Summary

Glass is a fundamental material of modern life, producing basic items such as bottles, windows, and laboratory equipment. However, its production significantly impacts air quality by releasing suspended particulate matter (SPM), sulfur dioxide (SO₂), nitrogen oxides (NOx), carbon dioxide (CO₂), volatile organic compounds (VOCs), and trace heavy metals. These pollutants affect both humans and the environment, resulting in respiratory issues, smog formation, acid rain, and greenhouse gas accumulation.

Air quality monitoring is vital to this industry for protecting worker health, ensuring regulatory compliance, and minimizing environmental impact. Efficient monitoring approaches include real-time AQM systems, strategic sensor positioning, regular data collection, and integration with environmental management systems. Practices such as site surveys, equipment selection, sampling schedules, data analysis, worker training, and instrument maintenance improve monitoring and operational efficiency.

By tracking emissions, understanding air quality, and taking proactive steps, glass manufacturers can safeguard health, optimize operations, and contribute to a cleaner, safer atmosphere.

Why Air Monitoring Matters in Glass Manufacturing?

Glass manufacturing has long since been producing materials that sustain modern life, from bottles and windows to lab equipment. However, the process has a significant impact on the air we breathe. Glass manufacturing involves high-temperature operations, often exceeding 1500 °C. It usually releases a mixture of airborne pollutants, including suspended particulate matter (SPM), sulfur dioxide (SO₂), nitrogen oxides (NOx), and carbon dioxide (CO₂). Studies have shown that workers in glass plants are exposed to SPM levels up to 9x higher than ambient air, emphasizing the health risks from inhalation of fine dust, respiratory irritants, and other emissions.

Outside the plant, nearby communities can experience increased smog and acid rain due to these pollutants. Optimizing industrial efficiency with environmental duty and worker safety requires robust air quality monitoring and effective mitigation measures. Understanding the sources and scale of emissions is the first step in ensuring a safer, cleaner workplace and protecting the broader environment.

How Glass Manufacturing Impacts the Air We Breathe?

Glass production, though essential for modern life, drastically affects air quality. The process involves melting raw materials (such as silica, soda ash, and limestone) at high temperatures exceeding 1500 °C. These operations release various airborne pollutants that affect human health.

Suspended Particulate Matter (SPM) is one of the most visible emissions, coming from raw material handling and furnace use. Fine dust particles persist in the air for extended periods, settling into the lungs and increasing the risk of respiratory illnesses. Sulphur dioxide (SO₂) and nitrogen oxides (NOx) come from high-temperature combustion and refining. SO₂ results in acid rain and respiratory issues, while NOx leads to smog formation and aggravates asthma and bronchitis. Carbon dioxide (CO₂) is mainly emitted during fuel combustion and carbonate decomposition, driving the industry’s greenhouse gas footprint. In colored or other special glass, even trace emissions of heavy metals and VOCs can worsen the surrounding air quality.

The impact, however, is not just local. Regions with higher glass production, such as Uttar Pradesh in India or parts of Europe, show a significant rise in ambient pollutants, affecting nearby communities. Within plants, workers experience increased exposure due to high levels of pollutants and poor ventilation. Widely, glass manufacturing adds to localized as well as broader air pollution, highlighting its importance in the quality of the air we breathe.

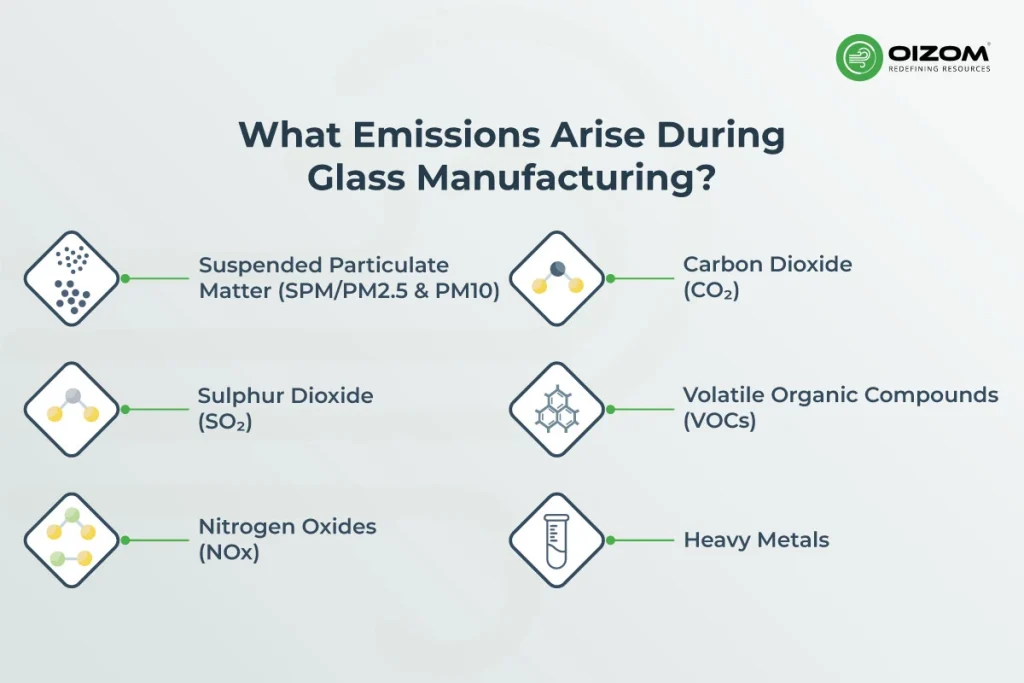

What Emissions Arise During Glass Manufacturing?

Glass production requires high temperatures and energy, and each production stage releases specific types of pollutants into the air. Understanding these emissions is vital for measuring both occupational and environmental impacts.

Suspended Particulate Matter (SPM/PM2.5 & PM10)

Dust comes from handling raw materials such as silica, limestone, soda ash, and also from molten glass operations. Fugitive dust also escapes from batch houses, conveyors, and storage areas.

Health impact: Inhaling fine particles leads to respiratory irritation, chronic bronchitis, and other lung-related issues.

Sulphur Dioxide (SO₂)

It’s produced when materials containing sulphate are heated in furnaces. Environmental impact includes acid rain and smog, and health impact includes eye, nose, and respiratory irritation.

Nitrogen Oxides (NOx)

NOx is primarily released during fuel combustion at high temperatures. It results in ground-level ozone formation and smog, as well as health risks such as aggravation of asthma and bronchitis.

Carbon Dioxide (CO₂)

Released from fuel combustion and carbonate breakdown in raw materials. Though not directly harmful, CO₂ significantly adds to global greenhouse gas emissions and reveals indoor ventilation efficiency.

Volatile Organic Compounds (VOCs) & Heavy Metals

They are common in colored or special glasses that require metal oxides. It can lead to toxic exposure and worsen air quality in nearby areas. The combination of all these pollutants refers to the impact on air quality both inside plants and the surrounding communities. Their overall effect is essential in maintaining long-term health and environmental safety.

Why is Air Quality Monitoring a Priority in This Industry?

Air quality monitoring is essential in glass manufacturing due to the industry’s nature of high emissions. Continuous tracking helps identify key pollution spots, determine worker exposure, and ensure compliance with standards.

Protecting Worker Health

Workers are vulnerable to SPM, SO₂, NOx, CO₂, and other trace pollutants through the production process. By monitoring pollutant levels, plant managers can take proactive steps to reduce exposure, improve ventilation, and safeguard employee health.

Preventing Environmental Impact

Point emissions from furnaces, batch houses, and machines extend beyond the workplace and further harm ambient air quality in surrounding communities. Real-time monitoring helps in early detection of increasing pollutant levels, aiding mitigation strategies in reducing smog formation, acid rain, and greenhouse gas emissions.

Regulatory Compliance and Risk Management

Glass production plants run under tight occupational and environmental controls. Air quality monitoring ensures that pollutant levels operate within threshold limit values (TLVs) and helps comply with the standards. Also, it provides recorded proof of compliance, which is important for audits and reporting.

Optimizing Operations

Monitoring data can also provide insights into process improvements, such as adjusting furnace temperatures, optimizing material handling, or identifying inefficient ventilation zones. This protects health and improves overall efficiency.

To summarize, air quality monitoring in glass manufacturing is not just an obligation, but a crucial requirement to ensure worker safety, environmental balance, regulatory compliance, and optimal efficiency.

How Can Glass Manufacturers Track Air Quality Effectively?

Efficient air quality monitoring is crucial for glass production since it ensures the workers’ health, ensures regulatory compliance, and reduces environmental impacts. For furnaces, Individual Section (IS) machines, batch houses, and storage areas with varied sources of emissions and high temperatures, continuous and accurate monitoring is required.

1. Real-Time Monitoring Systems

Modern production plants highly depend on real-time continuous AQM systems that can identify major pollutants like SPM, SO₂, NOx, CO₂, and VOCs. These systems can provide quick alerts about spikes in pollutant levels, enabling timely responses by increasing ventilation or managing furnace operations.

2. Strategic Installation of Sampling Stations

Monitoring efficiency relies on placing sensors at key locations: around furnaces, IS machines, storage areas, and exhaust pipes. Sampling stations should be placed based on airflow patterns and wind directions to sample fugitive emissions impacting employees and neighboring communities.

3. Continuous Data Collection and Analysis

Hourly or 8-hour periodic measurement helps in developing baseline air quality and tracing trends over time. Records can identify seasonal trends, changes in operating efficiency, or where emissions cross threshold limits.

4. Interfacing with Environmental Management Systems

Air quality monitoring should be linked to the plant’s environmental management system (EMS) to ensure a coordinated response. Automatic alerts, dashboards, and reports guarantee OSHA/NIOSH compliance with standards and local regulations.

5. Monitoring of Workers' Safety and Health

Measurements of pollutant concentrations from air quality systems can inform work-rest scheduling, heat stress protection, and the use of personal protective equipment (PPE), and prevent workers from being exposed to excessive concentrations of pollutants for extended periods.

By implementing these measures, glass producers can provide a safe, compliant, and environmentally friendly working environment while reducing emissions levels.

Best Practices for Planning & Implementing Air Monitoring

Proper planning and execution of air monitoring are critical for glass manufacturing plants to accurately measure pollutant levels, ensure worker safety, and comply with regulations. The best practices outlined below can lead to an effective air monitoring program:

1. Conduct a Comprehensive Site Survey

Before installing monitoring equipment, it is necessary to do a thorough site survey to pinpoint the emission sources, high-risk areas, and airflow directions. The main zones usually include furnaces, IS machines, batch houses, storage yards, and exhaust outlets. Knowing the layout provides representative coverage of the workplace.

2. Choose Appropriate Monitoring Equipment

Select instruments that can accurately measure SPM, SO₂, NOx, CO₂, VOCs, and heat parameters. High-volume samplers, continuous monitoring systems, and portable hand-held devices can be used depending on the location and measurement type. Equipment must align with national and international standards to make data trustworthy.

3. Set a Sampling Schedule

Sampling needs to be done at frequent intervals to record changes due to operational variations, production cycles, and seasonal influences. 8-hourly or hourly sampling is advisable in high-exposure zones, but less frequent measurements can be adequate in low-risk areas.

4. Installing Sensors at Key Points

Mount monitoring systems in areas of major worker exposures and ambient air conditions. Take wind direction, ventilation effectiveness, and possible accumulation points into consideration to avoid underestimating pollutant concentrations.

5. Data Handling and Analysis

Systematic collection and storage of monitoring data can help in trend analysis and reporting to regulators. Modern software applications can offer real-time alarms, dashboards, and predictive forecasts, allowing timely action for corrections.

6. Worker Training and Awareness

Workers should be informed about the reasons for monitoring and how monitoring procedures, work-rest cycles, and usage of protective gear work. This improves compliance and program effectiveness.

7. Routine Maintenance and Calibration

Monitoring equipment needs frequent maintenance and calibration to ensure accuracy and lifespan. Regular checks help in avoiding errors in readings that might risk worker safety or regulatory enforcement.

Adhering to these best practices, glass makers can establish a comprehensive air monitoring system that not only protects health but also maximizes operational efficiency and environmental stewardship.

Conclusion

Glass manufacturing plays a crucial role in modern life, yet it leaves a measurable mark on the air we breathe. The release of particulates, gases, and trace emissions affects both the health of workers and the quality of the surrounding environment. While regulatory standards and threshold limits provide guidance, the combined effect of these pollutants underscores the need for ongoing awareness and proactive measures. Implementing even basic air quality monitoring can help identify areas of concern, guide mitigation strategies, and promote safer workplaces. Equally important is fostering a culture of responsibility, where industry operations balance productivity with environmental stewardship. By understanding the scale of impact, acknowledging the risks, and adopting sensible interventions, glass manufacturers can protect human health, reduce environmental degradation, and contribute to a cleaner, safer atmosphere for everyone.