Summary

Wastewater treatment plants (WWTPs) do much more than clean water; they also influence the air we breathe. As wastewater is processed, gases like methane (CH₄), hydrogen sulfide (H₂S), ammonia (NH₃), carbon dioxide (CO₂), and volatile organic compounds (VOCs) are released into the atmosphere. These emissions, often invisible, contribute to climate change, local air pollution, and health risks for workers and nearby communities.

From biological and chemical treatment to sludge handling, each stage of wastewater processing can become a source of air pollutants. Without proper controls, odorous and hazardous gases can escape into the environment, impacting both people and the planet.

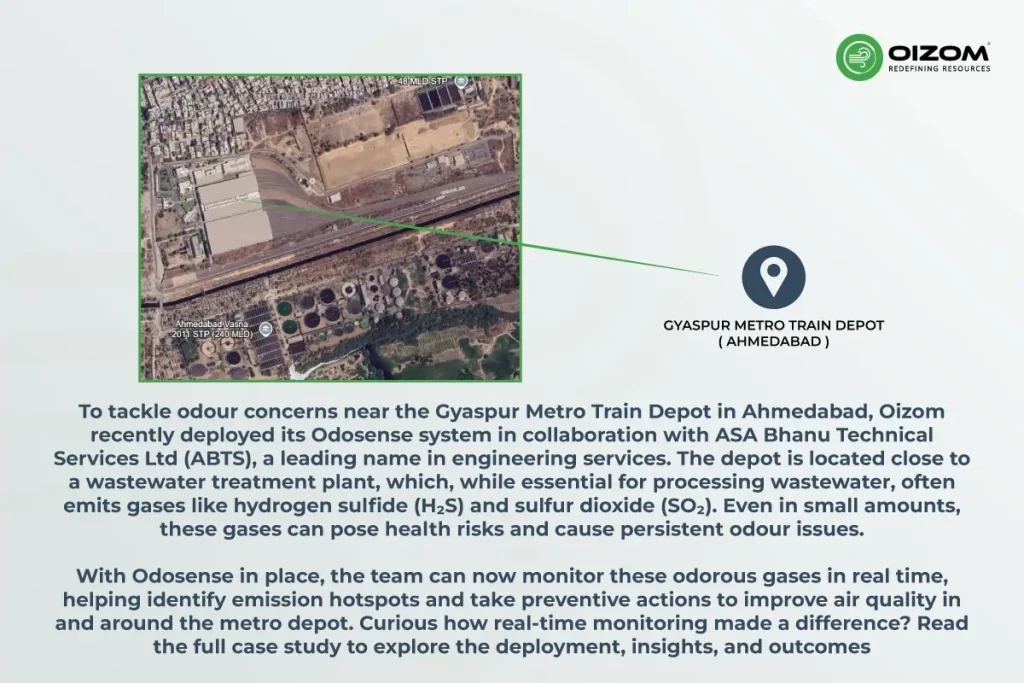

To manage this, WWTPs are turning to real-time air quality monitoring, IoT-based gas sensors, and predictive analytics. Solutions like Oizom’s Odosense and BTEX sensors are enabling more accurate detection of trace gases, helping facilities act quickly and stay compliant.

Global regulations, like those from the USEPA, EU, and CPCB, are pushing for stricter monitoring and emission limits. However, the path forward also depends on industry best practices, community engagement, and transparent reporting. As we move toward smarter and more sustainable systems, it’s clear that air quality should be just as much a part of wastewater management as water itself. After all, clean water shouldn’t come at the cost of dirty air.

Emissions from WWTP: A Growing Air Quality Concern

Think wastewater only affects water? Think again. Behind the scenes of every wastewater treatment plant (WWTP), there’s a lesser-known story unfolding, one that rises into the air, not flows into the drains. As wastewater is processed, a range of gases, like hydrogen sulfide (H₂S), methane (CH₄), ammonia (NH₃), and volatile organic compounds (VOCs), can be released into the atmosphere, posing risks to both human health and the environment.

These emissions often originate from biological treatment, chemical dosing, and sludge management processes. While their odour is usually the first thing people notice, the long-term impact goes beyond discomfort. Did you know this? Odour annoyance is a significant source of environmental complaints worldwide, accounting for over 60% in some countries. Especially when gases like methane add to the greenhouse effect, or H₂S causes respiratory issues in surrounding communities.

With increasing focus on sustainable operations and regulatory compliance, it’s now essential for WWTP operators, researchers, and policymakers to monitor air emissions just as closely as water discharge. Thankfully, advancements in real-time air quality monitoring and smart gas sensors have made it easier to detect and mitigate these emissions.

In this blog, we’ll explore the science behind WWTP air emissions, the key pollutants involved, and how modern monitoring solutions can help industries stay compliant while protecting public health.

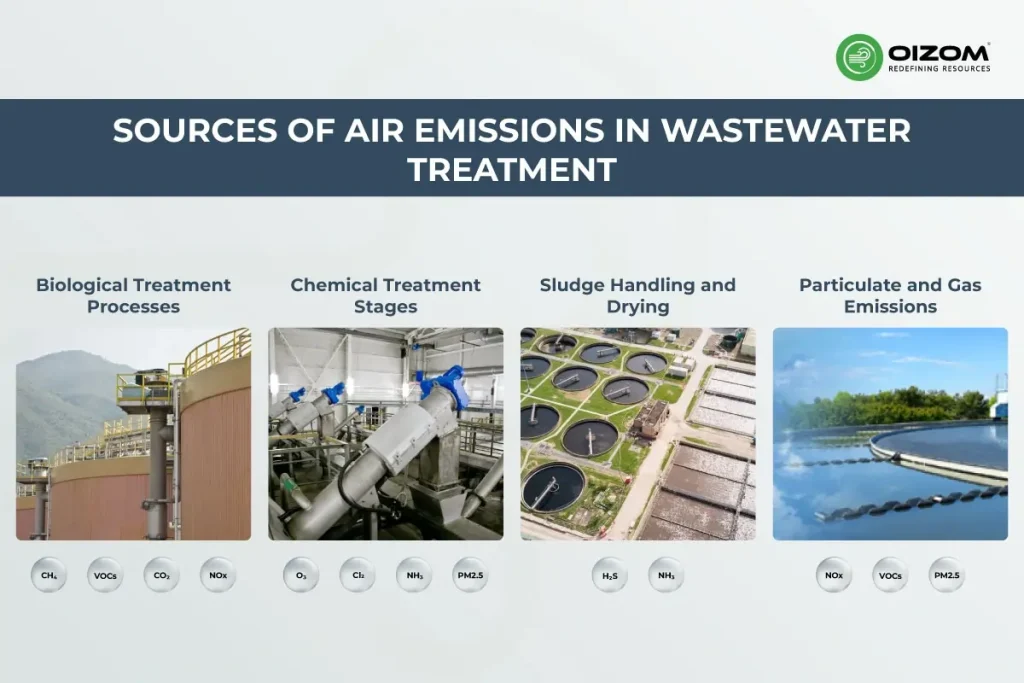

Sources of Air Emissions in Wastewater Treatment

When we think of wastewater treatment, air pollution isn’t always top of mind, but it should be. Several treatment processes unintentionally release gases that contribute to local air quality degradation and greenhouse gas emissions. Among the primary sources are biological treatment stages, especially those involving anaerobic conditions. Did you know? According to recent research, WWTPs may be anthropogenic GHG emission sources that contribute to air pollution and climate change.

Biological Treatment Processes

Anaerobic digestion is a common process used to break down organic matter in sludge without oxygen. While it’s efficient and often used to produce energy-rich biogas, it also releases methane (CH₄) and carbon dioxide (CO₂), both potent greenhouse gases. Methane, in particular, is over 25 times more effective than CO₂ at trapping heat in the atmosphere over a 100-year period. If not properly captured, leaks from digesters, pipelines, or storage units can lead to significant air quality concerns.

During biological treatment, especially in aeration tanks and sludge storage. VOCs are emitted due to the breakdown of organic substances. These compounds can react with nitrogen oxides (NOx) in sunlight to form ground-level ozone, a harmful air pollutant. Some VOCs are also hazardous air pollutants (HAPs), with potential health effects ranging from eye irritation to long-term respiratory issues.

According to 40 CFR Part 63, Subpart VVV, the U.S. regulation allows only a small amount, 0.014, of the total hazardous air pollutants (HAPs) to be discharged into wastewater treatment plants on an annual average. In California, under Rule 1176 by the Environmental Protection Agency, industries like petrochemical and chemical plants must ensure that:

- VOC emissions from wastewater systems stay below 500 ppm,

- Primary treatment units are closed systems, and

- Water entering the treatment plant contains no more than 5 mg/L of VOCs.

These rules aim to control harmful gas releases and protect air quality around treatment facilities.

Chemical Treatment Stages

Chemical treatment plays a crucial role in disinfecting wastewater, but it also comes with its own set of air quality challenges.

Use of Chlorine, Ozone, and Ammonia

Disinfectants like chlorine, ozone (O₃), and ammonia are commonly used to neutralize pathogens. However, when these chemicals react with organic matter in the water, they can release harmful byproducts into the air.

- Chlorine can form chlorinated VOCs and trihalomethanes (THMs), some of which are carcinogenic.

- Ozone, while effective, is a reactive gas that can escape into the atmosphere if not fully consumed, contributing to oxidative smog.

- Ammonia, often used in chloramination, can volatilize and release NH₃ gas, which is a respiratory irritant and contributes to secondary particulate formation (PM2.5).

These emissions are often overlooked but can pose serious health risks in confined plant environments and surrounding communities. Proper dosing, closed systems, and real-time gas monitoring are essential to minimize these air pollutants and ensure safe operations.

Sludge Handling and Drying

Sludge management is one of the most emission-intensive stages of wastewater treatment, and often the most noticeable.

Odour Issues from Sludge Dewatering

During dewatering, sludge is separated from water using centrifuges, belt presses, or drying beds. This process often releases foul-smelling gases, primarily hydrogen sulfide (H₂S) and ammonia (NH₃). These gases not only create odour nuisances but are also toxic in high concentrations, affecting worker safety and surrounding communities.

That’s where solutions like Oizom’s Odosense come in. Designed specifically for odour and gas monitoring, Odosense uses electrochemical sensors for precise detection of H₂S and photoionization detectors (PID) to accurately measure VOC levels, even at low concentrations.

What sets Odosense apart is its 3-level calibration process, which includes factory calibration, multi-span calibration, and collocation calibration, all aligned with U.S. EPA guidelines. This ensures highly accurate and reliable data, crucial for maintaining compliance and addressing community concerns.

With real-time monitoring, plant operators can take timely action to mitigate odour and emissions before they escalate into bigger problems.

Particulate and Gas Emissions

When sludge is dried, whether by heat, air-drying, or thermal processes. It releases fine particulates and volatile organic compounds (VOCs) into the air. Thermal drying, in particular, can emit nitrogen oxides (NOx) and sulfur compounds, which contribute to smog formation and acid rain.

Without proper enclosures or scrubbers, these emissions can quickly exceed regulatory thresholds and create serious environmental and health risks. Using covered systems, biofilters, and real-time gas monitors can help control and reduce these emissions while maintaining operational compliance.

Key Pollutants Released from WWTPs

Each day, domestic households produce 200- 300 L of wastewater per person on average. That’s not even factoring in solid waste. There are various air pollutants which are released from WWTPs across various stages while treating the wastewater.

Hydrogen Sulfide (H₂S)

Commonly produced during anaerobic digestion and sludge handling, H₂S is notorious for its rotten egg smell. But it’s not just unpleasant, it’s toxic at high concentrations and corrosive to equipment. Even at low levels, long-term exposure can irritate the eyes, throat, and respiratory system. Continuous monitoring of H₂S is critical, especially near sludge processing zones.

Sulfide in wastewater exists in three forms: hydrogen sulfide gas (H₂S), and two non-gaseous forms, hydrogen sulfide ions (HS⁻) and sulfide ions (S²⁻). The amount of each form depends on the conditions in the water.

H₂S gas is mainly produced in slimy layers that build up on the inside of pipes and in the sludge at the bottom of clarifiers and other solids treatment units. The rate at which sulfides form depends on several factors, including the levels of sulfate, organic material, and dissolved oxygen, as well as pH, temperature, how long the water stays in the system, flow speed, and the surface area available for reactions.

Were you aware of this? Breathing in hydrogen sulfide (H₂S), even at low levels, can be harmful. If you’re exposed to 2–5 ppm for a long time, it may cause nausea, watery eyes, headaches, and trouble breathing. At levels above 20 ppm, symptoms can worsen, leading to fatigue, loss of appetite, irritability, and dizziness.

Once the concentration reaches 100–150 ppm, your nose can no longer detect the smell, making it even more dangerous. And at levels over 500 ppm, H₂S can cause serious eye damage, unconsciousness within minutes, and can even be fatal, according to OSHA.

Methane (CH₄) and Carbon Dioxide (CO₂)

These greenhouse gases are byproducts of organic matter breakdown in anaerobic conditions. While methane can be captured for energy use, leaks are common and dangerous. Methane is over 25 times more potent than CO₂ in trapping heat in the atmosphere, making it a significant climate concern. CO₂, although less potent, is released in large volumes and contributes to cumulative emissions. CH4 is mainly produced and emitted through leakage in anaerobic process stages (anaerobic sludge treatment).

According to the U.S. Environmental Protection Agency (US EPA), centralized domestic wastewater treatment, including processes like anaerobic sludge digestion, produces about 250,000 tonnes of methane (CH₄) each year. That’s equal to around 6.3 million metric tons of CO₂ in terms of climate impact. This makes up about 14% of methane emissions from waste in the U.S., and 1% of the country’s total human-caused methane emissions.

Carbon Dioxide (CO2)

When we think about emissions from wastewater treatment plants, carbon dioxide (CO₂) often gets overlooked, but it plays a big role in the facility’s carbon footprint.

CO₂ is mainly produced during aerobic biological treatment, where microbes break down organic matter using oxygen. In the process, they release CO₂, just like humans do when we breathe. While CO₂ isn’t directly harmful at typical concentrations, it’s one of the primary greenhouse gases contributing to global warming.

In large, centralized wastewater systems, this release happens constantly, especially from aeration tanks, biological reactors, and sludge stabilization units. And while each puff of CO₂ might seem small, it adds up over time.

That’s why it’s becoming increasingly important to monitor CO₂ emissions as part of a broader sustainability strategy. When facilities track both CO₂ and methane, they get a clearer picture of their total climate impact.

Volatile Organic Compounds (VOCs)

Volatile Organic Compounds (VOCs) are a large group of carbon-based chemicals that easily evaporate at room temperature, and they’re a major source of air pollution in wastewater treatment plants.

VOCs are released during chemical dosing, biological treatment, and especially during sludge drying. Many VOCs react with sunlight and nitrogen oxides (NOx) to form ground-level ozone, a major component of smog. Some are classified as hazardous air pollutants (HAPs) because they can cause health problems like eye and throat irritation, headaches, and even damage to the liver, kidneys, and nervous system. A few VOCs are even known to be carcinogenic.

Common VOCs found in wastewater systems include toluene, benzene, chloroform, xylene, and ethylene glycol. These chemicals often evaporate into the air, especially during aeration processes, where the wastewater is exposed to air to support microbial activity. The open surfaces of tanks and sludge beds make it easy for VOCs to escape into the environment.

Weather conditions play a big role. On hot, sunny, or windy days, the evaporation of VOCs increases, spreading pollutants farther from the plant. That’s why summer months often see higher VOC emissions. To manage these risks, continuous monitoring of VOC is essential. Also, oxygen control is critical, not just for treatment efficiency but also to help reduce unwanted chemical emissions.

Ammonia (NH₃)

Ammonia (NH₃) is widely used in industries and agriculture, but it’s also a common pollutant in wastewater. It can easily become airborne, especially during open tank treatments or sludge dewatering, and often causes eye and respiratory irritation. More importantly, when it reacts in the atmosphere, it contributes to PM2.5 formation, adding to air pollution.

In wastewater treatment, ammonia is usually removed through biological processes that convert it into harmless nitrogen gas. But when the system is overloaded, due to high volumes of industrial wastewater or organic matter, ammonia removal becomes less effective, leading to emissions that are harder to control.

While agriculture is the largest known source of ammonia, there’s still a lot of uncertainty around how much is emitted from non-agricultural sources, like wastewater treatment plants.

To support better monitoring, Oizom has introduced a new low-range ammonia sensor that can detect concentrations as low as 15 parts per billion (ppb). This makes it especially useful in wastewater applications, where even small amounts of ammonia need to be closely tracked for compliance and environmental safety.

Health and Environmental Impacts

Air emissions from wastewater treatment plants don’t just stay within plant boundaries; they can affect human health and the broader environment.

Effects on Human Health

Wastewater treatment processes release a mix of gases, like hydrogen sulfide (H₂S), ammonia (NH₃), and volatile organic compounds (VOCs), that can affect human health even at low concentrations. Hydrogen sulfide, for instance, is known for its strong rotten egg smell, but beyond the odour, it can cause eye irritation, headaches, nausea, and breathing difficulties with continued exposure.

Ammonia can irritate the skin, eyes, throat, and lungs, especially for plant workers or nearby residents exposed over time. In higher concentrations, it can trigger asthma-like symptoms and worsen existing respiratory conditions.

VOCs are particularly concerning because many are classified as hazardous air pollutants (HAPs). Short-term exposure can lead to dizziness, fatigue, and allergic reactions, while long-term exposure to certain VOCs like benzene or toluene may increase the risk of organ damage and even cancer.

Odorous gases can also affect mental well-being, contributing to stress, sleep disturbances, and reduced quality of life for people living near treatment plants. In communities with prolonged odour issues, there have been reports of psychosocial impacts, including increased anxiety and social isolation.

Contribution to Greenhouse Gases

Wastewater treatment plants release methane (CH₄) and nitrous oxide (N₂O), two of the most powerful greenhouse gases. Methane traps 25 times more heat than carbon dioxide (CO₂), and nitrous oxide is nearly 300 times stronger. These gases are mostly released during anaerobic digestion, sludge stabilization, and nutrient removal processes, making WWTPs a noteworthy contributor to climate change.

Globally, wastewater treatment is recognized as a source of GHG emissions, particularly CO₂, CH₄, and N₂O. In the European Union, these emissions are officially reported under the UN Framework Convention on Climate Change (UNFCCC).

According to UNFCCC estimates from 2018, industrialized countries reported that methane from wastewater made up 3.6% of their total greenhouse gas emissions (in CO₂-equivalent), while nitrous oxide contributed 2.6%. This highlights the important role that WWTP operations play in both air pollution and climate impact.

Air Quality Monitoring Solutions in WWTPs

Managing air emissions in wastewater treatment plants (WWTPs) requires more than just treating water. With gases like methane, hydrogen sulfide, ammonia, and VOCs commonly present, air quality monitoring is now a key part of plant operations, both for environmental compliance and for protecting health.

Real-time Monitoring Devices

Today’s WWTPs rely on real-time air quality monitoring systems to detect and quantify air pollutants as they are emitted. Devices equipped with electrochemical sensors (for H₂S, NH₃), NDIR sensors (for CO₂), MPS sensors (for CH₄), and PID sensors (for VOCs) can detect pollutants at very low concentrations, often down to parts per billion (ppb) levels.

These sensors are installed in critical zones like aeration tanks, sludge treatment areas, and chemical dosing units. Data collected from these sensors can be visualized on cloud-based platforms, enabling remote diagnostics, automated alerts, and trend analysis. Integration with SCADA or PLC systems ensures seamless communication across the plant’s control architecture.

By providing early warnings, these monitoring devices help operators respond quickly, whether it’s increasing ventilation, adjusting process parameters, or activating scrubbing systems, before emissions escalate to unsafe or non-compliant levels.

Odour Control and Gas Detection Systems

Beyond detection, odour control systems play a critical role in emission management. Technologies such as:

- Wet scrubbers use chemical or water-based solutions to absorb gases like H₂S and NH₃.

- Biofilters use microbial action to break down odorous gases into harmless byproducts.

- Activated carbon filters physically trap VOCs and other organics from the air stream.

Paired with real-time air quality monitoring devices across multiple locations, these systems enable zone-wise monitoring and help pinpoint specific emission sources within the plant. In some facilities, automated control systems link gas detectors with ventilation systems or chemical feed controls, allowing for dynamic adjustments based on real-time pollutant levels.

Regulatory Guidelines and Compliance

With increasing awareness of air pollution from wastewater treatment plants (WWTPs), regulatory bodies around the world have laid down strict emission standards to protect public health and the environment. Staying compliant isn’t just about avoiding fines; it’s about running a responsible, sustainable operation.

Global Emission Standards

Agencies like the United States Environmental Protection Agency (USEPA), the European Union (EU), and India’s Central Pollution Control Board (CPCB) have set guidelines for controlling air emissions from WWTPs.

- USEPA (40 CFR Part 63, Subpart VVV): Limits hazardous air pollutant (HAP) discharges into wastewater systems, including strict thresholds for volatile organic compounds (VOCs) and hydrogen sulfide (H₂S).

- California Rule 1176: Specifically targets VOC emissions from wastewater systems in petrochemical facilities, mandating closed systems for primary treatment and VOC limits under 500 ppm.

- EU Best Available Techniques (BAT): Emphasizes continuous monitoring, odour management, and VOC capture for large municipal and industrial WWTPs.

- CPCB (India): Recommends odour control and ambient air quality limits near treatment plants, though enforcement is often local body-dependent.

Industry Best Practices

Beyond regulatory mandates, many WWTPs are adopting proactive emission management strategies:

- Installing real-time monitoring systems for gases like CH₄, H₂S, NH₃, and VOCs.

- Using biofilters, scrubbers, and covered tanks to minimize gas release.

- Following multi-level calibration of sensors for data accuracy as per U.S. EPA protocols.

- Implementing automated alerts and AI-based forecasting to predict emission trends.

- Conducting regular odour audits and community engagement to build trust and transparency.

By aligning operations with both regulations and best practices, WWTPs can significantly reduce emissions, improve operational safety, and support broader climate goals.

The Road Ahead: Innovations and Future Outlook

As wastewater treatment plants face growing pressure to reduce emissions and improve air quality, the future lies in smarter, data-driven solutions. Advancements in technology, policy, and public awareness are shaping a more sustainable path forward.

Role of AI, IoT, and Predictive Monitoring

Emerging technologies like Artificial Intelligence (AI) and the Internet of Things (IoT) are revolutionizing how we monitor air quality in WWTPs.

IoT-enabled sensors allow for continuous, real-time tracking of gases such as methane, ammonia, and VOCs across multiple points in a plant. When paired with AI, this data can be used for predictive analytics, spotting emission trends before they become violations.

For example, AI models can forecast high-risk periods based on weather, operational load, or previous data patterns. This enables proactive mitigation, optimized ventilation, and improved process control, reducing both emissions and operational downtime.

Need for stricter enforcement and awareness.

While technology is advancing, there’s still a gap in regulatory enforcement, especially in developing regions. Many WWTPs operate without formal emission limits or monitoring frameworks. Strengthening policy guidelines, enforcing compliance, and increasing public and industry awareness are key to driving real change.

A clear example of regulatory gaps turning into legal and environmental issues is Ireland’s recent situation. The country is at risk of facing EU penalties for failing to meet wastewater treatment standards, with dozens of areas discharging untreated or inadequately treated water into the environment.

Community engagement, odour complaint tracking, and transparent reporting can also push plants to operate more responsibly, turning compliance into a shared environmental commitment rather than a checkbox.

Conclusion

Wastewater treatment plants (WWTPs) are essential for public health and environmental protection, but they also release a variety of air pollutants, including methane, hydrogen sulfide, ammonia, VOCs, and carbon dioxide. These emissions, though often overlooked, contribute to climate change, degrade local air quality, and can have serious health impacts on nearby communities and plant workers.

As regulations evolve and environmental scrutiny increases, real-time air quality monitoring is no longer optional. It’s a critical part of responsible wastewater management. With sensor technologies capable of detecting gases at parts-per-billion levels and IoT-based platforms enabling continuous remote monitoring, WWTPs can now track emissions accurately and respond proactively.

Looking ahead, AI-driven analytics, predictive maintenance, and automated mitigation systems will play a bigger role in reducing emissions and optimizing plant performance. But technology alone isn’t enough. Strengthening regulatory enforcement, building community awareness, and promoting data transparency will be key to ensuring WWTPs are both efficient and environmentally safe.

Much like air quality monitoring in waste management facilities, integrating advanced monitoring into WWTP operations is a crucial step toward reducing emissions and safeguarding both communities and the climate. By embracing innovation and accountability, wastewater treatment can move toward a future where it not only cleans our water but also protects our air. Pure Water, Clean Air.