Summary

The petrochemical industry plays a major role in the production of plastics, fertilizers, paints, and other everyday essentials; so naturally, it is a major contributor to industrial air pollution. Its emissions include various process steps from chemical processing, fuel combustion, storage losses, auxiliary systems, and even equipment leaks.

These emission sources release a wide range of harmful pollutants, including volatile organic compounds (VOCs), nitrogen oxides (NOx), sulfur dioxide (SO₂), particulate matter (PM), and methane, among others. Though their effects on air quality and health aren’t always visible, they can still be severe, as seen in the widely known case of Cancer Alley, Louisiana, where long-term exposure to petrochemical emissions has been linked to increased health issues among nearby residents.

The blog discusses how industries can adopt cleaner technologies, implement leak detection programs, and optimize operations to reduce emissions. Solutions like real-time air quality monitoring are already helping industries identify emission sources, stay compliant, and help in taking proactive actions.

By understanding the emission landscape and investing in the right tools, the petrochemical sector can move toward cleaner, safer, and more responsible production without compromising efficiency.

Air Pollution In Petrochemical Industries

From plastics, packaging, fertilizers, paints, to even medicines, petrochemicals serve as an essential for modern life. They’ve become so common in our daily lives that we often forget they exist until we realize what it takes to produce them.

Petrochemical plants run large-scale, complex operations involving cracking, reforming, treating, storing, and transporting raw materials and finished products. And each of these steps comes with an invisible cost of air pollution.

Unlike the smoke from chimneys or the emissions from cars, emissions from petrochemical units often go unnoticed. They escape silently from valves and seal, escape during storage, or are released during combustion and flaring. Still, they include some of the most harmful air pollutants: VOCs, NOx, SO₂, particulate matter, and even greenhouse gases like methane and CO₂.

So let’s take a look at how the petrochemical industry contributes to the air we breathe. Where do these emissions come from, and what can be done to reduce them?

How Does the Petrochemical Industry Contribute to Air Pollution?

The petrochemical industry commonly includes complex operations that convert crude oil and natural gas into various chemical products such as plastics, fertilizers, solvents, paints, synthetic materials and even medicine. According to the US EPA’s AP-42: Compilation of Air Emission Factors, the processes involved can be broadly grouped into five categories: separation processes, conversion processes, treating processes, feedstock and product handling, and auxiliary facilities. Based on this structure, air pollutant sources in petrochemical units are commonly categorized into process emissions, combustion emissions, fugitive emissions, storage and handling emissions, and auxiliary emissions.

1. Process Emissions

These emissions come directly from key industrial processes that convert crude oil and natural gas into required chemicals. This includes steps like cracking, reforming, isomerization, hydrotreating, and other chemical transformations.

Emission Source:

Vents are used to release pressure or gases.

Safety valves are used during emergencies or pressure surge

Sampling points where samples are taken for testing

This step releases pollutants such as VOCs, Sulfur compounds, NOx, CO, and greenhouse gases.

2. Combustion Emissions

It constitutes emissions coming from burning fuels to generate heat, steam, or power for the plant’s operations.

Emission Source:

Furnaces, boilers, heaters, and turbines, which are used to power process units.

Flares are safety devices that burn off excess or hazardous gases during upsets, shutdowns, or emergencies.

The outgoing pollutants are NOx, SO₂, CO, PM, CO₂, Black carbon/soot (flaring).

3. Fugitive Emissions

This refers to the accidental leaks of gases or vapors from pressurized equipment. They’re not released through a stack or vent; they simply escape from the system.

Emission Source:

- Valves, pumps, compressors, and flanges

- Pipe joints and seals

- Storage tanks and connectors

- Equipment under pressure

This releases small amounts of VOCs, HAPs, and Methane

4. Storage and Handling Emissions

These emissions occur any time materials are moved or stored in tanks. This happens when petroleum products or petrochemicals are stored, loaded, unloaded or transferred.

Emission Source:

- Storage tanks

- Loading and unloading operations

- Tank breathing: It refers to the vapors expand and escape due to temperature or pressure changes

This step mainly releases VOCs and other hazardous vapors based on what’s being stored or transferred.

5. Auxiliary Emissions

These are emissions produced by supporting equipment or processes which are part of the main processes. Though this is not a primary source of pollution it still needs to be overseen.

Emission Source:

Cooling towers

Wastewater treatment plants.

Sulfur recovery units

Boilers and backup generators

This mostly emits VOCs, H₂S, NH₃, SO₂, PM, and CO as a secondary source..

Major Air Pollutants from Petrochemical Plants

1. Volatile Organic Compounds (VOCs)

Source: Leaks, storage tanks, process vents

Impact: Cause smog formation; toxic and carcinogenic

2. Nitrogen Oxides (NOx)

Source: Fuel combustion in heaters, boilers, flares

Impact: Contribute to smog, acid rain, and respiratory issues

3. Sulfur Dioxide (SO₂)

Source: Burning sulfur-rich fuels, sulfur recovery units

Impact: Causes acid rain and breathing problems

4. Carbon Monoxide (CO)

Source: Incomplete combustion of fuels

Impact: Toxic; interferes with oxygen transport in the body

5. Particulate Matter (PM)

Source: Combustion units, flaring, material handling

Impact: Enters lungs; causes heart and respiratory diseases

6. Carbon Dioxide (CO₂)

Source: Fuel combustion in energy systems

Impact: Major greenhouse gas contributing to climate change

7. Methane (CH₄)

Source: Leaks from gas processing and pipelines

Impact: Potent greenhouse gas; contributes to global warming

8. Hydrogen Sulfide (H₂S)

Source: Crude oil processing, wastewater treatment

Impact: Toxic gas with strong odor; harmful to health

9. Ammonia (NH₃)

Source: Cooling towers, wastewater plants

Impact: Irritates eyes and lungs; contributes to secondary PM

10. Hazardous Air Pollutants (HAPs)

Source: Processing units, leaks, storage

Impact: Toxic or carcinogenic; regulated due to serious health risks

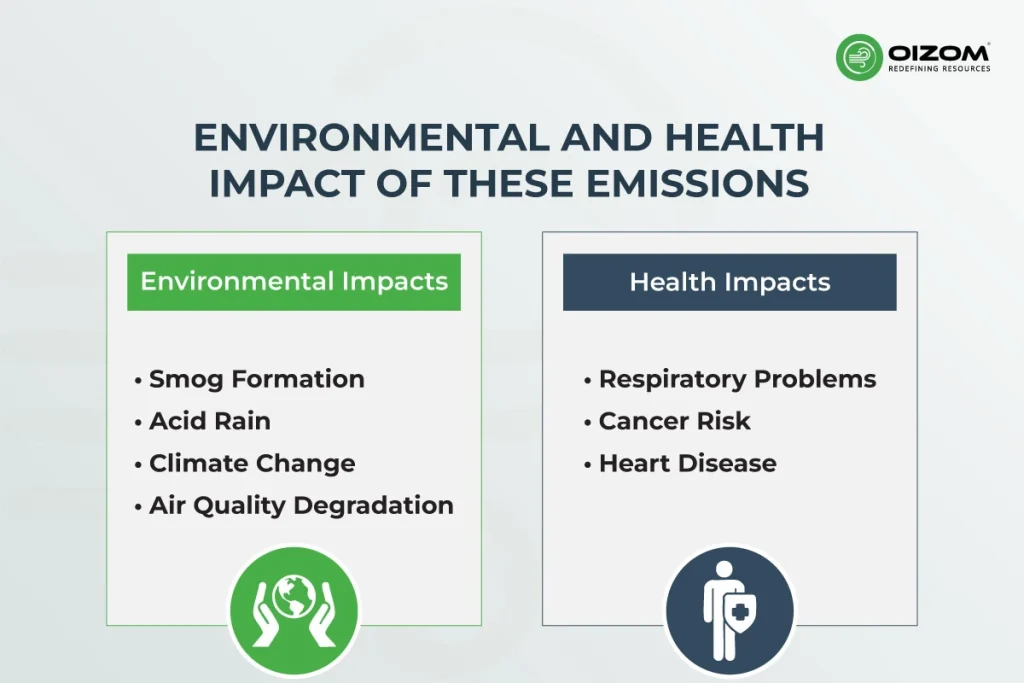

Environmental and Health Impact of These Emissions

Environmental Impacts

- Smog Formation: VOCs and NOx react to form ground-level ozone which is a major component of smog, reducing air quality and harming crops and vegetation.

- Acid Rain: Emissions like SO₂ and NOx lead to acid rain, which damages soil, water bodies, and plant life.

- Climate Change: Greenhouse gases like CO₂ and methane trap heat in the atmosphere, contributing to global warming.

- Air Quality Degradation: Particulate matter (PM), VOCs, and other pollutants lower overall ambient air quality, affecting ecosystems and public spaces.

Health Impacts

- Respiratory Problems: PM, SO₂, and NOx irritate the lungs and can cause asthma, bronchitis, and other breathing issues.

- Cancer Risk: Long-term exposure to VOCs and hazardous air pollutants (like benzene) increases the risk of cancer.

- Heart Disease: Fine particles (PM2.5) can enter the bloodstream and contribute to heart attacks, stroke, and other cardiovascular issues.

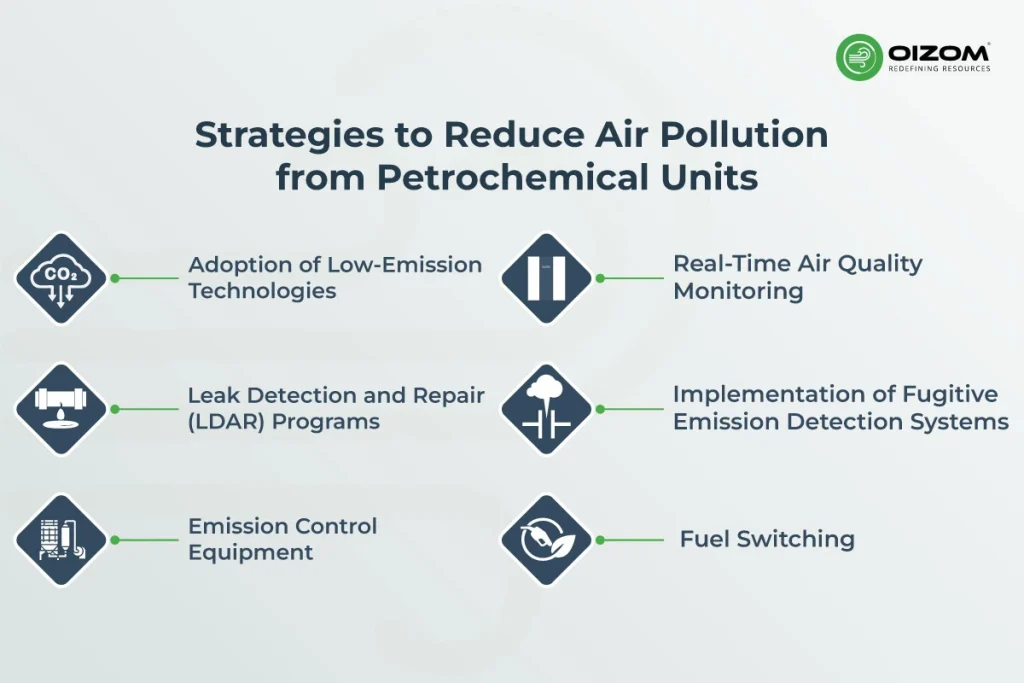

Strategies to Reduce Air Pollution from Petrochemical Units

Adoption of Low-Emission Technologies

Upgrading to cleaner process technologies, like low-NOx burners, flare gas recovery systems, and vapor recovery units, helps reduce emissions at the source.

Leak Detection and Repair (LDAR) Programs

Implementing regular inspections with advanced sensors or infrared cameras helps identify and fix fugitive emissions from valves, pumps, and pipelines.

Emission Control Equipment

Installing scrubbers, thermal oxidizers, electrostatic precipitators, and catalytic converters can effectively capture or neutralize pollutants before they’re released.

Real-Time Air Quality Monitoring

Using systems like Oizom’s environmental monitoring devices enables continuous tracking of pollutants, allowing for quicker response and regulatory compliance.

Process Optimization and Fuel Switching

Improving process efficiency and switching to low-sulfur or cleaner-burning fuels can significantly reduce combustion-related emissions.

Implementation of Fugitive Emission Detection Systems

Installing advanced detection systems such as infrared cameras, gas sensors, and real-time monitoring tools helps identify leaks early. This allows operators to repair faulty equipment quickly and prevent continuous emissions from valves, flanges, and pipelines.

Conclusion

Air pollution from the petrochemical industry is not just an environmental consequence but a direct result of operational inefficiencies and lack of awareness.. However, it’s not an unsolvable problem with the right approach, this can be tackled well.

Today, advanced tools and technologies are helping industries to go above traditional reporting. Oizom’s real-time monitoring systems empower facilities to track emissions at every stage from process vents and combustion units to leaks and storage losses. This feature allows for early detection, ensures regulatory compliance, and supports faster, data-driven decision-making.

Fugitive emissions no longer need to go unnoticed. Process inefficiencies can be identified before they escalate. And compliance doesn’t have to come at the cost of productivity.

As regulations tighten and accountability rises, forward-looking industries are already taking steps to modernize their environmental controls. Air quality is becoming a key metric in industrial performance and with solutions like Oizom, meeting that benchmark is not just possible, it’s practical.