on particulate matter, gas contaminants, and environmental conditions like temperature and humidity will determine how much of each is acceptable in a data centre.

Particulate Matter Limits

Particulate matter poses both physical and thermal risks to equipment. The accumulation of fine particles on circuit boards reduces heat sink performance. It impedes airflow, reducing overall cooling efficiency and elevating the equipment’s operating temperature, thereby increasing the failure rate. This is accomplished through filtration, airflow control, and strict housekeeping procedures.

Gaseous Contaminant Thresholds

Gaseous pollutants are difficult to detect and pose a significant threat to equipment. Gaseous contaminants, such as reactive gases (e.g., sulfur compounds, chlorine, and nitrogen oxides), can corrode metal components in electronic devices. Data centres aim to keep these gaseous contaminants at levels considered low in corrosion severity to mitigate the effects of corrosive gases, particularly in urban, industrial, or coastal environments.

Temperature and Humidity as Supporting Standards

Even though temperature and humidity don’t directly contaminate the air, they affect how particles and gases behave. In addition, the impact of particles and gases is amplified by excessively high temperatures, which place additional stress on the system’s components. Maintaining recommended temperature and humidity levels improves air quality, reduces the risk of secondary damage, and extends the equipment’s service life.

Reasons Data Centers Fail to Meet Air Quality Standards

Air quality compliance issues in most data centers arise from misjudging air-related risks during design and operations, not from the ambiguity of data center air quality standards. The most significant location-based issue concerning air quality compliance is during the design phase. Facilities located near industrial sites, urban areas with heavy traffic, and coastal areas will typically experience greater intrusion of particulate matter and corrosive gases. It is often assumed that meeting general indoor air quality standards is sufficient for data centers; however, these standards do not address the specific contamination risks and sensitivity of electronic equipment.

Operationally, most air quality controls will degrade or become less effective due to filter depletion, airflow changes caused by added racks or servers, and the introduction of dirt into controlled areas during maintenance. If the data centre does not continuously monitor changes in airflow patterns, air quality issues can go unnoticed until the data centre’s equipment reliability begins to degrade.

Lastly, this narrow view of air quality creates a disconnect between the premise of environmental control and the practical implementation of equipment protection, a disconnect that becomes apparent only after equipment failures, downtime, or unexpected maintenance costs occur.

Best Practices to Maintain Data Center Air Quality Standards

At the design stage, air quality considerations should be integrated alongside cooling and airflow planning, rather than treated as a secondary or operational concern. It is essential to select appropriate particulate- and gas-phase filtration based on local outdoor air pollution, seal the building envelope to prevent unfiltered air from entering the space, and zone all spaces to reduce contamination during maintenance tasks.

Consistency in operations is critical; regular inspections, filter replacement at least once a month, consistent cleaning processes, and well-defined access protocols help mitigate the introduction and reintroduction of dust into a data center’s environment. Changes in rack density, airflow patterns, or cooling methodology must also be evaluated for their impact on contaminant dispersion within the environment, rather than solely on temperature.

Finally, the monitoring process completes the loop. Continuously or nearly continuously tracking particulate matter and corrosive gas levels enables early detection of failures or declining efficiency.

Role of Air Quality Monitoring Systems in Standards Compliance

Monitoring systems are used to measure actual air quality against established air quality standards, bridging the gap between compliance standards and actual emissions. Monitoring provides empirical data confirming compliance of particulate levels, gas contaminant concentration, and supporting environmental conditions. For example, an organization may find that it references multiple regulations simultaneously, including ASHRAE regulations (environmental control) and ISA-71.04 (Corrosion Risk).

In addition, early warning of this change in condition can be achieved by monitoring the organization’s air quality. Monitoring allows the operator to take immediate action to prevent equipment damage and detect an increase in particulate matter immediately after the initial rise caused by a filter malfunction or contamination during maintenance. Likewise, monitoring provides operators with knowledge of increasing levels of corrosive gases in the air, potentially due to deteriorating outdoor air quality or reduced ventilation performance from reduced airflow.

Therefore, monitoring supports the operator’s ability to make better decisions about the use of filtration systems, validate HVAC system performance, and modify facility operational procedures based on actual air conditions, rather than relying on assumptions.

Evolving Standards and Future Expectations for Data Centers

Data centers are continually evolving as they become more distributed, more densely packed, and more crucial to the functioning of digital infrastructure worldwide. The expansion of monitoring technology, combined with regulatory and industry demands for greater transparency and resilience, will play an integral role in shaping how air quality standards evolve.

From a technological perspective, advances in sensor accuracy, real-time analytics, and integrated monitoring systems have significantly impacted how organisations monitor and manage air quality. Continuous, accurate air quality monitoring is essential for data centers to meet ASHRAE 62.1 and general workplace and public health regulations.

Furthermore, as the demand for data centre services continues to increase, so does the regulatory scrutiny of the environmental impact of these facilities. While most regulations have focused on energy consumption, there is growing recognition that these facilities also pose significant environmental and public health risks. As data centres continue to consume energy and become more densely populated, increased regulatory scrutiny will require these operators to establish processes and procedures to identify and mitigate their environmental and public health impacts.

Conclusion

The ASHRAE, ISA-71.04, and ISO standards define appropriate conditions; however, the greatest difficulty in achieving them lies in maintaining consistent environmental conditions. This is especially true in an environment where the expectation to maintain uptime continues to rise while the responsibility for this service expands. Within this framework, air quality monitoring has transitioned from a reactive mitigation strategy to an operational necessity and an unavoidable aspect of business operations.

FAQs

ASHRAE guidelines, ISA-71.04 corrosion standards, and ISO cleanliness standards.

ASHRAE TC 9.9 recommendations for temperature, humidity, and environmental conditions in data processing environments.

Low enough to prevent dust buildup that could block airflow or damage components, often guided by ISO cleanroom classes when needed.

Using real-time sensors and monitoring systems for particles, gases, temperature, and humidity to ensure standards are continuously met.