Summary

Air pollution from steel and iron manufacturing has been a major problem for a long time, especially as its effects range from environmental degradation to health impacts, which are now more pronounced than ever. Key pollutants such as PM₂.₅, SO₂, NOx, and VOCs are emitted at multiple stages of the production cycle, from raw material handling to sintering and smelting. Although traditional emission control methods exist, rising regulatory pressure has made compliance more complex, urging industries to rethink old practices.

Real-time air quality monitoring is coming up as a crucial solution to this challenge. It enables facilities to identify emission hotspots, make data-driven actions, and demonstrate commitment to sustainability. Modern monitoring solutions, when integrated with plant processes, can provide practical recommendations for compliance, transparency, and continuous improvement.

With rising global standards and tightening of environmental norms, adopting air quality monitoring isn’t simply a compliance measure, but a step toward operational optimization and sustainability in one of the most important industries in the world.

Air Quality Monitoring In Steel & Iron Plants

The Jharkhand State Pollution Control Board’s Clean Air Action Plan for Jamshedpur (Sept 2021) and a 2014 air quality study in Durgapur both found PM₁₀ and SO₂ levels above safe national standards, mainly driven by emissions from large iron and steel industries. Such frequent breaches not only raise non-compliance risks for industries but also endanger the health of workers and the public.

Monitoring major pollutants such as PM₂.₅, PM₁₀, SO₂, NO₂, CO, VOCs, and O₃ is crucial, since they arise from multiple process sources including sintering, coke ovens, blast furnaces, and raw material handling. Real-time data can help operators identify pollution hotspots, monitor emission patterns, and adjust processes to limit emissions.

Apart from meeting compliance standards, monitoring also supports transparency and contributes to long-term sustainability planning, helping the steel sector to operate responsibly in a strictly regulated and environmentally aware setting.

Why Air Pollution is a Growing Concern in Steel and Iron Plants?

Air pollution from iron and steel production is not a recent phenomenon; however, its effects have gained more ground than ever before. As production expands to satisfy industrial needs, volumes and intensities of emissions are on the rise. However, our idea has shifted regarding the extent to which these emissions impact public health, local ecosystems, and business sustainability.

Iron and steel industries emit a range of pollutants such as particulate matter (PM2.5 and PM₁₀), sulphur oxides (SOx), nitrogen oxides (NOx), carbon monoxide (CO), and heavy metals such as lead and chromium. These can result in chronic respiratory issues, cardiovascular hazards, and even neurological issues not only for the workers but also for the communities residing near industrial areas.

On the environmental side, pollution causes acid rain, smog, and degradation of nearby ecosystems. This is especially true in Indian steel belts like Jharkhand, Chhattisgarh, Odisha, and Maharashtra, where pollution levels have become high enough to cross safety limits regularly.

Adding to the stress is increasing awareness of climate targets, ESG requirements, and sustainable business practices. While aggressive regulatory enforcement has increased, the actual impetus today is the transparency of air pollution’s impact from satellite-monitored smog readings to hourly AQI alerts in industrial areas.

As governments call on investors to adopt cleaner operations, real-time air quality monitoring is no longer a choice. It’s a must-have tool for detecting hotspots of pollution, maintaining regulatory compliance, and guiding the industry toward cleaner operation.

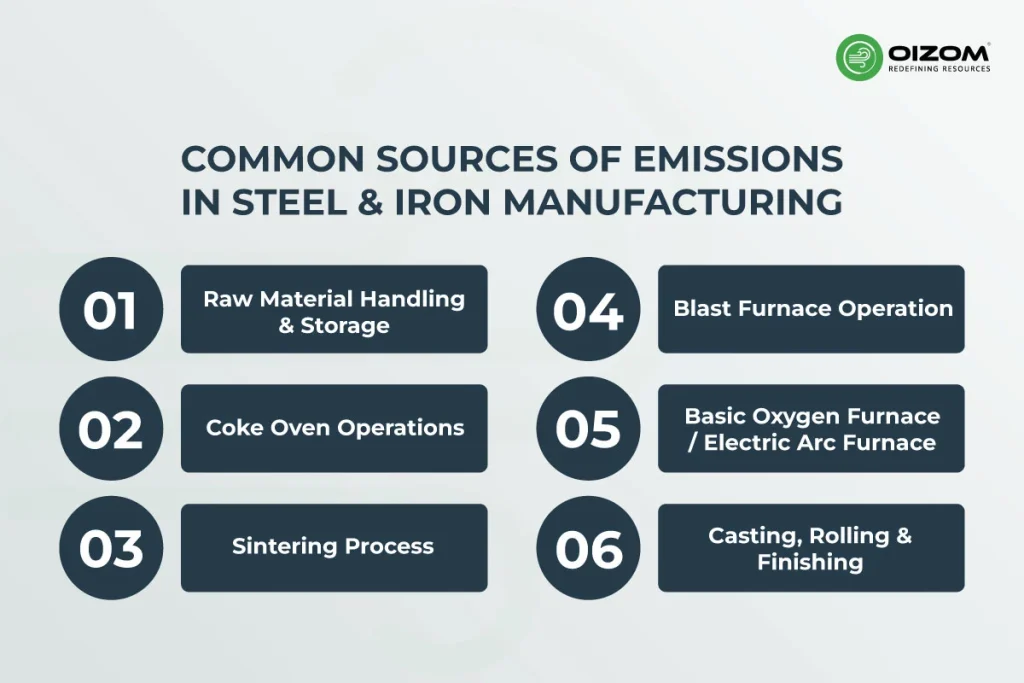

Common Sources of Emissions in Steel & Iron Manufacturing

Steel and iron manufacturing is an ordered process, where every step contributes to air pollution in a unique way through dust, gases, fumes, and heat releases. While some emissions can be observed (such as black smoke from stacks), others are not visible, but are still dangerous, such as poisonous gases and particulate matter.

An overview of where emissions commonly occur along the manufacturing process is provided below:

Raw Material Handling & Storage

Release of dust occurs during transportation, unloading, and storage of coal, iron ore, and limestone. Blown dust, such as particulate matter and material transfer, creates visible fugitive emissions, especially when systems are not provided with dust control.

Coke Oven Operations

Coke ovens (which produce coke from coal) emit poisonous smoke and fumes full of hydrocarbons, carbon monoxide, and particulate matter. Old, open-type coke ovens are particularly infamous for emitting carcinogenic substances such as benzene and PAHs (polycyclic aromatic hydrocarbons).

Sintering Process

The sintering operation, where the fine iron ores are smelted into a solid block, releases dust, sulfur compounds, and NOx gases. It is one of the most contaminating phases in integrated steelworks, particularly with the use of older sinter machines without emission devices.

Blast Furnace Operation

Iron ore is reduced with coke at high temperatures within the blast furnace. In this step, hot gas, carbon monoxide, and dust-laden fumes are emitted. Newer plants recover energy from blast furnace gas, but numerous old facilities still release huge amounts of energy without proper filtering.

Basic Oxygen Furnace (BOF) / Electric Arc Furnace (EAF)

These furnaces melt hot metal or scrap into steel. They turn out metallic fumes, fine particulate, and slag dust, notably on tapping and charging jobs. Emissions may surge when the quality of scrap is low or the temperature conditions are poor.

Casting, Rolling & Finishing

In steel shaping and cooling, the emissions are primarily thermal (steam and heat), with some localized dusting in grinding or cutting. Though less severe, they contribute to the overall air pollution burden.

Why These Emissions Matter

Such emissions, either visible or invisible, have a direct effect on the air quality in the vicinity of steel plants. Fumes, dust, and gaseous pollutants from industrial sources increase particulate matter (PM), which harms health. At the same time, gases like carbon monoxide (CO), nitrogen oxides (NOx), and volatile organic compounds (VOCs) lead to smog, acid rain, and chronic health issues. In areas still using older equipment without contemporary filtration and monitoring, the danger is escalated not only for the environment but also for the workers and local communities.

Regulatory Pressure and Compliance Challenges

With air quality worsening in the vicinity of industrial estates, government authorities in India and globally have reinforced emission standards, and the iron and steel industry is facing growing scrutiny. Where manufacturers long enjoyed a lack of oversight, today’s producers must confront a network of monitoring requirements, emission standards, and legal compliance.

In India, multiple environmental laws directly influence steel and iron mills:

- National Ambient Air Quality Standards (NAAQS): It establishes ambient standards for PM, SO₂, NOx, and other emissions in ambient air.

- Continuous Emission Monitoring Systems (CEMS): It’s required by the Central Pollution Control Board (CPCB) for major plants, involving real-time monitoring of pollutants from stacks.

- Environment Protection Act, 1986: The most important legal act supervising regulatory bodies to proceed against offenders.

- CPCB’s Charter for Sustainable Industrial Development: Emphasizes self-regulation, cleaner production, and industry-specific emission standards.

These guidelines came into existence due to increasing health issues, regular air pollution offenses, and India’s compliance with global environmental treaties. Non-compliance may result in fines, license revocation, or even facility closure.

Global Benchmarks and Their Influence

Countries like the European Union (EU) and the United States (US) have long enforced stringent emission norms through policies such as the EU Industrial Emissions Directive and the US EPA Clean Air Act. While India’s standards are evolving, these international frameworks set a benchmark that Indian industries are increasingly expected to follow, especially when exporting or attracting ESG-minded investors.

The Compliance Challenge

Despite the push for cleaner operations, compliance in steel and iron manufacturing is not straightforward. Plants face multiple challenges, including:

- Technological gaps: Many facilities still operate without modern filtration systems or calibrated CEMS equipment.

- Operational constraints: Installing emission control systems can be expensive, disruptive, and challenging to manage without skilled manpower.

- Data and reporting issues: Manual logs, unverified readings, and inconsistent data hinder meeting audit requirements or defending against violations.

This makes regulatory compliance a continuous effort, not a one-time fix.

The Way Forward

As enforcement becomes stricter, plants need real-time monitoring solutions that are accurate, automated, and audit-ready. Smart systems like Oizom’s air quality monitoring solutions can simplify compliance by offering real-time insights, secure data logging, and regulatory reporting tools, all while ensuring transparency and trust with stakeholders.

The Role of Real-Time Air Quality Monitoring in Steel and Iron Plants

With increasing regulatory pressure and health issues, real-time monitoring of air quality is imperative for today’s steel and iron facilities. It’s not a matter of complying with environmental standards; it’s about making your workplace safer, enhancing operational transparency, and cutting emissions at the source.

Steel production activities emit a wide range of airborne pollutants such as particulate matter (PM2.5 and PM₁₀), harmful gases like sulphur dioxide (SO₂), nitrogen oxides (NOx), carbon monoxide (CO), and volatile organic compounds (VOCs). Trace amounts of heavy metals are also emitted in some processes. These pollutants not only degrade the environment but also the health of workers and the nearby communities.

By including real-time air quality monitoring, steel mills can continue to assess the air pollution levels and take proactive steps. These systems assist in identifying hotspots at multiple stages of production, sounding alarms once limits are crossed, monitoring long-term trends for reporting to regulatory bodies, and determining inefficiencies leading to excessive emissions. Through this, they assist with regulatory audits and operational enhancements. For instance, Oizom’s real-time monitoring at the Tata Steel Jamshedpur plant tracked PM2.5, PM10, and SO₂, ensuring compliance and cleaner local air.

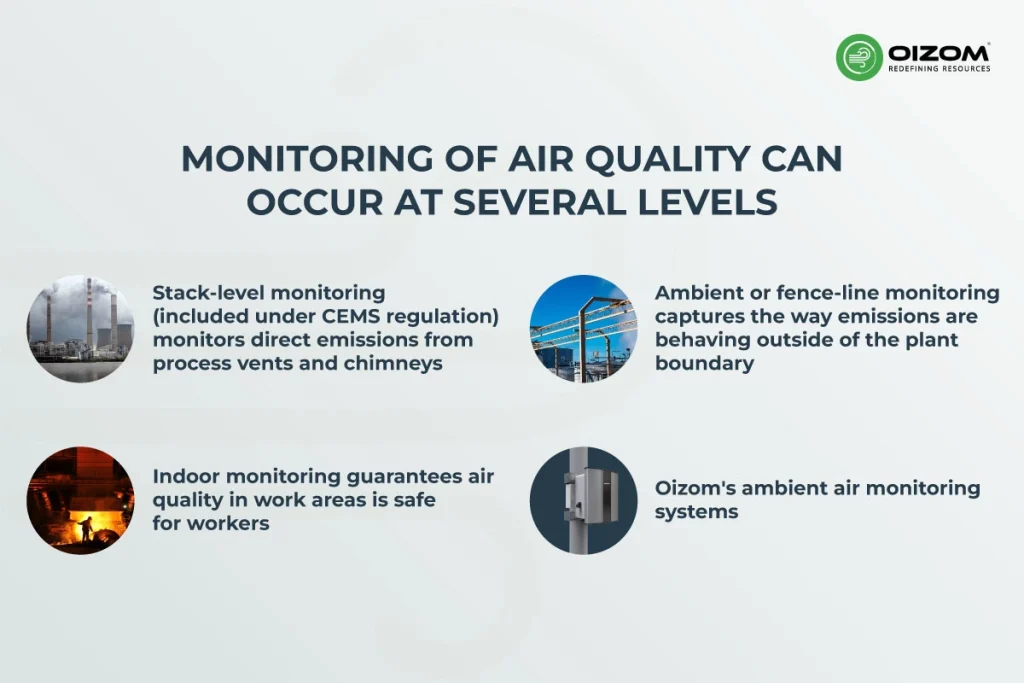

Monitoring of air quality can occur at several levels: stack-level monitoring (included under CEMS regulation) monitors direct emissions from process vents and chimneys; indoor monitoring guarantees air quality in work areas is safe for workers; and ambient or fence-line monitoring captures the way emissions are behaving outside of the plant boundary, where they impact the surrounding environment. Though each contributes, ambient monitoring is most critical to appreciating the plant’s actual effect on local air quality.

This is where Oizom’s ambient air monitoring systems prove their strategic value. Located at the plant perimeter, these compact and intelligent devices continuously monitor outdoor air quality in various parameters and measure environmental conditions such as wind speed, wind direction, temperature, and humidity, all of which impact how pollutants disperse.

By turning environmental data into actionable information, plants can establish automated alerts, create reports, and make data-driven decisions to run operations and enhance sustainability performance. With tighter regulations and increasing stakeholder awareness, real-time monitoring provides critical support for accountable and future-proof steelmaking.

How Oizom’s Air Quality Solutions Help Steel & Iron Plants?

Steel and iron manufacturing processes generate significant air pollution from particulate matter and toxic gases, as well as VOCs and odorous compounds. Oizom’s real-time ambient air quality monitoring systems help plants tackle these challenges with precision and ease.

By installing Oizom monitors at strategic locations such as the plant boundary, near slag yards, and close to high-emission zones, facilities can get continuous, location-specific insights into their environmental impact. These IoT-enabled systems measure PM2.5, PM10, SO₂, NOx, CO, and VOCs, along with meteorological parameters like wind speed and direction, enabling accurate source mapping and dispersion tracking.

Oizom’s cloud platform transforms this data into actionable dashboards, automated alerts, and regulatory reports. This empowers plant managers to take immediate action during emission spikes, optimize operations to stay within permissible limits, and build a culture of proactive compliance.

Moreover, having verifiable ambient air data helps plants strengthen transparency with stakeholders, support sustainability audits, and meet national and global environmental standards. With plug-and-play hardware, low maintenance, and scalable deployment, Oizom offers a reliable and future-ready solution for the steel and iron sector to manage air quality not just for compliance, but for long-term operational and environmental excellence.

Conclusion

Steel and iron factories irrefutably constitute the core of industrial growth, but simultaneously, they form a large percentage of the global air pollution load. As the environmental cost of emissions becomes increasingly impossible to disregard, particularly in the cases of industrial hotbeds such as India, no reliability can be afforded to data. Live monitoring of air quality is not merely a requirement for compliance anymore; it is a catalyst for tangible change.

Through the detection of emission patterns, regulatory compliance, and facilitating rapid responses to spikes in pollution, intelligent monitoring assists steel producers in achieving a more sustainable and productive balance. As evident through international benchmarks, those who invest in cleaner production today are well-prepared to meet tomorrow’s expectations from regulators, consumers, and investors.

With the latest ambient air monitoring technology, such as Oizom’s, industries can revolutionize the way they deal with pollution from being reactive to proactive. In today’s time, it’s not merely about compliance but about leading the path to a cleaner industrial future.