Summary

Behind the green promise of fertilizers, there is an escalating air pollution crisis. From factory smoke to farm fumes, the fertilizer sector is emitting pollutants that harm people’s health, the climate, and compliance. Fertilizers are needed for world food security, yet their wasteful use, with up to 70% of nitrogen being emitted into the atmosphere, results in the emission of ammonia, nitrogen oxides, and potent greenhouse gases such as nitrous oxide.

Populations around fertilizer clusters like Gujarat’s Bharuch are already being affected. But the majority of these emissions pass undetected and unchecked because there is no real-time air quality data to monitor them.

This blog delves into where and how air pollution from fertilizer is created, what pollutants are present, and the regulations surrounding it. More so, it focuses on how live air quality monitoring (AQM) systems can assist the industry in sensing, minimizing, and reporting emissions both at the plant and field level.

The future of green fertilizers is not only in the ground but in the air we breathe.

Air Pollution from the Fertilizer Industry

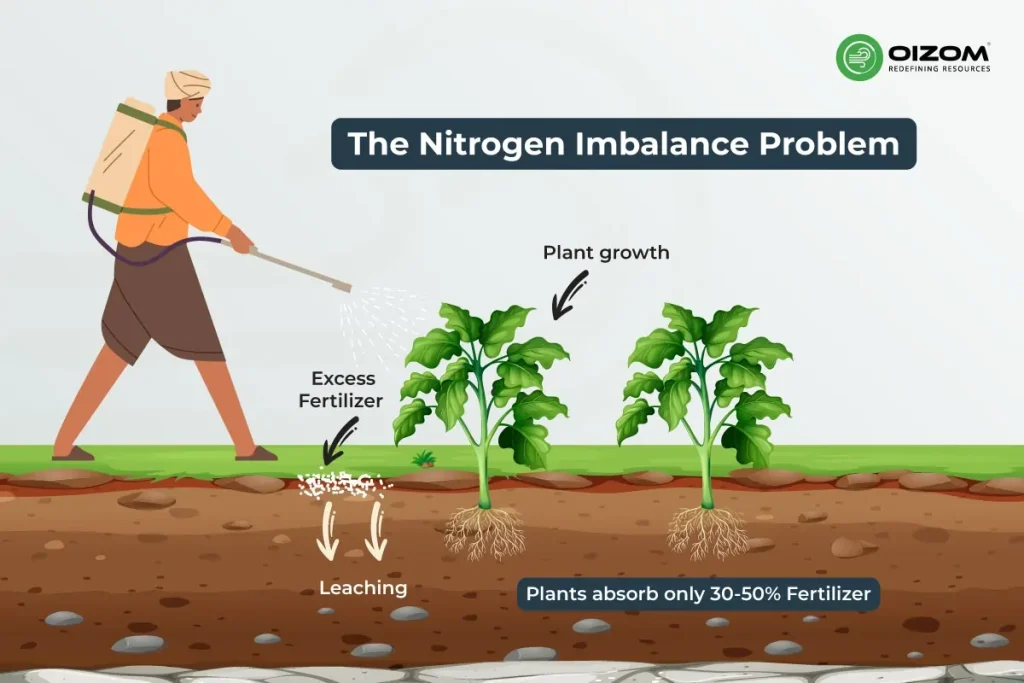

Fertilizers push food production around the world, but their wasteful application has a sneaky price tag. Typically, only 30–50% of nitrogen applied to crops is actually taken up; the remaining escapes into the air as pollutants such as ammonia (NH₃), nitrogen oxides (NOₓ), and nitrous oxide (N₂O). These emissions upset the nitrogen cycle, degrade air quality and drive climate change.

The effect can be seen in areas such as Bharuch, Gujarat, where the people living around fertilizer plants have increasing respiratory problems. Pollution does not start at the factory when fertilizers are used; rural air experiences a surge in toxic gases, usually without a warning or visibility.

At this time, when air pollution from the fertilizer industry is spreading across both industrial zones and farmlands, environmental regulations are tightening. However, without real-time monitoring over fertilizer plants and fields, critical emissions remain untracked.

In order to construct an age where farming and clean air are in sync, the sector needs to adapt to smart tools. Real-time AQM systems provide a practical option for assisting in detecting, controlling, and curbing emissions from source to soil.

The Nitrogen Imbalance Problem

Fertilizers are integral to agriculture, but their misuse and waste have brought about a significant distortion of the natural nitrogen cycle. On average, crops take up only 30–50% of the added nitrogen; the remaining escapes into the environment as airborne pollutants. This imbalance results in the release of ammonia (NH₃), nitrous oxide (N₂O), and nitrogen oxides (NOₓ) into the air.

Ammonia (NH₃) combines with other pollutants to produce fine particulate matter (PM2.5), a significant health risk.

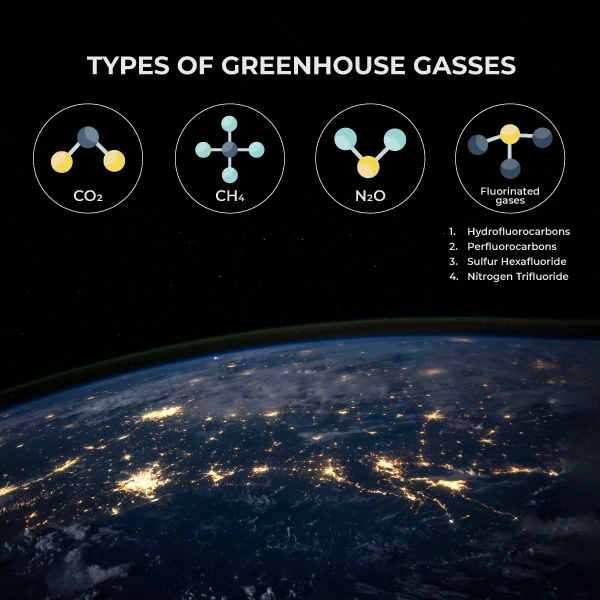

Nitrous oxide (N₂O) is a powerful greenhouse gas, 300 times more powerful than CO₂ over 100 years.

Nitrogen oxides (NOₓ) are involved in the formation of smog, acid rain, and respiratory ailments.

But the nitrogen problem does not end there. The manufacture and application of fertilizers can also create emissions of volatile organic compounds (VOCs), particulate matter, and even sulphur compounds, depending on raw materials and the process employed.

These air pollutants not only lower the local, regional air quality but also make it difficult to meet environmental standards, particularly in areas sensitive to residential or ecologically valuable land.

This is where real-time air quality monitoring (AQM) is critical. Monitoring systems can identify pollutant levels at key stages of emissions, including storage, blending, transport, and field application, enabling stakeholders to make informed choices, apply specific controls, and show regulatory compliance.

Where Fertilizer Pollution Begins

From the manufacturing to the agricultural field, air pollution from fertilizer comes in two broad phases. The first starts with the manufacturing process itself. In large production units, the synthesis of ammonia (through the Haber-Bosch process), nitric acid, and other nitrogenous compounds includes high-temperature chemical reactions that emit pollutants such as ammonia (NH₃), nitrogen oxides (NOₓ), sulphur oxides (SOₓ), particulate matter (PM), and volatile organic compounds (VOCs). Even blending and granulation may result in considerable dust emissions.

Unless monitored correctly in real time, these stack and fugitive emissions usually pass undetected, causing regulatory violations and community-scale air quality effects.

The second source of pollution occurs far from industrial areas on agricultural land. Upon application of fertilizers, particularly in excessive or poor soil quality, gases such as NH₃, N₂O, and NOₓ are emitted through complex microbial processes in the soil. These emissions are not always visible, yet they quietly impair air quality, enhance rural haze, and even intensify smog spells in nearby areas. Monitoring air quality, particularly with remote or mobile systems, can identify such Widespread emissions and help promote more environmentally friendly fertilizer use.

What Do The Fertilizers Release In Air?

Fertilizers might appear harmless on the surface, but beneath them lies a trail of airborne emissions. Whether through manufacturing in industrial estates or after application in open fields, fertilizers emit a mix of gases and particles that impact air quality across rural-urban divides. The following are the key pollutants of concern:

Ammonia (NH₃): Emitted both in production and when used on the field, ammonia is a sharp-smelling gas that helps form secondary particulate matter (PM2.5) when it interacts with other atmospheric molecules such as Sulphur and nitrogen oxides. High levels of NH₃ are commonly found near fertilizer factories and highly cultivated regions.

Nitrogen Oxides (NOₓ): Produced during combustion-intensive manufacturing operations (e.g., production of nitric acid), NOₓ also indirectly arises from soils after the use of fertilizer. These reactive gases contribute to the decline of local air quality and are also a primary contributor to ground-level ozone formation.

Particulate Matter (PM): Granulation, blending, packaging, or transportation spillage dust can result in major PM10 and PM2.5 emissions. In rural areas, secondary PM2.5 from NH₃ is one of the major haze contributors.

Nitrous Oxide (N₂O): A greenhouse gas is around 300 times stronger than CO₂, N₂O is released from fertilised soils predominantly through microbial processes. Though it is less spoken of in the air quality sector, it acts as both a climate pollutant and a stratospheric ozone depleter.

Sulphur Oxides (SOₓ): During the production of sulphur-based fertilizers, e.g., ammonium sulphate or single superphosphate, SO₂ can be released during acidulation.

Volatile Organic Compounds (VOCs): Employed in coating or processing certain specialty fertilizers, VOCs can be emitted during handling or storage and contribute to smog formation.

Monitoring these emissions in real time by using air quality monitoring systems is the essence of both environmental compliance and sustainable agriculture.

Impacts, Regulations and Global Realities

Air pollution resulting from fertilizer production is not just an industrial issue, but also a public and environmental problem as well. Emissions of ammonia, NOₓ, PM, and VOCs during production can lead to smog formation, breathing difficulties, and even long-term health threats like cardiovascular disease. A harsh example is: the Bharuch district in Gujarat which saw a much higher rate of respiratory disorders among the local populations living closer to a high concentration of fertilizer and chemical units.

Along with air, fertilizers influence soil and water via nitrogen deposition and acidification, disrupting regional ecosystems and shifting nutrient budgets. From the regulatory perspective, nations are tightening their control over emissions. For instance, the European Union has strict regulations on ammonia and NOₓ emissions through the NEC Directive, while the US EPA controls NOₓ and PM from nitric acid facilities.

In India, fertilizer units come under CPCB’s Emission Norms, particularly for urea facilities, but enforcement as well as monitoring vary from state to state. As international attention turns to sustainable farming and cleaner industrial processes, synchronizing fertilizer production with clean air policy is no longer a choice, but a necessity.

Different Types of Fertilizers: Not All Pollution Comes from the Same Source

The fertilizer industry is not about a single process or product but a multifaceted blend of chemical, organic, and hybrid solutions. Each has its own manufacturing processes, emissions profile, and environmental trade-offs. Knowing the different types of fertilizers helps pinpoint where air quality monitoring (AQM) is needed most.

1. Inorganic (Synthetic) Fertilizers

These are ammonium nitrate, urea, and superphosphates, which are manufactured in energy-intensive chemical processes from natural gas, sulphur, and extracted minerals. They emit NOₓ, NH₃, SO₂, and PM upon manufacture, hence calling for stack monitoring and control of emissions. High requirement for AQM at factories of manufacture and in bulk transport/storage.

2. Organic Fertilizers

Organic fertilizers, which are produced from plant residues, compost, manure, or animal by-products, are generally perceived as being environmentally friendly. Still, their use can give off methane, VOCs, and ammonia, particularly in extensive use or in inadequate storage. Farm and composting site monitoring is critical, particularly for NH₃ and odour-emitting VOCs.

3. Biofertilizers

This uses living microorganisms to maximize the availability of nutrients in soil. They are low-emission but can also release trace gases during fermentation or decomposition. AQM could be minimal at the production level but valuable in confirming field-level air quality gains.

4. Slow-Release & Controlled-Release Fertilizers

Designed to minimize leaching and volatilisation, they curtail emissions during the application stage. However, they tend to have a synthetic structure, and hence, upstream emissions can be present. Best candidates for examining before-and-after real-time AQM data comparisons to evaluate actual gains.

5. Blended or Hybrid Fertilizers

Synthetic nutrients blended with organic material or stabilisers are common in many products. Subsequent emissions can be multifaceted and changing, based on composition. They are prospective candidates for bespoke AQM arrangements to track emissions along the value chain.

Cleaner Methodologies

Key Areas of Intervention to Reduce fertilizer-Associated Emissions:

Low-Carbon & Bio-Based Feedstocks (Cleaner Inputs)

Green ammonia, which is manufactured from renewable energy rather than fossil fuels, reduces NOₓ and CO₂ emissions significantly from its source. Equally, bio-based fertilizers produced from organic waste are a sustainable option compared to synthetic chemicals.

Enhancing Combustion & Chemical Reactions (Process Controls)

Upgrading low-NOₓ burners, closed-loop controls, and improved reactor designs for ammonia and urea plants can reduce emissions during production. Real-time monitoring of air quality identifies emission hotspots that are corrected immediately.

Emission Capture & Treatment

More sophisticated systems such as scrubbers, selective catalytic reduction (SCR), and dust collectors are necessary to capture NOₓ, PM, and ammonia emissions. These function optimally when complemented with continuous emission monitoring systems (CEMS) for maximum performance and compliance with regulations.

Smart fertilizer Application: Precision Farming

Not all NH₃ and N₂O emissions are from factories; a significant portion of NH₃ and N₂O emissions are emitted after fertilizers have been used in the field. Options like nitrification inhibitors, slow-release products, and AI-based precision dosing can substantially reduce these emissions. Measuring nearby air quality in rural areas assists in ascertaining real-world impact and informing more intelligent policy.

Integrated Air Quality Monitoring (AQM)

At each level, from stack emissions at factories to escaping gases from warehouses and field-level diffusion, the use of strong AQM solutions is crucial. Solutions such as Oizom’s enable real-time monitoring of pollutants such as NH₃, NOₓ, PM, and VOCs continuously, enabling actionable insights for compliance, efficiency, and early response.

Role of Real-Time Air Quality Monitoring

The fertilizer industry releases a variety of pollutants during production, application, and other related activities, including ammonia (NH₃), hydrogen sulfide (H₂S), volatile organic compounds (VOCs), particulate matter (PM2.5, PM10), and nitrogen oxides (NOₓ). These emissions can lead to multiple health and environmental risks if not adequately monitored and controlled.

This is where real-time air quality monitoring comes into play. By providing continuous, real-time, and accurate data, it aids in detecting pollutant spikes, identifying leakages, and taking timely action to maintain regulatory compliance and address safety hazards.

Oizom’s advanced sensor-based ambient monitoring systems, such as Polludrone and Odosense, are designed for industrial environments like fertilizer plants. It offers:

1.Accurate measurement of NH₃, H₂S, VOCs, PM, and NOₓ and other critical pollutants.

2.Live alerts for emissions beyond limits.

By integrating Oizom’s monitoring instruments, fertilizer manufacturers can ensure regulatory compliance, worker safety, minimize environmental impact, and improve process transparency.

Conclusion

The fertilizer sector is at a turning point. While some progressive operators are already embracing real-time air monitoring to ensure compliance and sustainability objectives, many others are depending on outdated methods that ignore hidden emissions. But in an age of clean air, climate response, and sustainable agriculture, this disconnect cannot be disregarded anymore.

Seamless integration of cutting-edge AQM technologies such as those provided by Oizom isn’t merely about compliance with emission standards. It’s about finding clarity in the unseen, making wise choices, and guiding the industry toward a world where productivity doesn’t compromise the planet.

Cleaner production of fertilizer and more intelligent application are not only feasible, they’re necessary. The future of farming is up to what we make of today’s air.