It would be fair to say that mining is the backbone of the manufacturing and infrastructure sector.

Mining is the process of extracting minerals from the earth. It requires cutting-edge technology, skilled labourers, government approvals, and much more. But what exactly are these minerals that the miners are extracting? Well, they are concentrated in natural rock and sediment deposits, known as ores. And the higher the ore grade, the more concentrated the desired minerals are.

For example, magnetite is the finest ore for iron extraction, with a total iron content ranging from 68-71%.

But, mining is not the only way miners can extract minerals from the earth’s surface. There is another process similar to mining – Quarrying. This process extracts minerals primarily for construction materials, like gravel, sand, and limestone. Quarrying is usually associated with open pit mines, open cast mines, and excavation of shallow deposits.

Global Demand & Extraction

The world is growing towards being a smart world and so is their demand for energy. With a focus on clean energy, we are seeing a significant increase in the need for metals. According to the International Monetary Funds, ‘A typical electric vehicle battery pack, for example, needs around 8 kilograms (18 pounds) of lithium, 35 kilograms of Nickel, 20 kilograms of manganese and 14 kilograms of cobalt. Likewise, charging stations require substantial amounts of copper. And for green power, solar panels use large quantities of copper, silicon, silver, and zinc. At the same time, wind turbines require iron ore, copper, and aluminum.’

Iron, aluminum, and copper are among the most mined metals in the world. And it’s no surprise that some of the largest mining companies, like BHP, Rio Tinto, Glencore, and Vale, are at the forefront of these significant and extensive mining operations.

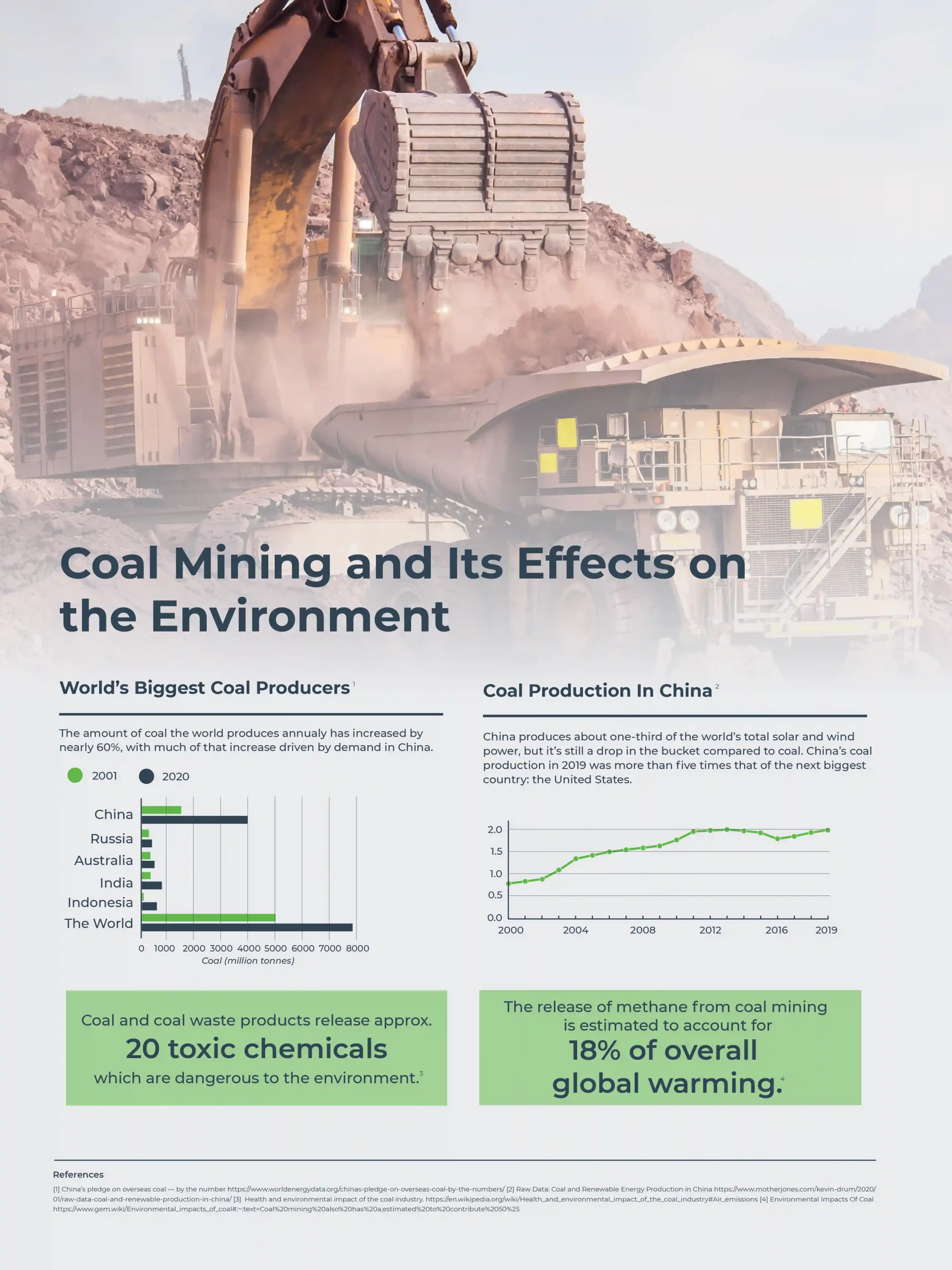

But we must also consider the impact of this increased demand for minerals on the environment. Mining can have significant environmental consequences, from water pollution to soil erosion. It’s essential that these operations are conducted sustainably to minimize their impact on the environment.

So, as we move towards a cleaner energy future, we must be mindful of the impact it has on the world around us. We need to balance the need for minerals with the need to protect our planet.

Chief Mining Methods

Mining is done using different methods. Each method is uniquely suited to extract specific minerals and metals from the earth. The four primary mining methods are:

- Surface Mining: This method is one of the most cost-effective methods that is useful to extract a wide range of minerals. It involves the removal of the top layer of soil and rock to access the valuable resources beneath. Surface mining is a method that we have been using for centuries, and it continues to evolve with new technology and practices.

- Underground Mining: This method is working deep beneath the surface to extract valuable metals like silver and lead. It is a bit more expensive than surface mining, but it’s worth it when you consider the value of the minerals being extracted.

- Placer Mining: This method is used to sift through riverine sediments to find valuable minerals such as gold, diamond, platinum, etc.

- In-situ Mining: This method uses science and technology to extract metals like uranium. It involves dissolving the minerals where they are found, pumping them to the ground, and processing them to extract pure metal.

How to Select an Ideal Mining Method

‘One mining method does not suit all types of mining. There are several factors:

- Which type of ore one wants to extract

- From where the ore is extracted

- Is mining activity in the decided area allowed by the government?

- Does the mining method suit regular compliances?

- Which grade of ore is supposed to be extracted?

And many more…

In short, each deposit is unique and requires careful consideration to determine the most effective and efficient method of extraction. Thus, the best mining method is usually the one that suits economical, technical, environmental, and productivity clauses.

Metal Extraction

Mining may be essential for the production of metals that are necessary for modern life, but it’s not without its consequences. The process of extracting minerals from the earth generates vast amounts of waste and pollution.

The initiation of mining involves clearing vegetation, crushing, blasting, and grinding, which can generate large amounts of dust in the air, posing health risks to workers and nearby communities.

The extraction process itself involves several steps, such as beneficiation, calcination, roasting, and smelting, which can also contribute to the environmental impact of mining.

Additionally, liquefication, vapor phase refining, distillation, electrolysis, and zone refining processes are used to obtain pure metals, but even these processes can generate their own forms of waste and pollution.

The mining industry generates massive amounts of waste, including overburden, tailings, slag, wastewater, and gaseous wastes. We must take steps to reduce the environmental impact of mining and find more sustainable ways to obtain the metals we need for modern life.

Consequences of Mining: Pollution

With the increase in mining industries and mining methods, the environment and health of people are suffering. Along with it, the pollution or the emissions of pollutants are high.

Mining is a polluting industry. It significantly affects the land, water, air, and soil quality through severe pollution. It also drives climate change and biodiversity loss.

Major air pollutants in the mining industry include dust as particulate matter and gases from various processes like smelting. Dust is the most significant air pollutant in the mining industry, released from several sources and mechanisms such as:

- Land clearing

- Removal of topsoil (during the opening of new mines)

- Removal of ore body/ore

- Drilling

- Blasting

- Crushing

- Screening

- Processing ore

- Loading & unloading material on site

- Subsequent transport off sites

In addition, wind action affecting stockpiles, dry tailings, exposed mining areas, and waste dumps generates significant dust.

The air in the mines can be contaminated by gases such as NOx, SOx, methane, hydrogen sulphide, carbon monoxide, and excess carbon dioxide. Due to the lack of ventilation and the confined nature of mines, gases build up. These gases create a combustible, explosive, and toxic environment within the mines. These gases are often referred to as Mine Damps. Several mine damps are responsible for creating this poisonous atmosphere – fired damp, black damp, white damp, and stink damp.

Additionally, due to constant drilling, crushing, and blasting processes, there is excessive noise pollution, especially in undermines. This can cause temporary or permanent hearing loss to the miners.

Does Mining Affect the Health of Miners?

The straight answer is yes. Miners are exposed to a significant amount of dust and gases that lead to respiratory diseases.

With prolonged exposure in opencast and underground mines, classical silica-induced pneumoconiosis is found in old miners.

Significant hazards that result from the exposure to functioning and abandoned tailings and mining-waste dumps are sulphur dioxide and metal-laden PM coming from smelter emissions and wind-blown dust.

Therefore, children living in settlements nearby or the path of the predominant winds from the abandoned mine dumps documented the maximum concentrations of metals in their bodies.

Government Standards

Government involvement plays a significant role in regulating the mining sector. It is also emphasized in the Sustainability Report on the Mining Sector published by the United Nations Environmental Programme (UNEP).

Refer to: Environment, health, and safety guidelines for base metal smelting & refining (Air emission standards for Nickel, copper, zinc, lead, and aluminium smelting and refining) by International Finance Corporation (World Bank Group).

Specific standards as prescribed by the central pollution control board of India:-

- In the case of calcination processes (e.g., aluminum plants), kilns, etc. PM emission shall be within 350 mg/Nm3

- For cement plants, the total dust (from all sections) should be 400 mg/Nm3 & 250 mg/Nm3.

- PM emissions up to 400 mg/Nm3 shall be allowed during oxygen lancing in the integrated steel & iron plant case.

- In the case of stone crushing units, the suspended PM contribution value at a distance of 40 meters from the controlled, isolated unit in the cluster should be less than 600 mg/Nm3. These units must also adopt the following measures:-

- Dust containment plus suppression systems

- Construction of wind-breaking walls

- Construction of the metalled roads within the premises

- Regular cleaning and wetting of the ground

- Growing a green belt along the periphery

Sustainability Report in the Mining Sector

The 2030 Agenda for Sustainable Development has 17 Sustainable Development Goals at its core. The activities of all the 17 SDGs are related to the mining sector to some level. Still, the most relevant is SDG 8 (decent work and economic growth) and SDG 12 (responsible consumption and production).

Sustainability reporting is an efficient tool to transfer information on environmental, social, economic & governance & performance measures from mining companies to their stakeholders.

- Mining companies and governments can consider modern technologies like air quality monitors for mining to track mining operations’ social and environmental impact. This can help transfer information from mining companies to the government, such as for SDG reporting, and other stakeholders, such as local communities. Open Data Principles are an emerging tool for governments to adopt for enhancing and streamlining information sharing.

- Voluntary Sustainability Initiatives are formed to enhance the sustainability & transparency of the different actors in the mineral supply chain.

- Governments can enhance the link between the Environmental Impact Assessment & the information reported in sustainability reporting of mining companies.

- While evaluating a mining project’s feasibility, the concerned party should take an integrated approach keeping in mind the environment.

Final Words

Since mining is an important industry of the global constitution and pollution is inevitable in mining, the only way to promote sustainable mining is by:

- Following regular compliance of government

- Install smart and robust air quality monitors for mining

- Automate dust suppression methods