Rock quarries are an essential part of our society, providing raw materials for various industries like construction, road-building, and manufacturing. However, these sites can pose a significant risk to the environment and public health if not managed properly, particularly in terms of air quality. This comprehensive guide aims to shed light on the importance of air quality monitoring in rock quarries, the environmental and health implications of poor air quality, and best practices to ensure efficient and effective monitoring.

Importance of Air Quality Monitoring in Rock Quarries

Air quality monitoring in rock quarries is not just an environmental concern—it’s a societal and economic necessity. Quarries release particulates and gases into the atmosphere that can harm human health, impair visibility, and contribute to climate change.

Constant monitoring allows for the early detection of potential issues, enabling corrective actions to be implemented promptly. It also ensures compliance with local, regional, and international environmental standards, protecting the quarry operators from potential fines or sanctions.

According to a study by the National Institute for Occupational Safety and Health (NIOSH), workers in rock quarries are more likely to develop respiratory illnesses than those in other industries. Regular air quality monitoring can protect these workers’ health and reduce healthcare and disability costs for employers.

Along with the air quality Monitoring Techniques, know more about Remote Air Quality Monitoring Systems for Quarries.

Environmental and Health Impacts of Poor Air Quality

Poor air quality can have a profound impact on both the environment and public health. Dust particles and gases released from rock quarries can contribute to air pollution, posing risks to nearby communities and ecosystems.

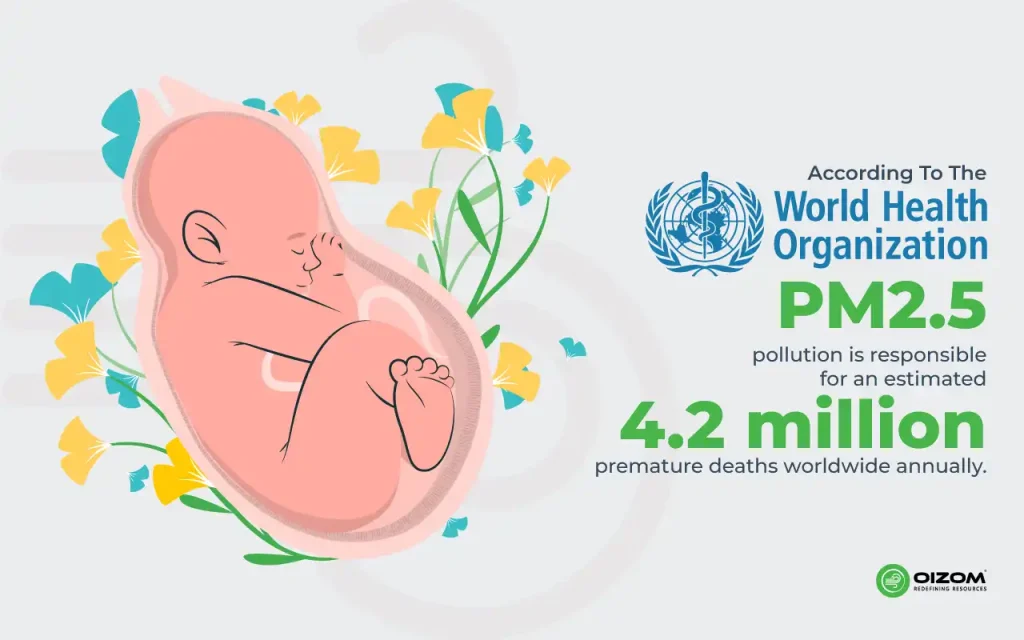

For example, fine particulate matter (PM2.5) can penetrate deep into the lungs, causing respiratory diseases such as asthma, bronchitis, and even lung cancer. According to the World Health Organization (WHO), PM2.5 pollution is responsible for an estimated 4.2 million premature deaths worldwide annually.

On an environmental level, pollutants can disrupt delicate ecosystems, reducing biodiversity and damaging plant life. Acid rain, which results from the emission of sulfur and nitrogen compounds, can also degrade infrastructure, reducing its lifespan and increasing maintenance costs.

Overview of Rock Quarry Operations

Rock quarries are large pits where rocks are extracted from the earth for use in construction and other industries. The operation process involves several stages, including prospecting, drilling, blasting, loading, hauling, crushing, and stockpiling.

Each stage of the operation process has its own unique set of environmental considerations, which can vary depending on factors like the type of rock being quarried, the methods used, and the local climate and geography.

Sources of Air Pollution in Rock Quarries

Two of the primary sources of air pollution in rock quarries are:

- dust emissions

- exhaust fumes.

Dust Emissions from Drilling, Blasting, and Crushing

Dust is generated at almost every stage in the quarrying process. Drilling and blasting dislodge large amounts of rock, creating a significant amount of dust. The crushing process, which breaks down the rock into smaller pieces, is another major dust producer. If not properly managed, these dust particles can become airborne, posing a risk to workers and nearby communities.

Exhaust Fumes from Machinery and Vehicles

Rock quarry operations rely heavily on machinery and vehicles, which emit pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. These emissions can contribute to smog, acid rain, and respiratory illnesses.

Air Quality Monitoring Techniques and Technologies

There are two primary types of air quality monitoring techniques:

- ambient air monitoring

- emission monitoring.

Ambient Air Monitoring

Ambient air Quality monitoring involves measuring the concentration of pollutants in the surrounding air. This is often done using air sampling devices that capture and analyze air samples. Data from ambient air monitoring can be used to assess the overall air quality in and around the quarry site and determine the potential impact on local communities and ecosystems.

Emission Monitoring

Emission monitoring, on the other hand, focuses on measuring the pollutants directly at their source, such as exhaust pipes of machinery or dust from drilling and blasting. This type of monitoring can help identify specific sources of pollution within the quarry, allowing for targeted interventions to reduce emissions.

Both of these monitoring techniques are facilitated by a range of technologies, from traditional filter-based samplers to advanced real-time sensors and remote sensing technologies. Innovations such as drones equipped with air quality sensors offer new possibilities for monitoring air quality over large areas and hard-to-reach locations.

Best Practices for Air Quality Monitoring in Rock Quarries

Air quality monitoring in rock quarries requires a multi-faceted approach involving careful planning, implementation of control measures, regular equipment maintenance, and workforce training.

Developing a Plan

The first step to effective air quality monitoring is to develop a comprehensive plan. This plan should identify potential sources of air pollution, set air quality targets, and establish procedures for regular monitoring and reporting.

Implementing Dust Suppression and Control Measure

Dust is one of the primary air pollutants in rock quarries. Implementing dust suppression measures such as water sprays, dust curtains, and enclosure of dust sources can drastically reduce dust emissions. Dust control measures, such as revegetation of exposed areas and paving of roads, can also help to minimize the amount of dust that becomes airborne.

Regular Equipment Maintenance and Upgrades

Machinery and vehicles are significant sources of air pollution in quarries. Regular maintenance can ensure that these machines operate efficiently and with lower emissions. Furthermore, upgrading to newer, more efficient, and cleaner equipment can significantly reduce a quarry’s environmental footprint.

Workforce Training and Awareness Programs

Ensuring that all workers understand the importance of air quality monitoring and know how to operate and maintain monitoring equipment is crucial. Regular training and awareness programs can help to foster a culture of environmental responsibility among the workforce.

Community Engagement and Transparency Initiatives

Engaging with the local community and being transparent about monitoring results can help to build trust and avoid conflicts. It can also provide valuable feedback that can be used to improve monitoring efforts.

Conclusion

Monitoring air quality in rock quarries is a critical task that requires careful planning, the right technology, and a committed team.

At Oizom, we empower our devices with our advanced and patented e-breathing technology. Along with providing real-time multiparameter monitoring, Oizom also provides real-time alerts and reports through its software – Envizom, which can be accessed from anywhere in the world. All of these help construction managers take quick action and create a sustainable and healthy construction site.

With proper measures in place, it is possible to reduce the environmental and health impacts of quarry operations, benefiting not just the quarry operators and workers but also the surrounding communities and ecosystems.

As we continue to rely on quarries for our construction and infrastructure needs, it’s important to remember that progress shouldn’t come at the expense of our health or the environment. With comprehensive air quality monitoring practices, we can strive for a balance that meets our needs while also preserving the quality of our air for generations to come.