Ever stood at a busy seaport and felt the salt mix in the air and something not quite so fresh? That’s because seaports, while essential for global trade, are also hotspots for air pollution and unpredictable weather conditions. Beneath the hustle of cargo movement, diesel engines, and docking ships lies a complex web of environmental challenges.

From PM2.5 and NOx to SO₂ and VOCs, ports release a wide range of harmful pollutants. Add coastal winds, shifting humidity, and sudden temperature swings, and you’ve got a dynamic environment that’s tough to manage without the right tools. According to a report by the Centre for Energy, Environment, and Health, international maritime traffic causes over 50,000 premature deaths annually in Europe alone. That’s a wake-up call for anyone working in or around seaports.

That’s where real-time air quality and weather monitoring systems step in. Modern ports are turning to smart, sensor-based solutions to track emissions, measure meteorological data, and stay ahead of compliance requirements like MARPOL Annex VI. These systems not only protect workers and nearby communities but also help optimize operations and meet ESG targets.

In this blog, we’ll explain how advanced monitoring technologies, like IoT-connected air quality sensors and rugged weather monitoring devices, are transforming the way seaports manage their environmental footprint. If you’re working at the intersection of sustainability, compliance, and port operations, this guide is for you.

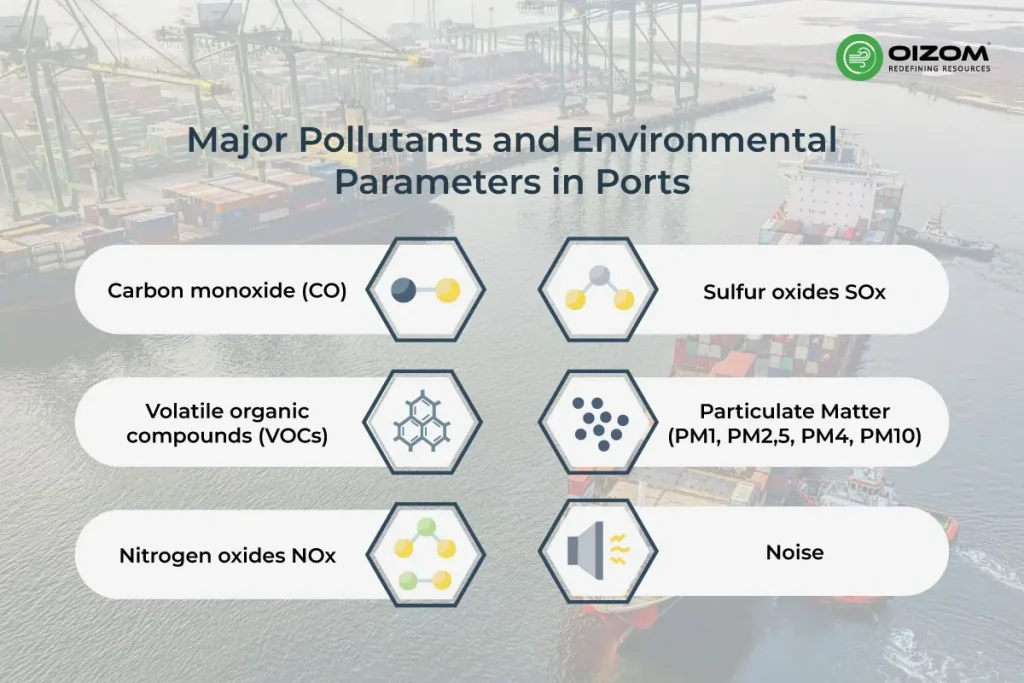

Major Pollutants and Environmental Parameters in Ports

Air quality at ports is becoming a serious concern. While ports play a key role in global trade and logistics, they also contribute significantly to pollution. The constant movement of ships, trucks, and cargo-handling equipment releases harmful emissions that impact the environment and people’s health. Here’s a quick look at the main types of pollution commonly found in port areas.

Ports release several harmful pollutants into the air. These include carbon monoxide (CO), volatile organic compounds (VOCs), nitrogen oxides (NOx), sulfur oxides (SOx), and tiny particles known as particulate matter (PM). In addition to air pollution, ports are significant sources of noise pollution from ships, trucks, and machinery.

Carbon monoxide (CO)

Carbon monoxide is a colorless, odorless gas mainly released from the incomplete combustion of fossil fuels. At ports, it’s commonly emitted by ships, cargo-handling equipment, and diesel-powered trucks. Prolonged exposure to CO can limit oxygen in the bloodstream, leading to symptoms like fatigue, headaches, and dizziness. For port workers and nearby communities, high CO levels can pose serious health risks, especially in busy, high-traffic zones.

Volatile organic compounds (VOCs)

VOCs are a group of light hydrocarbon gases, like methane, ethane, propane, and butane, that easily evaporate at normal temperatures. At ports, they are mostly released during the loading and transport of crude oil or fuel. When cargo is transferred into tanks, some of it turns into vapor and escapes into the air, especially through the piping system and tank vents.

During loading, gases already present in the tank, like nitrogen, carbon dioxide, and leftover VOCs, mix with new hydrocarbon vapors from the cargo. As the tank fills, pressure builds up and forces these vapors out into the atmosphere.

Reducing VOC emissions is important not only for protecting the environment but also for minimizing the loss of valuable fuel components.

Nitrogen oxides NOx

Nitrogen oxides are harmful gases released mainly from the engines of ships, trucks, and other vehicles. At ports, NOx emissions are a major concern because they can cause breathing problems and harm the environment. These gases contribute to smog, acid rain, and even global warming. They can also damage soil, water, and plant life.

Controlling NOx emissions is essential to protect human health and preserve ecosystems around port areas and beyond. Were you aware of this? Annual NOx ship emissions can reach 5–10 % of total global emissions and even 30–40 % at the regional level (Ramacher et al., 2020)

Sulfur oxides SOx

Sulfur oxides are harmful gases released when ships burn fossil fuels with high sulfur content. These emissions can cause breathing problems, contribute to acid rain, and harm the environment. Acid rain damages forests, water bodies, and buildings and can seriously affect aquatic life.

SOx can also reduce visibility, making maritime and land transport less safe. Managing these emissions is key to protecting health, ecosystems, and transportation safety around port areas.

Particulate Matter (PM1, PM2,5, PM4, PM10)

Particulate matter (PM) refers to tiny particles like soot and ash that are small enough to be inhaled deep into the lungs and even enter the bloodstream. These particles are produced by fuel combustion and material handling during port operations.

Exposure to PM can lead to serious health issues, including heart and lung diseases. It also affects plants, animals, and local ecosystems by disturbing the natural balance. Managing PM levels at ports is essential to protect human health and environmental well-being.

Some works have focused on the identification and estimation of the impact of harbor activities on ambient PM levels in nearby urban areas since loading, unloading, and transport operations of dusty loose materials may have a significant impact on PM levels with subsequent potential effects on human health.

In Europe, shipping is a significant source of air pollution; PM2.5 and PM10 comprise 45% and 28% of shipping-related emissions, respectively (Merico et al., 2021). Ultrafine particles from cruise ships and ferries can affect the health of dockworkers and people living near ports like Barcelona, Venice, and Southampton. Globally, PM2.5 pollution from boats is linked to 14,500–37,500 premature deaths, especially in densely populated coastal areas.

Noise Pollution

There are several reasons why noise pollution in port locations is a problem for the environment and public health. Noise levels from loading and unloading activities, as well as port activity in general, are high. This is on top of the continuous flow of automobiles and large machinery and the presence of people and maritime activity. In addition to stressing out marine life and changing its natural habitats, this combination of noise has a negative impact on human health by causing psychological stress and hearing issues. Therefore, controlling noise pollution is essential to the long-term viability of maritime operations and the standard of living in the surrounding communities.

Technologies Used in Seaport Monitoring

Modern seaports are evolving into data-driven ecosystems. To manage air quality and weather conditions effectively, they rely on a combination of advanced monitoring technologies that deliver real-time, accurate insights. These tools are essential for regulatory compliance, operational efficiency, and environmental safety.

Sensor-Based Air Quality Monitors

Air quality monitors use a range of sensor technologies at ports to detect pollutants like CO, NOx, SO₂, VOCs, and particulate matter (PM1, PM2.5, PM10). Electrochemical sensors are widely used for detecting gases at low concentrations, offering high sensitivity and fast response times. NDIR (Non-Dispersive Infrared) sensors are ideal for measuring gases like CO₂, using infrared light absorption to deliver stable and reliable readings. These sensors are housed in rugged, weatherproof enclosures suitable for extreme marine environments, ensuring consistent performance.

Sensor Comparison Table for Port Monitoring

| Parameter | Electrochemical Sensors | NDIR Sensors | Optical PM Sensors |

|---|---|---|---|

| Detection Limits | ppb to the low ppm range | ppm (gas-specific) | 0.1 µg/m³ (depending on size) |

| Cross-sensitivity | High (needs compensation) | Low | Can miscount humidity as PM |

| Maintenance | 6–12 months recalibration | 12–24 months | Monthly cleaning (especially near sea) |

| Environmental Drift | Prone to temperature/humidity | Moderate | High in coastal corrosion zones |

Weather Monitoring Devices

Weather plays a critical role in pollutant dispersion and maritime safety. Ultrasonic anemometers measure wind speed and direction without moving parts, making them highly durable and accurate even in coastal conditions. Solid-state semiconductor sensing monitors temperature and humidity, two key parameters influencing pollutant behavior and worker safety. Additional sensors for barometric pressure and rainfall are also commonly integrated to provide a comprehensive environmental profile.

Did you know this? One such solution that fits right into this setup is Weathercom. Designed for harsh outdoor conditions, it offers reliable, high-resolution weather data without the complexity.

What’s more, it’s trusted by leading meteorological organizations, including the India Meteorological Department (IMD) and the World Meteorological Organisation (WMO), a quiet nod to its accuracy and dependability. Because when it comes to port operations, you’re not just managing logistics, you’re working with the wind, watching the sky, and staying one step ahead of nature.

IoT and Real-Time Data Transmission Technologies

IoT-enabled systems collect and transmit data from multiple sensors to cloud platforms in real-time. Using protocols like MQTT, LoRaWAN, or 4G/5G, these systems support remote monitoring, alerts, and analytics. Integration with dashboards or SCADA systems allows port authorities to make informed decisions instantly, enhancing safety, compliance, and operational planning.

Polludrone, for instance, is engineered for seamless SCADA integration via standard protocols like RS-485 (Modbus RTU), enabling direct interfacing with industrial automation infrastructure. This ensures that environmental data can be visualized and acted upon in the same environment as other critical operational parameters.

By consolidating air quality insights into established control systems, port authorities can enhance regulatory compliance, worker safety, and operational planning, all from a unified interface.

Ensuring Data Quality in Coastal Monitoring

For any high-stakes application, environmental data is only as good as its accuracy, completeness, and consistency. In coastal port environments, where high humidity, salt spray, and fluctuating meteorological conditions are the norm, maintaining robust QA/QC is critical to prevent misinterpretation and ensure regulatory compliance.

Key QA/QC Practices for Port Monitoring:

- Baseline Drift Correction: Regular calibration ensures the long-term accuracy of gas and particulate sensors. This can be achieved through automated zero/span checks or periodic co-location with certified reference stations for recalibration.

- Cross-Sensitivity Compensation: Advanced correction algorithms are used to mitigate the effects of gas interference (e.g., O₃ falsely elevating NO₂ readings). Sensor networks often apply multi-parameter models to isolate true concentrations from cross-reactive influences.

- Anomaly Detection: Outlier readings due to environmental disruptions or sensor faults are filtered using statistical techniques like Z-score and IQR. For advanced setups, machine learning models trained on historical trends provide real-time anomaly detection with higher precision.

- Data Imputation: Sensor outages due to power failure, corrosion, or network loss are common in port zones. Smart imputation techniques, ranging from time-series models to AI-powered regression, fill data gaps, ensuring continuity for compliance and analytics.

By incorporating these quality control protocols into your sensor network and platform, ports can enhance data integrity, reduce false alarms, and support credible environmental reporting.

Why do Oizom Air Quality Monitoring Devices truly stand out in the air quality monitoring space?

Because we don’t just build monitors; we build trust in data. Every Oizom air quality monitoring device is first calibrated in an ISO/IEC 17025:2017 certified lab using NIST-traceable gas standards, strictly following international guidelines (U.S. EPA Vol II, Section 6.0 Rev.1).

But we don’t stop there.

After lab calibration, each device goes through a second level of testing, collocation with a custom-built reference station equipped with U.S. EPA-designated Federal Equivalent Method (FEM) analyzers as per the US EPA Air Sensor Collocation Instruction Guide. This double-layered approach ensures that Oizom delivers data you can depend on every single time.

Integration with Port Operations and Compliance Systems

Air quality monitoring in ports goes beyond just measuring pollutants; it’s about making that data usable within existing port operations. Seamless integration with operational systems allows port authorities to enhance planning, reduce risks, and comply with evolving environmental standards.

Linking Air Quality Data with Ship Arrival/Departure Schedules

Ports are dynamic environments, with emissions often peaking during ship arrivals and departures. By synchronizing air quality data with vessel schedules, port operators can better identify high-emission periods and implement control strategies, like shifting operations or increasing ventilation during peak times. This linkage also helps identify emission patterns based on ship type, fuel used, and docking time, enabling more accurate source attribution and emission forecasting.

Integration with DCS/SCADA Systems

For real-time control and automation, integrating air quality monitors with DCS (Distributed Control Systems) or SCADA (Supervisory Control and Data Acquisition) platforms is essential. This ensures that air quality data can be processed, visualized, and acted upon alongside other operational metrics like fuel usage, engine status, or gate control, allowing faster, more informed decision-making.

Meeting MARPOL Annex VI and Local Environmental Regulations

Environmental regulations like MARPOL Annex VI place strict limits on emissions from ships. Integrated monitoring systems ensure ports have continuous, auditable data to demonstrate compliance. Local air quality norms can also vary by region; hence, having a real-time, regulatory-aligned system in place supports both enforcement and transparent environmental reporting.

Understanding MARPOL Annex VI

MARPOL Annex VI is an international regulation under the International Maritime Organization (IMO) aimed at controlling air pollution from ships. It sets strict limits on emissions of sulfur oxides (SOx), nitrogen oxides (NOx), particulate matter (PM), and ozone-depleting substances from ship exhausts and shipboard incineration processes.

One of its most impactful requirements is the global sulfur cap, which, as of January 1, 2020, limits the sulfur content in marine fuels to 0.50% m/m (mass by mass), down from the previous limit of 3.50%. In Emission Control Areas (ECAs), this limit is even stricter at 0.10% m/m. These controls are designed to reduce respiratory and cardiovascular problems in humans and minimize environmental harm, such as acid rain.

Annex VI also includes Tier I, II, and III NOx emission standards, which apply based on the ship’s engine power and date of construction. Tier III standards, for example, are mandatory in NOx Emission Control Areas (NECAs) and target new ships operating in these zones.

For ports, having integrated air quality monitoring systems that track SOx, NOx, and PM in real time plays a crucial role in verifying compliance with MARPOL Annex VI. These systems enable data logging, reporting, and integration with ship tracking and inspection frameworks, making it easier for port authorities and shipping operators to demonstrate adherence to IMO regulations.

By aligning port monitoring infrastructure with MARPOL standards, stakeholders can ensure smoother inspections, avoid penalties, and contribute to cleaner, safer maritime operations.

Benefits of Real-Time Seaport Monitoring

Real-time air quality and weather monitoring is becoming an essential part of port management. It not only supports compliance but also improves safety, operational efficiency, and public trust. Here’s how:

Regulatory Compliance

With increasingly strict global and regional regulations like MARPOL Annex VI, ports must continuously monitor pollutants such as SOx, NOx, PM, and VOCs. Real-time monitoring systems ensure that emissions data is recorded, timestamped, and readily available for audits and environmental reporting. Integration with ship activity logs also helps validate emission sources during inspections or compliance checks.

Enhanced Safety for Workers and Nearby Populations

Ports are high-traffic zones where workers, equipment, and the environment intersect. Exposure to harmful gases or fine particles can pose serious health risks. Real-time alerts for elevated pollution levels or adverse weather conditions help mitigate exposure and allow safety protocols to be triggered instantly, reducing risks for both workers and surrounding communities.

Predictive Maintenance and Operational Optimization

By correlating environmental data with machinery operation, ports can detect early signs of equipment inefficiencies or excessive emissions. For instance, unexpected PM spikes could indicate filter failure in cargo-handling equipment. These insights enable predictive maintenance, reduce downtime, and support data-driven decision-making for optimized scheduling and fuel use.

Community and Stakeholder Transparency

Transparent environmental reporting builds public trust and strengthens stakeholder relationships. Real-time data dashboards and open-access platforms allow communities, regulators, and port users to view environmental performance, helping ports demonstrate accountability and support broader ESG (Environmental, Social, Governance) goals.

Dashboards like Envizom allow ports to display live data on key weather parameters, such as wind speed, direction, temperature, humidity, and barometric pressure, alongside air quality metrics. These platforms make it easy for regulators, port users, and nearby communities to access environmental performance at a glance, driving more informed engagement and supporting ESG (Environmental, Social, Governance) goals.

A recent example is Portlinks India, which implemented Weathercom integrated with Envizom to streamline its operations and enhance transparency. The system provides a centralized, real-time view of on-site environmental conditions, helping both internal teams and external stakeholders monitor changes and make timely decisions.

Conclusion

As global trade grows, so does the environmental responsibility of ports. From real-time air quality and weather sensors to IoT-driven dashboards like Envizom, modern monitoring technologies are helping ports stay compliant, protect health, and optimize operations, all in one smart ecosystem.

We’ve seen how integrated systems can link environmental data with ship schedules, SCADA controls, and even community dashboards. The benefits? Better decision-making, safer workplaces, regulatory compliance, and increased transparency.

Looking ahead, ports are beginning to adopt AI-based forecasting models, combining satellite imagery with ground-level sensor data to predict pollution events before they happen. These innovations will further enhance proactive environmental management and help ports operate more sustainably in complex coastal environments.

In short, real-time environmental monitoring isn’t just a technical upgrade. It’s a strategic move toward smarter, greener seaport operations. Now’s the time to rethink how your port measures the air and weather. Ready to make your port future-ready? Let’s start with the right monitoring solution.