Odour Monitoring Equipment

Odosense Pro

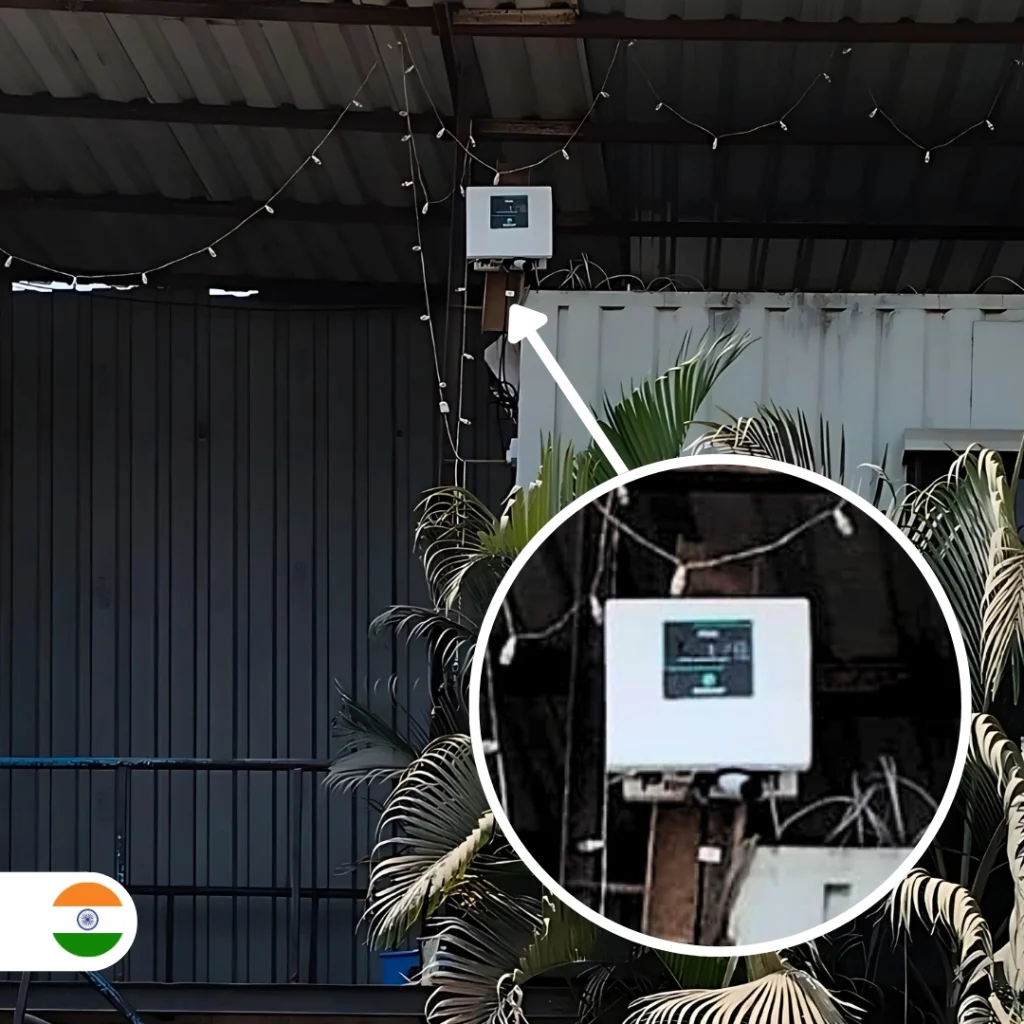

The Odosense Pro is our accurate odour monitoring equipment specially developed to monitor critical toxic and hazardous odour parameters. The Odosense pro is an industrial odour monitor for fenceline monitoring across various critical applications for instance oil & gas refineries, paper pulp, and agrochemical industries, pharmaceutical waste odour monitoring, etc.

Industrial fenceline monitoring is a legal and civic responsibility. However, while making the investments it is advisable to use systems that can offer accurate odour monitoring of several critical parameters in a single enclosure. Industrial fenceline monitoring can act as an alarm system in cases of accidental releases of pollutants. Through odour plume dispersion we can also backtrack the source of the odour and understand the industrial environmental health collectively.

Odosense Pro measures odourful parameters like Sulfur Dioxide (SO2), Hydrogen sulphide (H2S), Ammonia (NH3), Methyl Mercaptan, TVOC (Benzene, Toluene, Xylene), Formaldehyde (CH2O), Nitrogen Dioxide (NO2), Chlorine (Cl2), Temperature and Humidity.

Oizom’s odour monitoring equipment offers higher accuracy. Features like patented e-breathing technology, auto device firmware updates, and remote calibration capabilities ensure this. Additionally, our systems are backed with AI ML algorithms to understand odour levels and impact.

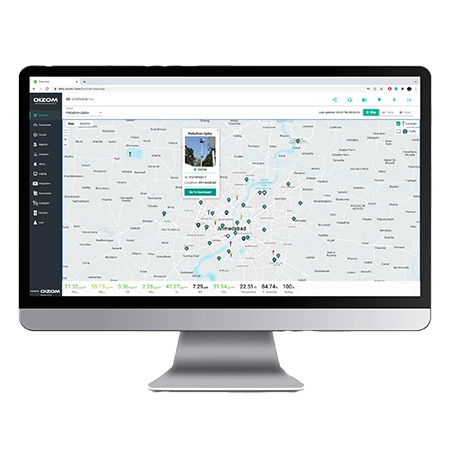

This Odour Monitoring Equipment can transmit data through various data communication modules like GSM, WiFi, LORA, etc to the Oizom cloud on real-time basis. Additionally, it has an inbuilt memory backup to ensure no data loss in case of network failure. This ensures the best device uptime. Oizom IoT Terminal – Envizom allows users to visualize data in the form of real-time dashboards. Upon collection on a dense network of data points and integrating weather data, users can also generate odour plumes and odour dispersion heatmaps. Similarly, by integrating data from the Odosense Pro onto 3rd party odour modelling platforms we can enable advanced analytics on the odour levels. Thus, the utilization of odour data extends to various industrial automation applications in an Industrial IoT (IIoT) environment.

- Integrated monitoring solution including important odourants like SO2, H2S, NH3, CH3SH, TVOC, CH2O, NO2, Cl2, Light, UV, Temperature, Humidity.

- Options to attach external modules from a wide range of parameters like Wind-speed, Wind-direction, Rainfall, Ambient Noise.

- Solar compatible solution with internal battery for more than 24Hours backup.

- Wide range of communication protocols to choose from (as per solution architecture and availability).

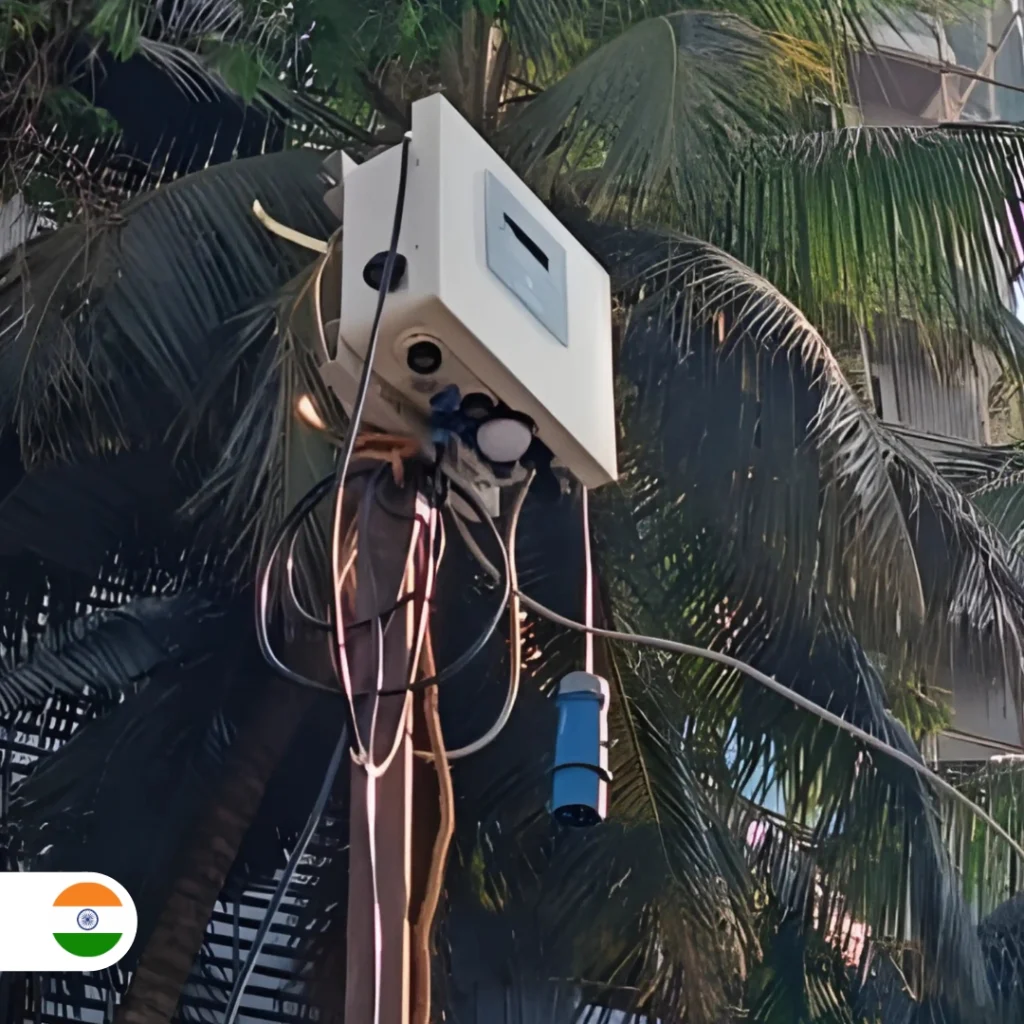

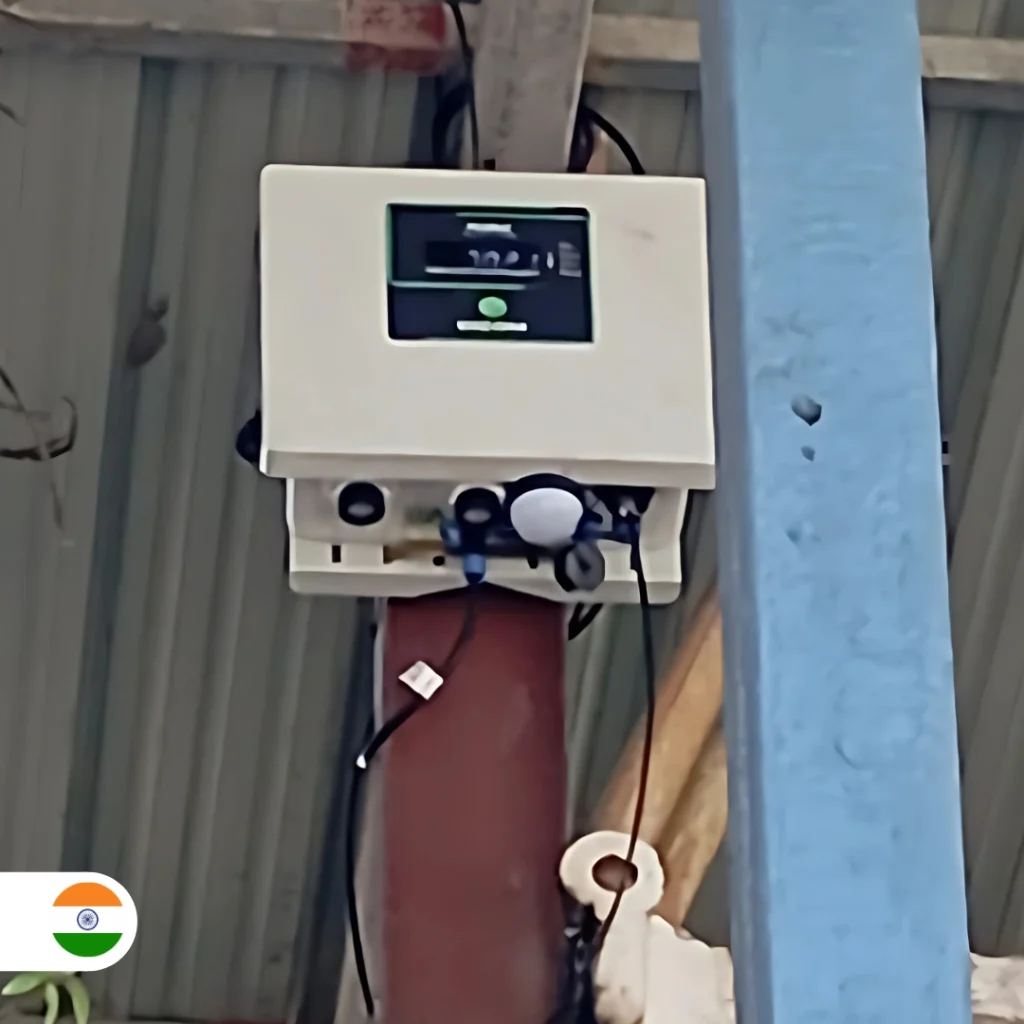

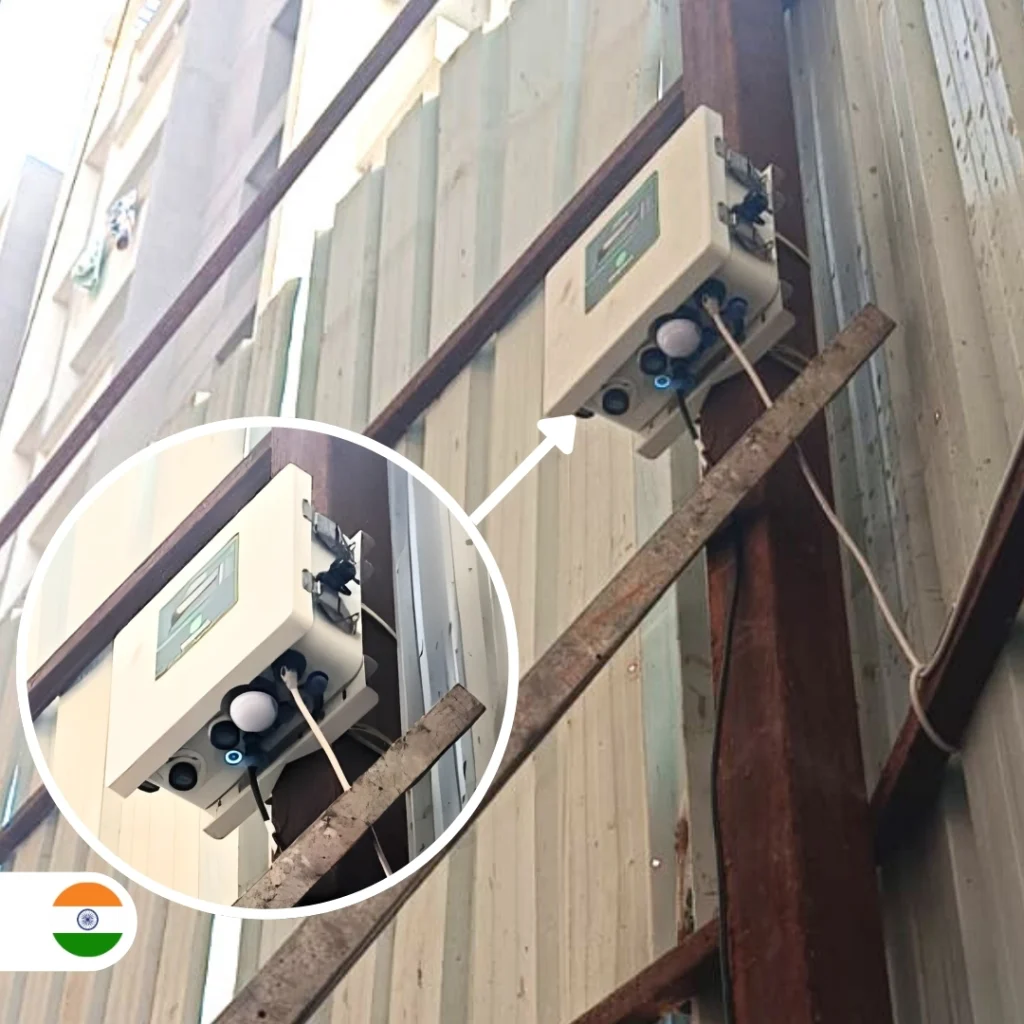

- Easy to install using plug-and-play design. Versatile mounting availability to install on pole, wall, fence, or any existing structure.

- The lowcost solution to deploy at multiple locations to establish a dense odour monitoring network.

- Using onboard calibration capability, an installed device can be calibrated on the spot without taking back to the laboratory.

- Real-time data transfer allows for appropriate environmental actions.

- Data availability in Odour Data Software Platform for further visualization and analytics.

- Odour Data API fulfills various applications and use-cases.”

- Patent Pending Technology: Works on innovative e-breathing technology for higher data accuracy

- Solar Powered: Capable of running independently on solar power

- Retrofit Design: Plug and play design for ease of implementation

- Compact: Light-weight and compact system installed at 12-15 feet (4-5 m) height

- Ultimate Durability: Made of high-grade engineering-metal and composite polymers for long life

- Real-Time Data: Continuous monitoring and real-time data transfer at configurable intervals

- Network Agnostic: Supports a wide range of connectivity options like GSM / WiFi / LoRa / NBIoT/ Ethernet

- Weatherproof: IP65 grade enclosure for endurance against harsh weather conditions

- Tamper Proof: Comes with a security system to avoid tampering/malfunction/sabotage

- Identity & Configuration: Each equipment carries its unique identity with geo-tagging through wireless configuration

- Over-The-Air Update: Automatically upgradeable from a central server without any onsite visit

- 3-Level Calibration: Can be calibrated by a third party nodal agency, reference station co-location, and spot calibration

Our odour monitoring equipment works on proven working principles for instance NDIR, PID, Electrochemical Analysis, Semiconductor, Optical Measurement. As a part of our proprietary ‘Micro Active Sampling’ (e-breathing technology), we have a sophisticated suction-and-exhaust system for air sample collection and monitoring inside a controlled environment. This isolates the effect of the external environment on measurement eventually to achieve 13% higher accuracy than the industry standards.

Electrochemical Analysis – An external potential is applied to the monitored gases. Identification of species like CO2, H2S, CH4, etc. depends on their oxidation or reduction potential.

NDIR – Monitored gases undergo Nondispersive Infrared Radiation. Here, the sample air is subjected to infrared radiation. Different gaseous molecules absorb IR at different frequencies. The amount of IR absorbed gives the volumetric concentration of each gaseous constituent.

PID – The photoionization detection method quantifies TVOCs present in the sample. Highly energized UV photons bombard the molecules, which ionize and make them positively charged. Subsequently, these ionized molecules, in return, produce an electric current which gives a volumetric concentration of the molecules. The higher the current generated, the higher is the gaseous concentration in the sample.

- GSM/GPRS: Second-generation digital cellular network for global coverage

- Ethernet: Wired local area network deployment capability for secure data transfer

- LoRa: Low Range, Low Power consumption transmission in sub-gigahertz radio frequency bands like 433 MHZ, 868 Mhz & 915 Mhz.

- Sigfox: Wide-reach & ultra-narrowband transmission for extensive area coverage with up to 140 uplink messages a day, 12 octet payload, and 100 bytes/second data rate.

- LTE: Standard wireless broadband communication for mobile devices and data terminals

- NB-IoT: High connection density capability with single Narrow-Band of 200kHz and enhanced Machine-Type communication LTE.

- WiFi: Wireless Local Area network deployment functionality based on the IEEE 802.11 standard.

- MODBUS: RS283 and RS485 based industrial grade communication

Odour Data Overview

Micro-analysis Dashboard

Historical Data Analytics

Odour Report

Smart Alerts

Historical Data-set Download

Odour Data is also accessible using secured HTTP/MQTT APIs. These APIs ensure data publishing on Public displays, Smart TVs, Websites (using the widget), and Mobile Apps.

By building conditional algorithms and logic on the real-time odour data, environmental automation is possible.

Using real-time odour and meteorological data, Environmental.Ai can perform odour impact assessment using dispersion modelling.

Product Applications

Do you know you can fully customize your air quality monitoring system with Oizom?

Schedule a call with our team of experts and get a customised solution for your air quality monitoring requirement.

Related Products

Air Quality Case Studies

Changing the way we monitor air quality

Contact us to learn more about our air quality monitoring systems and solutions.