Summary of Blog

Ever wondered what’s floating around in the air of an automobile manufacturing plant? It’s more than just dust; think toxic VOCs from paint, ultrafine metal particles from welding, and gases like CO and NOx from engine testing. These aren’t just invisible threats; they directly impact worker health, equipment life, and your compliance checklist.

This blog breaks down what pollutants exist in each area (paint shop, welding zone, engine bay), which sensors work best (like PID for VOCs and NDIR for gases), and how real-time monitoring can turn raw data into action. You’ll also find practical strategies, like smart ventilation, predictive maintenance, and cloud dashboards, to help you stay safe, compliant, and efficient.

Whether you’re running EHS at a factory or just exploring monitoring options, this is your go-to guide to make sense of the air around your operations. It’s not just about what you build. It’s about the environment you build it in.

Air Quality Monitoring in Automobile Manufacturing

Ever walked through an automobile plant and wondered what’s in the air you’re breathing? It’s a simple question, but in an automobile manufacturing setup, the answer can be surprisingly complex. Automobile manufacturing isn’t just about precision engineering; it’s a hotspot for airborne pollutants. From paint booths to welding lines, each process releases a mix of VOCs, fine particulate matter (PM1, PM2.5), and gases like NOx and CO. These aren’t just regulatory headaches; they directly impact worker safety, product quality, and operational efficiency.

If you’re in the environmental monitoring space, you already know: real-time data is everything. But not all monitoring is created equal. A paint shop might need PID sensors to catch VOC spikes, while welding zones require laser-based PM monitors for ultrafine particles. Engine testing? That calls for NDIR or electrochemical sensors to track combustion gases accurately.

In this blog, we’ll break down the real-world air quality challenges inside automobile manufacturing plants. We’ll explore key pollutants, their sources, and the right monitoring technologies for each area. You’ll also get insights into system integration, whether you’re linking to SCADA, using 4- 20mA loops, or cloud-based platforms for predictive analytics and compliance reporting.

Whether you’re designing a new system or optimizing an existing one, this is your practical guide to smarter, standards-driven air quality monitoring in the automotive industry.

Why Air Quality Matters in Automobile Manufacturing?

It’s not just what comes off the assembly line that defines success. It’s also what’s in the air around it. In a typical automobile manufacturing setup, dozens of processes run in parallel, each releasing its own mix of pollutants. From paint fumes to metal dust, the invisible byproducts of production can have serious implications if not monitored and managed properly.

Worker Health and Safety

Let’s face it, an automobile plant is a hotspot for airborne hazards. From welding and grinding to painting and engine testing, each process exposes workers to a mix of metal fumes, VOCs (like toluene and xylene), and fine particulates (PM1, PM2.5, PM10). Without proper monitoring and ventilation, these pollutants can accumulate in confined areas, leading to respiratory issues, skin irritation, and even long-term health effects like occupational asthma and neurological damage.

Real-time air quality monitoring helps identify these risks before they become incidents. By tracking exposure levels with precision air quality monitoring devices, which have PID sensors for VOCs or laser-based sensors for particulates, facilities can protect their workforce while ensuring safer working conditions, especially in high-exposure zones like paint booths and welding lines.

Did you know this? Auto factory workers often report cough, breathlessness, and wheezing. A study in Tehran found significantly reduced lung function (FVC-Forced Vital Capacity, VC-Vital Capacity) in exposed workers, pointing to impaired breathing. In Mumbai, nearly 90% of spray painters reported respiratory issues, highlighting the real health risks of poor air quality on the shop floor.

Regulatory Compliance

Air quality isn’t just an internal concern. It’s a compliance mandate. Regulatory bodies like OSHA, CPCB, and frameworks such as ISO 14001 lay out strict exposure limits and documentation requirements for industrial pollutants. Failing to meet these standards can lead to fines, shutdowns, or worse, loss of credibility with clients and certification agencies.

With the right monitoring system, you’re not just checking a box; you’re building a defensible compliance strategy backed by timestamped, validated data that stands up in audits

Impact on Equipment and Processes

Poor air quality doesn’t just affect people. It wears down your machines, too. Corrosive gases and suspended particulates can infiltrate sensitive equipment, leading to contamination, downtime, and increased maintenance costs. In precision manufacturing, even a slight deviation caused by airborne interference can degrade product quality.

Were you aware of this? In motor vehicles, airborne dust isn’t just a nuisance. It can be harmful to the engine. When particles like silica and corundum enter the system, they cause faster wear on critical parts like piston rings, cylinder liners, crankshaft journals, valves, and bushings. These components play a key role in engine performance, and their wear directly affects the engine’s overall lifespan.

Emissions of pollutant compounds like sulfur dioxide and nitrogen oxides cause acid rain, which corrodes infrastructure and machinery.

Proactive air monitoring helps maintain cleaner environments, enhances equipment lifespan, and ensures smoother operations.

Common Air and Noise Pollutants in Automobile Manufacturing

Automobile manufacturing environments are filled with more than just mechanical noise and chemical smells; they’re often saturated with airborne pollutants that vary across processes. Understanding what’s in the air is the first step toward controlling it.

Particulate Matter (PM1, PM2.5, PM10)

Particulate matter, especially PM2.5 and smaller, is a major occupational hazard in automobile manufacturing and repair environments. These ultrafine particles, often generated during welding, sanding, grinding, and painting, are small enough to bypass the body’s natural defenses and lodge deep within the lungs.

In enclosed or poorly ventilated spaces, the risk increases significantly. Studies have shown that exposure to PM2.5 in vehicle repair shops can contribute to cellular damage and genotoxic effects, setting the stage for serious health conditions. Workers aren’t just exposed to dust; they’re also in contact with harmful substances like solvents, gasoline, benzene, polycyclic aromatic hydrocarbons (PAHs), and heavy metals such as zinc (Zn), cadmium (Cd), nickel (Ni), and lead (Pb).

These exposures are among the worst recorded in occupational settings, with strong links to chronic diseases including asthma, allergic rhinitis, cardiovascular disorders, and even certain types of cancer.

That’s why real-time monitoring of particulate matter across all three size categories, PM1, PM2.5, and PM10, is crucial in automobile plants. Laser-based PM sensors offer accurate detection and help maintain safe working conditions, especially in high-risk zones like body shops and paint booths.

Concerned about monitoring PM1, PM2.5, and PM10 in your automobile manufacturing plant? You’re not alone, and you’re not without a solution.

With Oizom Dustroid, you get a comprehensive, reliable system for real-time dust monitoring design for industrial environments. Whether it’s PM1, PM2.5, or PM10, Dustroid helps you stay ahead of regulatory limits and workplace safety standards.

Designed specifically for industries like automobile manufacturing, it supports a wide range of network connectivity options, including GSM, Ethernet, and LoRa, and offers on-device data storage of up to 8 GB, ensuring you never miss critical data, even in case of network downtime.

If you’re looking for accurate, scalable, and hassle-free PM monitoring, Dustroid is your one-stop solution.

Volatile Organic Compounds (VOCs)

Used in paints, thinners, adhesives, sealants, and cleaning agents, VOCs like toluene, benzene, ethylbenzene, and xylene (BTEX group) are highly toxic and often flammable. Prolonged exposure can lead to neurological, liver, and kidney issues. VOC concentrations are often highest in spray booths and paint shops. PID sensors are ideal for detecting them due to their sensitivity to low-level concentrations.

If you’re dealing with BTEX compounds (benzene, toluene, ethylbenzene, and xylene), you know how important it is to monitor them accurately. These volatile compounds are often present in automobile manufacturing units and can pose serious health and environmental risks if left unchecked.

To address this, Oizom has integrated a dedicated BTEX sensor into its range of environmental monitoring devices. Known for their modular design and real-time data capabilities, Oizom devices now offer reliable detection of BTEX compounds, helping the automotive industry to gain deeper insights into enclosed air quality and take timely action where needed.

Gaseous Pollutants

Combustion engines, curing ovens, and generator sets emit carbon monoxide (CO), nitrogen oxides (NO, NO₂), sulfur dioxide (SO₂), and ozone (O₃). These gases can cause dizziness, respiratory issues, corrosion, and even explosive risks in poorly ventilated areas. Monitoring with electrochemical, NDIR, or UV-based sensors ensures accurate detection.

Noise and Microclimate Factor

Air quality monitoring doesn’t stop at gases and particles; microclimate conditions and noise also play a critical role in understanding environmental dynamics inside an automobile plant.

Heat, humidity, air pressure, and airflow directly influence gas behavior and sensor accuracy. For instance, high humidity can increase VOC volatility, making concentrations appear higher than they are, while poor ventilation may cause pollutants to accumulate in localized zones.

Similarly, noise pollution, often overlooked in air quality studies, can be a key occupational hazard. Common sources inside auto manufacturing facilities include:

- Pneumatic tools

- Welding stations

- Hydraulic presses

- Compressor units

- Robotic arms

- Engine testing bays

Prolonged exposure to high decibel levels not only affects worker health but can also interfere with sensor signals or acoustic-based monitoring systems.

To ensure data accuracy and enable predictive ventilation strategies, it’s essential to continuously monitor temperature, relative humidity (RH), airflow, and noise levels. This layered approach supports better sensor calibration, smarter environmental control, and more informed health and safety decisions on the shop floor.

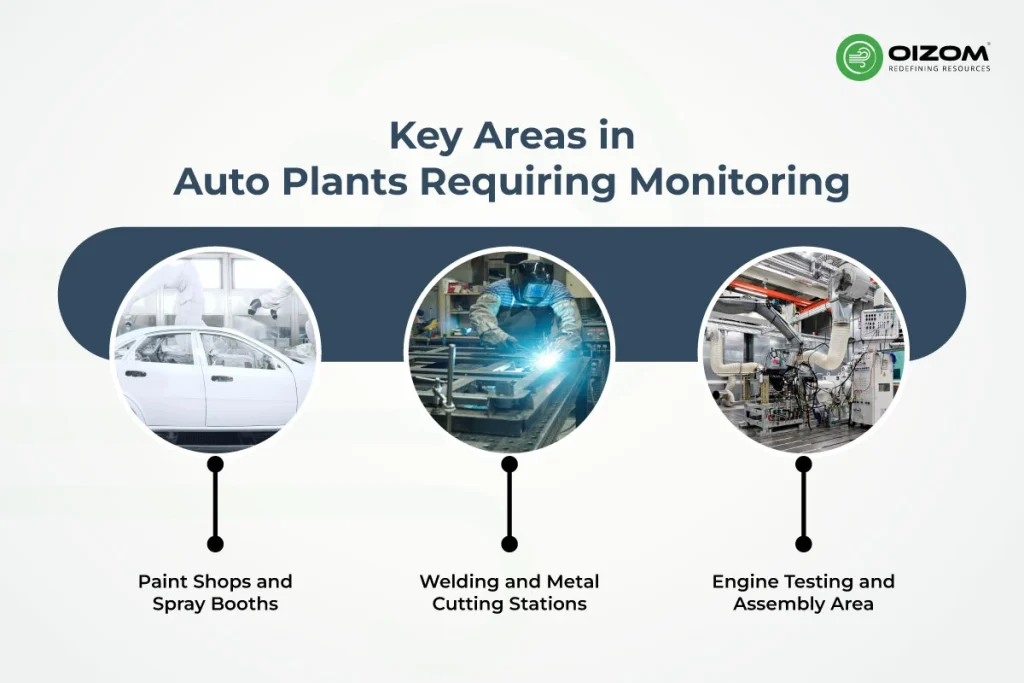

Key Areas in Auto Plants Requiring Monitoring

Not all corners of an automobile plant are created equal when it comes to air quality risks. Certain zones are far more prone to emissions, making targeted monitoring essential, not just for compliance, but also for operational safety and process optimization.

Paint Shops and Spray Booths

Paint booths are among the highest VOC emission zones in the plant. Solvents in paints, primers, and thinners release harmful compounds like toluene, xylene, and benzene, many of which are volatile and flammable.

Without proper monitoring, these VOCs can accumulate quickly in enclosed spaces, leading to health risks, fire hazards, and poor indoor air quality. That’s why continuous VOC tracking using PID sensors is crucial. Monitoring should be paired with smart ventilation systems that adjust airflow based on real-time pollutant levels, ensuring exposure stays below occupational thresholds.

Welding and Metal Cutting Stations

Welding, cutting, and grinding activities generate aerosols of ultrafine metal particulates, including iron, manganese, chromium, and nickel. These are not just respiratory irritants; they pose long-term health risks like metal fume fever and lung damage.

When metals are machined or cut, like during engine part production, metalworking fluids (MWFs) are often used to cool and lubricate the process. But these fluids can turn into a fine mist in the air, which workers can breathe in. Long-term exposure to this mist has been linked to serious health issues like hypersensitivity pneumonitis (a type of lung inflammation caused by the immune system), as well as chronic bronchitis and asthma.

Did you know? In 2020, over 420,000 people in the U.S. were working in metal-related jobs, according to the Bureau of Labor Statistics. Out of them, around 2,000 cases of metal fume fever were reported. What’s more, it’s not just full-time welders at risk; even plumbers, pipefitters, and others who weld occasionally can be affected by exposure to metal fumes.

Because these particles are highly localized, real-time PM1 and PM2.5 monitoring near the source is essential. Installing fume extraction systems with localized monitoring helps minimize worker exposure and prevents particulates from spreading to adjacent work zones. Some modern systems even trigger extraction fans automatically based on particulate thresholds.

Engine Testing and Assembly Area

Engine testing bays and some assembly lines are hotspots for combustion emissions, including CO, NOx, and unburned hydrocarbons. These zones are often semi-enclosed, amplifying the risk of gas buildup if ventilation isn’t well-optimized.

Deploying electrochemical or NDIR sensors enables accurate tracking of combustion gases in real time. Monitoring systems in these zones should be tightly integrated with exhaust handling units and SCADA systems to trigger alarms, enhance ventilation, or shut down equipment if limits are breached.

In one example, Sud-Chemie, a company that makes catalytic control systems, used real-time air quality monitoring to ensure worker safety and meet environmental regulations in critical areas of their facility. The system’s ability to connect with SCADA made it easier to manage air quality without affecting day-to-day operations. (Read the full case insight here.)

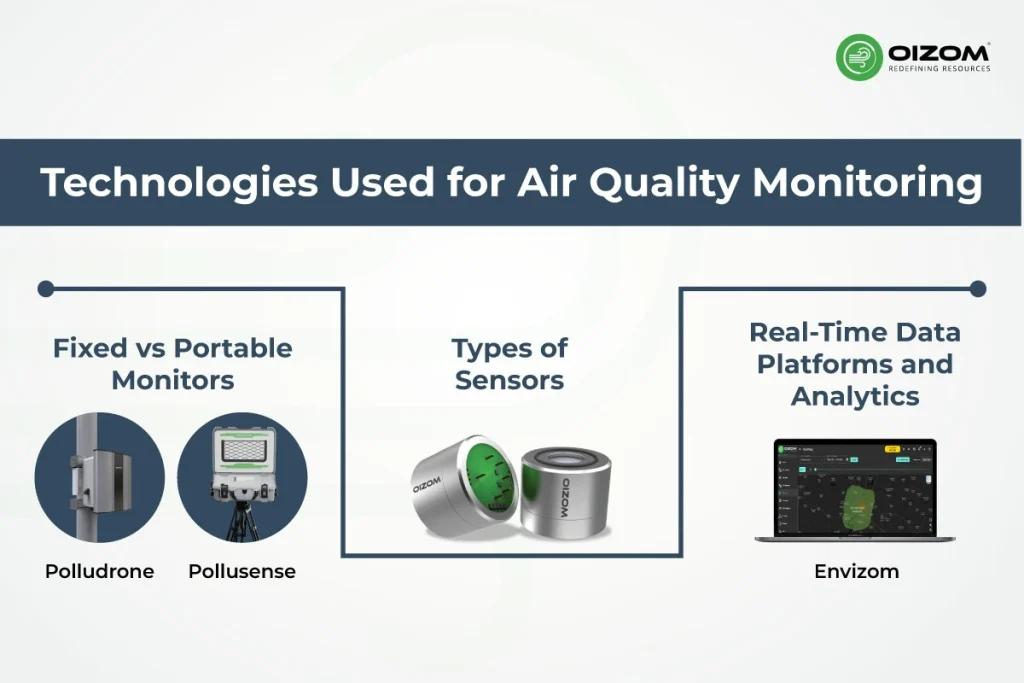

Technologies Used for Air Quality Monitoring

Modern air quality monitoring in automobile manufacturing is no longer just about collecting data. It’s about collecting the right data, in real-time, and acting on it. Whether you’re focused on compliance, health, or process optimization, the technology you choose matters.

Fixed vs Portable Monitors

Fixed monitors are great for continuous, long-term monitoring. They’re usually installed in high-risk zones like paint booths or engine testing bays to track trends and trigger automated responses.

Portable monitors, on the other hand, offer flexibility. They’re perfect for spot assessments, compliance checks, or temporary setups during maintenance or commissioning activities. However, they typically have limited power backup and may not cover large areas unless redeployed frequently.

For a balanced monitoring strategy, many facilities use a hybrid approach, fixed units for ongoing compliance, and portable units like Pollusense for mobile audits.

Types of Sensors

Different pollutants call for different technologies:

- PID sensors for detecting VOCs in spray booths.

- NDIR sensors for accurate CO₂ or CO measurements during combustion testing.

- Optical (laser scattering) sensors for real-time PM1, PM2.5, and PM10 detection.

Sensor selection must consider response time, cross-sensitivity, calibration needs, and environmental conditions like humidity and temperature.

But choosing the right sensor doesn’t stop at pollutant type. You also need to consider the following:

- Response Time: This refers to how quickly a sensor detects a change in pollutant levels. In dynamic environments like spray booths or welding zones, a fast response time (within seconds) is crucial to catch sudden spikes and trigger ventilation systems in time.

- Cross-Sensitivity: Some sensors may react to more than just their target gas. For example, an electrochemical sensor designed for NO₂ may show false readings if ozone is present. Choosing sensors with minimal cross-sensitivity or using algorithms to correct interference improves accuracy.

- Calibration Needs: Over time, sensor readings can drift. Regular calibration using certified reference gases or gravimetric methods ensures that data remains reliable, especially important in regulated environments where decisions depend on threshold limits.

- For example, VOC sensors are typically calibrated using standard gases to match real-world conditions. At Oizom, calibration follows strict international guidelines like the USEPA’s 40 CFR Part 53 and the EU’s 2008/50/EC directive, ensuring both reliability and regulatory alignment. This level of precision is especially important when air quality data is used for compliance, reporting, or health-based decision-making.

- Environmental Conditions: Temperature, humidity, and pressure can impact sensor performance. For instance, high humidity can alter VOC readings or cause condensation in optical sensors. It’s essential to choose sensors with built-in compensation algorithms or pair them with environmental monitoring to apply corrections.

Real-Time Data Platforms and Analytics

Monitoring is only as powerful as the insights it delivers. That’s where Envizom, Oizom’s cloud-based data platform, steps in. It provides real-time dashboards, heatmaps, alerts, and trend analysis, making it easier for plant managers and EHS teams to spot issues, track compliance, and optimize ventilation systems.

Integrated with SCADA, EMS, or Building Management Systems, Envizom ensures your air quality data becomes actionable intelligence.

Strategies to Improve Air Quality

Monitoring air quality is only the first step; what truly matters is how you act on that data. In automobile manufacturing plants, where emissions come from multiple sources and processes, a well-rounded strategy that combines source control, smart ventilation, and predictive maintenance can significantly reduce health risks and operational disruptions.

Source Control

The most effective way to improve air quality is to minimize emissions at their origin. This starts with selecting low-emission materials, such as water-based paints, low-VOC adhesives, and clean-burning fuels. Implementing closed-loop systems in paint booths or solvent-handling areas helps prevent the release of harmful compounds into the workspace.

By addressing emissions at the source, facilities reduce the overall pollutant load, lowering the burden on ventilation systems and improving indoor air quality right at the point of generation.

A practical example of this can be seen in Amara Raja Energy & Mobility Ltd., where real-time particulate monitoring played a key role in identifying dust-generating activities. This allowed their team to implement targeted process improvements at the source, enhancing both air quality and operational efficiency. (Read the full case study here.)

Ventilation and Filtration Systems

Even with source control, pollutants like VOCs and particulate matter can stay in the air, especially in enclosed zones like welding booths and engine testing areas. Effective ventilation systems equipped with HEPA filters for particulate matter and activated carbon filters for VOCs are essential.

Maintaining proper air exchange rates is equally important. Too low, and pollutants build up; too high, and energy efficiency drops. Dynamic ventilation systems that respond to real-time air quality data ensure a balanced environment where safety and efficiency go hand in hand.

Predictive Maintenance and Automation

Poor air quality isn’t always about external factors. It can be a sign of internal issues like clogged filters, malfunctioning fans, or blocked exhausts. That’s where predictive maintenance makes a difference.

By continuously monitoring environmental parameters and equipment performance, facilities can anticipate failures before they happen. Integration with SCADA or EMS platforms allows for automated alerts, ventilation adjustments, and maintenance scheduling, turning reactive responses into proactive interventions.

Conclusion

Air quality in automobile manufacturing is more than a compliance checkbox. It’s a key factor in ensuring worker health, product quality, and operational efficiency. From PM1 and VOCs to combustion gases like CO and NOx, each pollutant requires targeted monitoring using the right sensor technology, PID for VOCs, NDIR for gases, and optical sensors for particulates.

Implementing real-time monitoring, integrating it with SCADA or EMS systems, and acting on insights through source control, smart ventilation, and predictive maintenance are no longer optional; they’re essential.

Looking ahead, the future of air quality management in the auto industry lies in AI-driven analytics, sensor fusion, and automated control systems that don’t just detect but predict and prevent air quality issues before they impact people or processes.

As manufacturing evolves, so must our approach to environmental safety, data-backed, proactive, and built for scale.