Summary of blog

Odour pollution is easy to ignore until it starts affecting daily life. Whether it’s from a landfill, factory, or wastewater plant, strong smells in the air can impact health, comfort, and even property value.

This blog explains what causes odours, how our nose detects them, and why they’re tricky to measure. We look at common odour-causing gases like hydrogen sulphide (rotten egg smell), ammonia, and VOCs, and how they combine to form complex smells.

Measuring odour isn’t just about identifying one gas; it’s about understanding how different gases interact, how often the odour occurs, and how strong or unpleasant it feels. We explore various methods used today, from human-based olfactometry to advanced tools like electronic noses (e-noses) and gas analyzers. We also highlight how smart systems like Oizom’s Odosense are helping monitor odour in real time using sensor networks and AI.

As cities grow and people demand cleaner environments, smarter odour monitoring is becoming essential. The future lies in combining data, technology, and quick action to create healthier and more liveable spaces. If you care about clean air and better monitoring, this blog is a great place to start.

Odour Measurement: Smart Monitoring for Better Air Quality

Ever walked past a waste site or food factory and wrinkled your nose at the strong, unpleasant smell? That’s odour pollution, an invisible but impactful part of air quality that’s often overlooked. Unlike dust or gases, odour doesn’t just affect your health; it directly impacts comfort, quality of life, and even property value.

With growing urbanization and industrial expansion, managing odour emissions has become more important than ever. Whether it’s from wastewater treatment plants, landfills, or food processing units, odour can signal underlying air quality issues and compliance gaps.

Thankfully, technology has stepped in. Today, smart odour monitoring systems use real-time sensors and IoT connectivity to detect and track odour levels with remarkable accuracy. These systems don’t just log data; they provide actionable insights that help industries stay compliant, minimize complaints, and build trust with local communities.

In this blog, we’ll break down how odour is measured, why it matters, and how smart monitoring can transform how we tackle this invisible pollutant. Let’s dive in.

Understanding Odour: What Makes a Smell?

We all recognize a bad smell instantly, but what exactly causes it? Technically speaking, odour is the human perception of volatile chemical compounds (VOCs) that evaporate easily into the air and stimulate our olfactory receptors. These compounds can come from natural sources like decaying organic matter or industrial activities such as chemical manufacturing, food processing, or waste treatment.

Odours aren’t just one-dimensional. A single unpleasant smell can be a mix of hundreds of different compounds, including hydrogen sulfide (the infamous “rotten egg” smell), ammonia, mercaptans, and various organic acids. The key factors that influence how we perceive these smells are concentration, frequency, intensity, duration, and hedonic tone (how pleasant or unpleasant a smell is).

From a monitoring standpoint, odour is tricky; it’s not a specific gas you can measure directly with a traditional sensor. That’s where smart odour monitoring comes in. Using a combination of gas sensors, electronic noses (e-noses), and machine learning algorithms, modern systems can detect specific odour patterns and correlate them with known sources.

This allows for real-time detection and source identification, making it easier for industries to take preventive or corrective actions. Odour units (OU/m³), a standard metric used globally, help quantify odour concentration meaningfully for regulatory compliance. In short, a smell is more than just a nuisance; it’s a chemical signal. And understanding it is the first step to controlling it effectively.

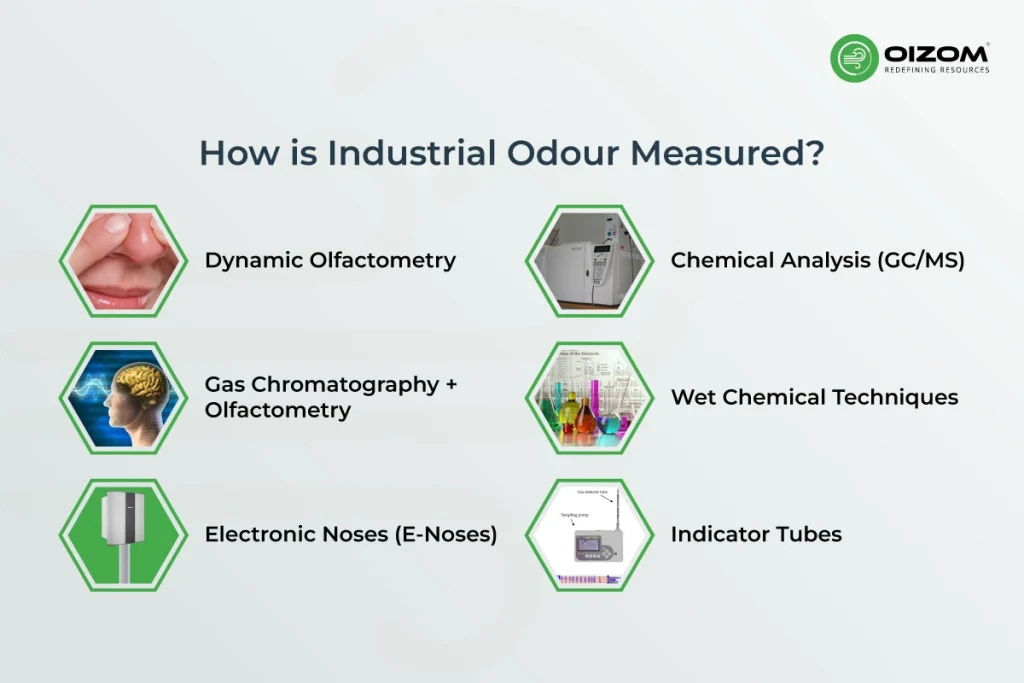

How is Industrial Odour Measured?

Industrial odour pollution stems mainly from volatile chemicals released into the air. These compounds can affect not just the surrounding environment, but also public health and community wellbeing. That’s why measuring and controlling odour emissions is critical, and thankfully, technology gives us several reliable ways to do it.

- Dynamic Olfactometry: This method relies on the human nose, but in a controlled and standardized way. An olfactory panel sniffs air samples to determine odour concentration, measured in European odour units per cubic metre (ouE/m³) under the EN 13725:2022 standard. It’s one of the most trusted approaches for its accuracy and repeatability.

- Gas Chromatography + Olfactometry: This hybrid method brings together high-tech instrumentation and human perception. While gas chromatography identifies the compounds, olfactometry connects them to how intense or unpleasant the odour feels to humans, bridging science and sensory experience.

- Electronic Noses (E-Noses): E-noses simulate the human sense of smell using sensor arrays and algorithms. They offer real-time, continuous monitoring, making them ideal for early detection and fast response in industrial setups. What makes them especially useful is their ability to monitor continuously and respond in real time, something traditional methods can’t always do. Devices like Oizom’s Odosense, which use this e-nose technology, are already out in the field tracking complex odour patterns in tough outdoor environments. It’s a smart way to turn something as subjective as smell into reliable, actionable data.

- Chemical Analysis (GC/MS): For a deeper dive into what’s in the air, gas chromatography-mass spectrometry pinpoints and quantifies specific odour-causing chemicals like H₂S or NH₃. Electrochemical sensors also support this,

- Wet Chemical Techniques: Used to detect compounds like mercaptans, these methods are valuable for analysing complex odour mixtures that traditional sensors might miss.

- Indicator Tubes: For quick field checks, these portable tubes change colour based on gas concentration. Simple, fast, and surprisingly effective.

While these tools measure the presence of compounds, the human experience of odour is more nuanced. Factors like odour complexity, detection thresholds, intensity, and exposure duration all play a role in how it’s perceived and how bothersome it becomes.

Key Parameters for Odour Measurement

When it comes to measuring odour, it’s not just about detecting a smell, it’s about understanding it in a structured, quantifiable way. Several technical parameters come into play, and each one helps define how an odour is perceived and managed.

- Odour Concentration: This is the most basic metric, expressed in odour units per cubic metre (ou/m³). It represents the dilution level at which an odour becomes detectable to the average human nose.

- Intensity: Intensity refers to how strong an odour is at a given concentration. Two samples might have the same odour concentration, but one could feel more overpowering than the other.

- Hedonic Tone: This parameter measures the pleasantness or unpleasantness of an odour. While subjective, it’s still an important factor, especially for community impact assessments.

- Frequency: How often does the odour occur? Even a mild smell can become a major issue if it’s persistent. Frequency helps capture that nuance.

- Duration: Duration tells us how long the odour stay in the environment. This is crucial for evaluating potential health impacts or nuisance levels.

- Thresholds: Two types matter, detection threshold (the lowest concentration detectable) and recognition threshold (the point at which the odour becomes identifiable).

Chemical Parameters (Odour-Causing Pollutants):

These are specific gases commonly associated with industrial odour emissions:

- Hydrogen Sulphide (H₂S): Smells like rotten eggs.

- Ammonia (NH₃): Pungent, sharp smell.

- Volatile Organic Compounds (VOCs): A broad group including alcohols, ketones, and aldehydes.

- Mercaptans: Extremely odorous, even at low concentrations.

- Sulphur Compounds & Amines: Common in waste and chemical industries.

If you’re looking to monitor odorous gases like H₂S, ammonia, VOCs, and methyl mercaptans, a solution like Oizom’s Odosense is designed precisely for that. Leveraging advanced e-nose technology, Odosense continuously detects, identifies, and tracks complex odour profiles in real-time, helping industries and municipalities take proactive action before odour becomes a public concern.

Want to see how it works in the real world? Take a look at our case study with ASA Bhanu Technical Services Ltd.. In this project, Odosense was deployed across a metro train depot in Ahmedabad, India, to monitor odour levels in the nearby area. The goal was to identify recurring odour events, pinpoint sources, and guide mitigation strategies to improve public comfort and environmental compliance.

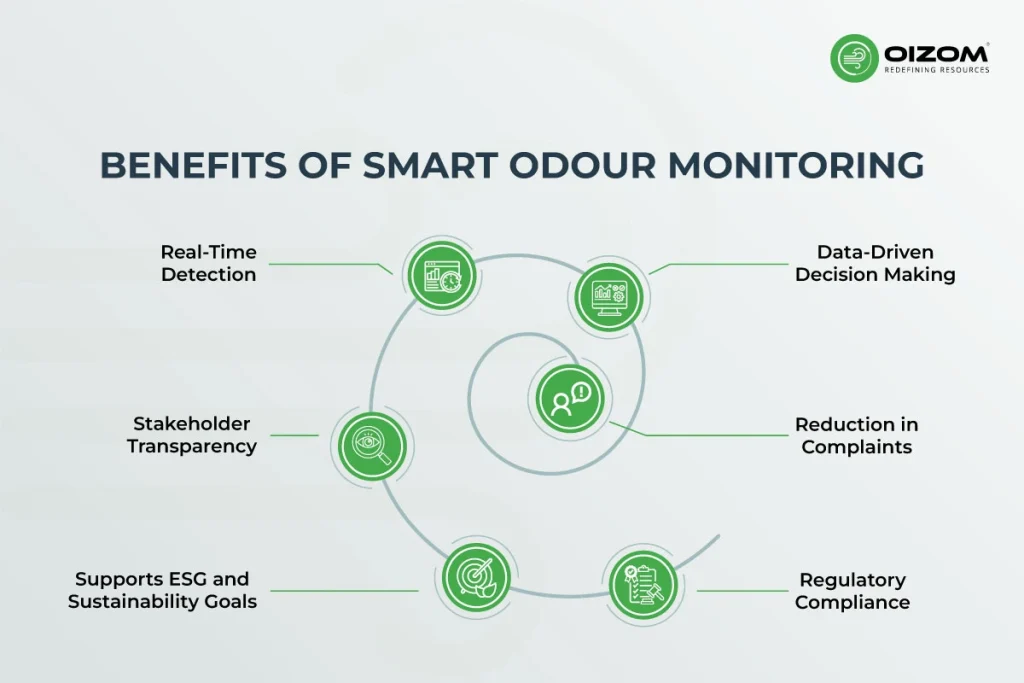

Benefits of Smart Odour Monitoring

Odour issues are no longer just about bad smells; they’re tied to public health, environmental compliance, and community relations. Smart odour monitoring solutions like Oizom’s Odosense offer a modern, data-driven way to address these challenges. Here’s how:

- Real-Time Detection: Smart monitors continuously track odorous gases, enabling immediate response before a minor issue turns into a public complaint or regulatory violation.

- Data-Driven Decision Making: By collecting and analyzing data over time, smart systems help industries identify patterns, such as recurring odour events during specific shifts or weather conditions, leading to more informed mitigation strategies.

- Reduction in Complaints: With early detection and quicker action, companies can proactively resolve odour sources, reducing the volume of complaints from nearby communities.

- Regulatory Compliance: Odour monitoring systems help maintain audit-ready records with accurate, time-stamped data. This supports compliance with local and international air quality regulations and reporting requirements.

- Stakeholder Transparency: Sharing real-time data dashboards with the public or government agencies builds trust and demonstrates environmental accountability.

- Supports ESG and Sustainability Goals: As ESG (Environmental, Social, Governance) reporting becomes standard, real-time odour monitoring contributes to measurable environmental performance and corporate responsibility.

Challenges in Odour Measurement

Measuring odour might sound simple, after all, if you can smell it, it’s there. But technically, odour measurement is far from straightforward. Odours are complex mixtures of volatile compounds, and their perception can vary widely from person to person, making standardization a real challenge.

One significant difficulty is the subjective nature of odour. While instruments can quantify gas concentrations, the human nose remains the primary detector in many methods, like dynamic olfactometry. This reliance on human panels introduces variability and requires controlled conditions for reliable results.

Another challenge is that odour is often a result of compound interactions rather than individual gases. For example, hydrogen sulphide (H₂S) or ammonia might be present in low concentrations, yet still contribute to a strong odour when mixed with VOCs or mercaptans. Measuring each component doesn’t always reveal the full odour profile.

Environmental factors, like wind, temperature, and humidity, also influence odour dispersion and perception, complicating real-time monitoring in outdoor environments. Sensors can struggle with fluctuating concentrations and background interference. Moreover, detection thresholds vary not only by compound but also by individual sensitivity, making it hard to set clear limits for regulatory compliance or public comfort.

Finally, while advanced tools like e-noses and Gas Chromatography-Mass Spectrometry (GC-MS) help bridge the gap between subjective experience and scientific measurement, they require calibration, contextual data, and often, expert interpretation. In short, odour measurement blends science and perception, and balancing both remains the core challenge.

Myth vs. Reality: Odour Monitoring

Odour pollution is often misunderstood, leading to myths that can downplay its impact or complicate management. Here’s a breakdown of common misconceptions and the facts that clarify them:

| Myth | Reality |

|---|---|

| If it doesn’t smell anymore, it’s gone. | Some odorous gases (like VOCs) can still stay or cause harm even when not detectable by the nose. |

| Odour monitoring is too subjective to be useful. | Modern tools like e-noses and GC-MS quantify odour with scientific precision, reducing reliance on human interpretation. |

| Odour isn’t regulated, so it's not a priority. | Many regions, including the EU and parts of India, are incorporating odour limits into air quality regulations. Non-compliance can lead to legal consequences. |

| One sensor is enough to monitor odour. | Odour is complex and multi-directional. Effective monitoring requires sensor networks to capture dispersion and identify sources accurately. |

| Community complaints are exaggerated. | Odour sensitivity varies, but persistent complaints often indicate a real and solvable air quality issue. Ignoring them can damage reputation and relations. |

Conclusion

Odour may be invisible, but its impact is anything but. Whether it’s the sharp scent of ammonia near a factory or the persistent stench from a landfill, odour pollution is a growing concern tied closely to air quality, public health, and environmental regulations.

As we’ve explored, monitoring odour isn’t just about “smelling the air”. It involves quantifying volatile compounds like H₂S, NH₃, and VOCs, understanding human perception, and analyzing data in real time. Technologies like electronic noses, GC-MS, and dynamic olfactometry are helping bridge the gap between subjective experience and scientific measurement. Tools like Oizom’s Odosense, built on e-nose technology, are already enabling industries to monitor, detect, and respond to odour events with precision.

Looking ahead, the future of odour monitoring lies in smarter integration, combining sensor networks with AI, meteorological modeling, and automated alerts to create predictive, responsive systems. This will not only help industries stay compliant but also empower communities with transparent data and faster mitigation.

In a world increasingly focused on sustainability and livability, managing odour is no longer optional; it’s a necessity. With the implementation of intelligent odour monitoring systems for improved air quality, we can make our environments cleaner, healthier, and far more breathable.

FAQs

Odour units per cubic metre (ou/m³) quantify the concentration of odour in air. It’s determined through methods like dynamic olfactometry, where a panel of trained human noses identifies the dilution level at which a smell becomes noticeable.

Yes. Having validated, time-stamped data from smart systems strengthens your position during audits, compliance checks, or public complaints. It proves proactive action and offers traceability.

E-noses offer high-frequency, real-time monitoring and are excellent for detecting recurring patterns. While GC-MS provides deeper chemical insights, e-noses are better suited for continuous field operations due to their speed and automation.

Industries like wastewater treatment, food processing, chemical manufacturing, landfills, and refineries benefit the most, as they often emit volatile compounds that cause odour-related discomfort and regulatory challenges.

Look for:

- Multi-gas detection (H₂S, NH₃, VOCs, etc.)

- Real-time alerts and cloud connectivity

- Historical data analysis and report generation

- Weather data integration (to track odour dispersion)

Easy installation and low maintenance