Summary

- Waste management facilities release a range of pollutants, including dust, odors, VOCs, and H₂S, which can impact workers, nearby communities, and the environment.

- Air quality monitoring systems enable real-time pollutant tracking, supporting facilities in recognizing trends and operational efficiency.

- Monitoring helps in guiding regulatory compliance, ensuring workplace safety, and empowering proactive management of emissions.

- Best practices like strategic sensor placement, regular calibration, and complex data processing improve the system’s performance.

- Generally, financing air quality monitoring is not just about compliance; it improves operational flow, environmental stewardship, and community well-being.

How Air Quality Monitoring Helps Waste Management Facilities?

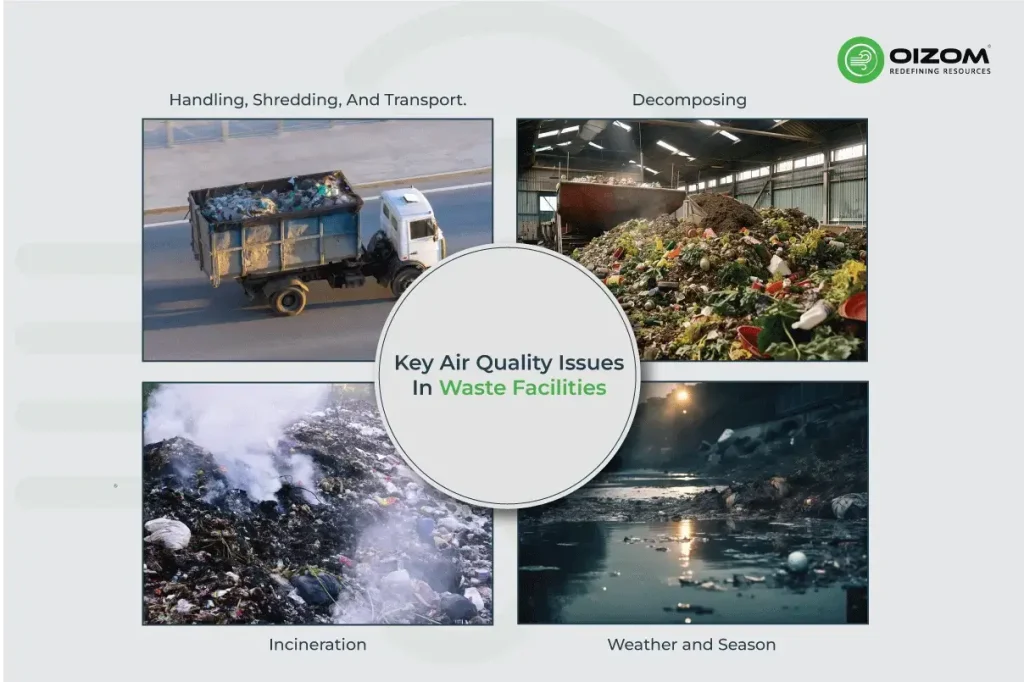

Air pollution is a persistent challenge affecting every primary industry, including the automotive sector. Of these industries, waste management facilities, namely landfills, recycling plants, and waste-to-energy facilities, have specific air quality issues stemming from the varied nature of the waste they process. Dust, odors, and gaseous emissions may occur during processing, decomposition, or incineration and create complex air quality management issues. For example, a municipal landfill may release fine particulate matter and VOCs that impact workers and neighborhoods nearby. Awareness and measured actions are both key to tackling emissions well and keeping waste management operations safe and environmentally sound.

What Are the Main Air Quality Challenges in Waste Management Facilities?

Waste management facilities, including landfills, recycling plants, and waste-to-energy facilities, face many air quality issues that require urgent attention. Emission of particulate matter and dust is a significant issue, repeatedly observed during waste handling, shredding, and transport. These suspended particles, if left uncontrolled, would spread outside the plant and impact surrounding communities, thereby adding to air pollution as a whole.

Odors are also an issue. Plants emit volatile organic compounds (VOCs) and hydrogen sulfide (H₂S) gases while decomposing or processing organic waste. These emissions create a poor working environment and indicate the presence of toxic compounds that require monitoring. For instance, a city landfill in California installed odor monitoring sensors after repeated complaints from nearby residential areas, enabling better operational modifications to reduce emissions.

Besides this, waste treatment plants release nitrogen oxides (NOx), ammonia (NH₃), and other volatile pollutants, particularly from incineration or composting activities. Though the concentration can change as per operational processes, unchecked emissions can have impacts across the environment and regulatory compliance.

Lastly, dust, odor, and gaseous emissions can vary, making it difficult to predict impacts due to weather, season, and load operation, without current information. Such variability points to the need for strong air quality monitoring systems that can monitor continuously and deliver actionable information. By learning about trouble spots and trends, facilities can maximize performance, minimize emissions, and stay in compliance, the precursor to the next section on how monitoring systems operate in waste management.

How Air Quality Monitoring Systems Work in Waste Management?

Air quality monitoring systems create an accurate emissions pattern and air quality trend by continuously monitoring the concentration of pollutants. At a macro level, these systems integrate a set of sensors and data acquisition devices to monitor major pollutants like particulate matter (PM2.5 and PM10), volatile organic compounds (VOCs), hydrogen sulfide (H₂S), ammonia (NH₃), and nitrogen oxides (NOx).

Sensors are generally installed at key locations across the facility, around areas of processing, landfills, or incinerators, to detect air quality fluctuations created by varying operations. They employ technologies such as laser scattering for particulates, electrochemical cells for gases, and photoionization detectors for VOCs. The acquired data is sent in real-time to a centralized monitoring system, where it is processed, visualized, and archived for analysis.

Sophisticated monitoring systems also feature elements such as threshold-based alarms, which alert operators when pollutant concentrations rise above pre-set limits. Systems may also incorporate weather information or operating parameters, enabling operators to discern relationships between operations and emissions. The integration of real-time measurement, automatic alarms, and data display allows facility managers to have ongoing air quality monitoring and inform operational decisions.

Through continuous monitoring of pollutant levels, these systems provide the foundation for proactive air quality management, laying the groundwork for the next section, which explores the key benefits of implementing such monitoring systems within waste management facilities.

Key Benefits of Installing Air Quality Monitoring Systems

Ongoing Pollution Monitoring

Monitoring systems provide real-time information on particulate matter, VOCs, H₂S, and other harmful air pollutants. This ensures the facility operators can monitor emissions on an ongoing basis and detect trends, maintaining air quality within safe and regulatory levels.

Better Operational Efficiency

By recognizing variations in air quality associated with specific processes, facilities can enhance their waste processing, handling, and incineration operations. Such an approach prevents avoidable emissions and improves overall process performance.

Regulatory Compliance

Environmental monitoring of air ensures regulatory compliance with local and federal environmental policies. Automated alerts ensure timely action, avoiding noncompliance and fines.

Improved Workplace Safety

Real-time monitoring allows for early detection of toxic gases such as hydrogen sulfide or ammonia, which shields employees from harm and creates a cleaner working environment.

Environmental Responsibility

With knowledge and effective emissions control, waste management facilities can minimize their impact on the environment. This not only aids in the sustainability campaign but also reflects corporate responsibility.

Data-Driven Decision Making

Collected data can shape long-term planning and infrastructure improvements, helping facilities in carrying out focused actions that resolve air quality challenges efficiently.

Best Practices for Air Quality Monitoring in Waste Management Facilities

To maintain optimal air quality, waste management facilities should adopt a mix of proven technical and operational practices. Strategic placement of sensors is necessary to ensure that monitoring points are located in high-emission areas, including landfills, shredding, and composting areas. Proper calibration and upkeep of sensors ensure data accuracy, while incorporating weather and operational data allows for more insight into pollutant patterns. Facility managers can make effective operational decisions using real-time dashboards and alerts, enabling them to respond to any variations in pollutant levels quickly. Further, cooperating with trusted air quality solution providers such as Oizom can boost monitoring capacity, offering advanced analytics, remote access, and automated reporting.

Conclusion

Air quality at waste management facilities is not just a compliance measure; it’s a measure of the operation’s accountability with its surroundings and community. Dust, odors, and gas emissions are inevitable issues, but with systematic monitoring and skilled management, facilities can limit their impact to a minimal level. By understanding the sources and behaviors of emissions, operators can make informed decisions that combine operational productivity with environmental responsibility. In the end, investing in air quality monitoring solutions and awareness isn’t so much a matter of complying with regulations; it’s about developing sustainable practices that serve employees, neighboring communities, and the overall ecosystem.

Frequently Asked Questions (FAQs)

Commonly monitored pollutants include particulate matter (PM2.5 and PM10), volatile organic compounds (VOCs), hydrogen sulfide (H₂S), ammonia (NH₃), and nitrogen oxides (NOx).

Yes. Real-time monitoring can detect harmful gases early, providing alerts that protect workers from exposure and reduce the risk of accidents.

While there is an initial investment, modern monitoring systems are cost-effective over time, helping reduce regulatory fines, operational inefficiencies, and environmental risks.